Australia’s Therapeutic Goods Administration (TGA) has collated the public’s responses to proposed regulatory changes for personalized and 3D printed medical devices.

Overall, the consensus has been that the proposal needs “more clarity,” and the body, therefore, is putting a halt to regulatory development for 3D printed perosnalized medical devices in favor of seeking “Further stakeholder engagement” on the subject.

Industry’s impact

Initially called for in November 2017, the TGA’s public consultation collected a total of 24 submissions. The majority of these contributions were made by industry and industry representatives, including healthcare giant Johnson & Johnson, and the Australian contingents of Materialise and Stryker.

On the whole, stakeholders showed support for the TGA’s awareness and the need for an update on regulation. However, the responses have also given the TGA plenty of food for thought across the proposed changes.

Needs “more clarity”

As the consultation covers both personalized medical devices and 3D printed medical devices, it appears there is a need for further clarity on the definition of these two terms, and where they might overlap. Improvements were also requested to the definition of “a medical device production system” with examples.

Relating to Proposal 4: New classification for anatomical models and digital 3D print files, in particular, the TGA states that most submissions were in support of reclassification of such software and models. However:-

“Concerns were raised as to which anatomical models would be captured under the new provision,” “Some stakeholders also raised concerns about the potential additional cost and administrative burden a reclassification would entail,” and, “A few submissions debated whether the re-classification would be enforceable.”

Positive responses were also given to proposed regulation on devices containing “human original material,” i.e. stem cells.

Interestingly, some submissions also opposed an application and approval process for custom-made devices. The process would ultimately slow down delivery to the patient and therefore cancel out one of the technology’s main advantages.

The age of regulation

The TGA’s official statement on the submissions concludes, “Consistent throughout the submissions was a recognition of the need for the TGA to take action to improve the current arrangements for custom-made medical device regulation, which are too broad.”

In addition, “It was evident in the submissions that the current regulatory requirements are in many cases not fully understood. Greater explanation is also needed regarding the TGA’s proposals for change.”

In December 2017, the Dr. Scott Gottlieb Commissioner of U.S. Food and Drug Administration (FDA) released a statement about the agency’s commitment to a “new era of 3D printing of medical products,” with an update on its guidance.

To see what EOS, Materialise, 3DHeals and 3D Systems thought of the news, you can review our responses article here.

A full statement from the TGA can be read online here, along with each of the 24 responses from industry, practitioners, government and consumer representatives.

Through the International Medical Device Regulators Forum (IMDRF), the TGA has now opened another public consultation on Definitions for Personalized Medical Devices.

Subscribe to the 3D Printing Industry newsletter for updates on the latest innovative applications across medical and dental.

Prefer social media? You can also follow the 3D Printing Industry Twitter and like us on Facebook.

Sign up to 3D Printing Jobs to seek out new opportunities in this rapidly evolving industry.

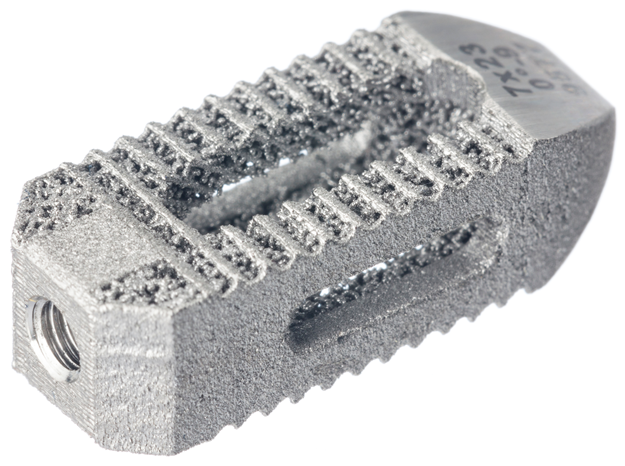

Featured image shows a 3D printed anatomical heart model. Photo via Materialise NV