British luxury sports car manufacturer Aston Martin has announced a new collaboration with fluid power systems manufacturer Domin and Cranfield University for the development of a “world-leading” suspension system that makes use of 3D printing.

Named the Full Active Suspension Technology (FAST) project, the partnership will leverage Domin’s patented technology, which involves additive manufacturing, to develop an industry-standard suspension system for the luxury car sector over the next six months.

The system prototype will then be fully fitted to one of Aston Martin’s luxury sports cars and real-world tested on a bespoke test rig. Upon successful completion of the project, the partners will then turn their attention to creating a production unit of the suspension system.

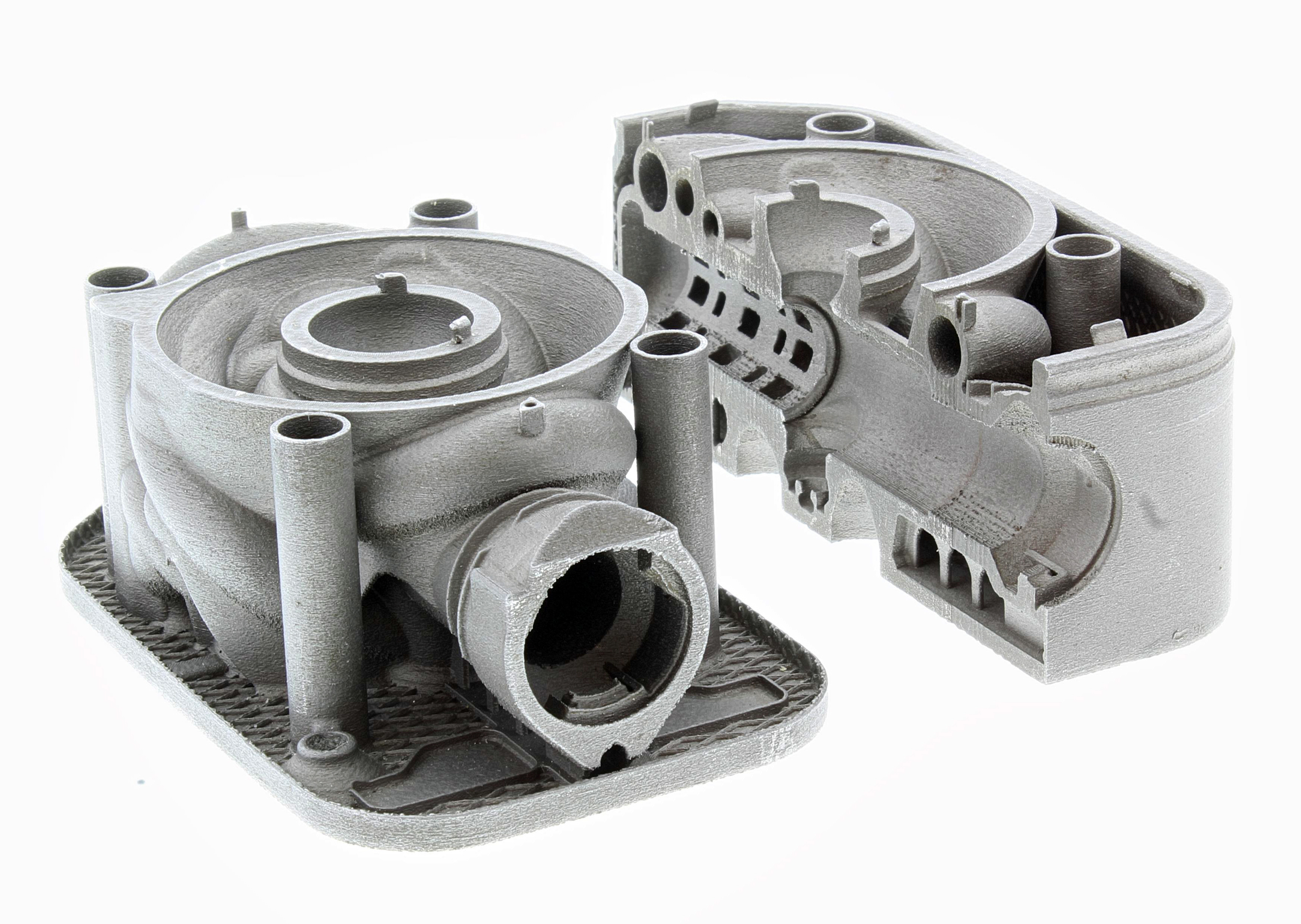

Domin’s patented valve technology

Fluid power systems utilize liquids or gases under pressure to generate and transmit energy, and are commonly used in markets spanning Formula 1, automotive, space, aerospace, mobile hydraulics, and industrial plants. Active systems such as these are able to adapt to constant changes in road surfaces more effectively than conventional suspension systems, which are big and heavy.

The design of the suspension system for Aston Martin will be based on Domin’s patented valve technology, involving a 3D printed core that contains 25 fluid galleries working in unison to transport hydraulic fluid throughout the system. The curvilinear nature of the unit intervals will be made possible by 3D printing and Domin’s advanced machining capabilities, which allow for the required mechanical properties of the suspension system. According to Domin, the FAST system will provide “infinite” variability in damping with a step response of just 0.015 seconds, and will weight less than 4kg per unit.

Domin has previously partnered with global engineering firm Renishaw to redevelop some of its fluid power system components, including its high-performance direct drive servo valves which are used for transforming signals into pressure. Domin leveraged Renishaw’s metal 3D printing technology to produce the redesigned valve, which was made smaller, cheaper, and more efficient.

Testing the FAST suspension system

Cranfield University will provide vehicle modeling and early-stage validation throughout the FAST project, which is funded by the Office for Low Emission Vehicles through the Niche Vehicle Network. Real-world testing of the system will then commence, with one of Aston Martin’s sports cars being fitted with the prototype on a bespoke test rig.

During the testing phase, the rig will replicate the precise modes of resonance and the conditions the unit will undergo during use, putting the suspension system’s high-performance capabilities to the test and ensuring its mechanical robustness. Once the six-month FAST project is concluded, the team will showcase the complete suspension system and reveal how it performed during the testing phase.

Looking ahead, the partners will leverage their engineering design and 3D printing capabilities to produce a production unit of the suspension system, with the ultimate aim of developing an industry-standard for suspension within the automotive sector.

Leveraging 3D printing for automotive

This is not the first time Aston Martin has dabbled with additive manufacturing, having deployed 3D printing in the production and design of its AM-RB 003 concept hypercar unveiled at the Geneva Motor Show in 2019. The company used 3D printing to manufacture both big and small parts within the interior of the vehicle in order to improve its lightweight properties, in addition to using CAD 3D modeling software to create intricate parametric forms within the car.

In addition, earlier this year product engineering firm CALLUM used a Makerbot METHOD X 3D printer to produce custom parts for a limited edition Aston Martin supercar, the Vanquish 25.

Elsewhere, some of the automotive industry’s biggest names have also embraced 3D printing in recent years to create enhanced end-use parts.

For instance, researchers from the Fraunhofer IAPT have worked with engineers from Fiat Chrysler Automobiles to 3D print an enhanced suspension part for one of its cars in order to cut production costs and lead times, while Italian luxury sports car manufacturer Lamborghini has used 3D printed components from Silicon Valley-based Carbon in the construction of its Urus Super SUVs.

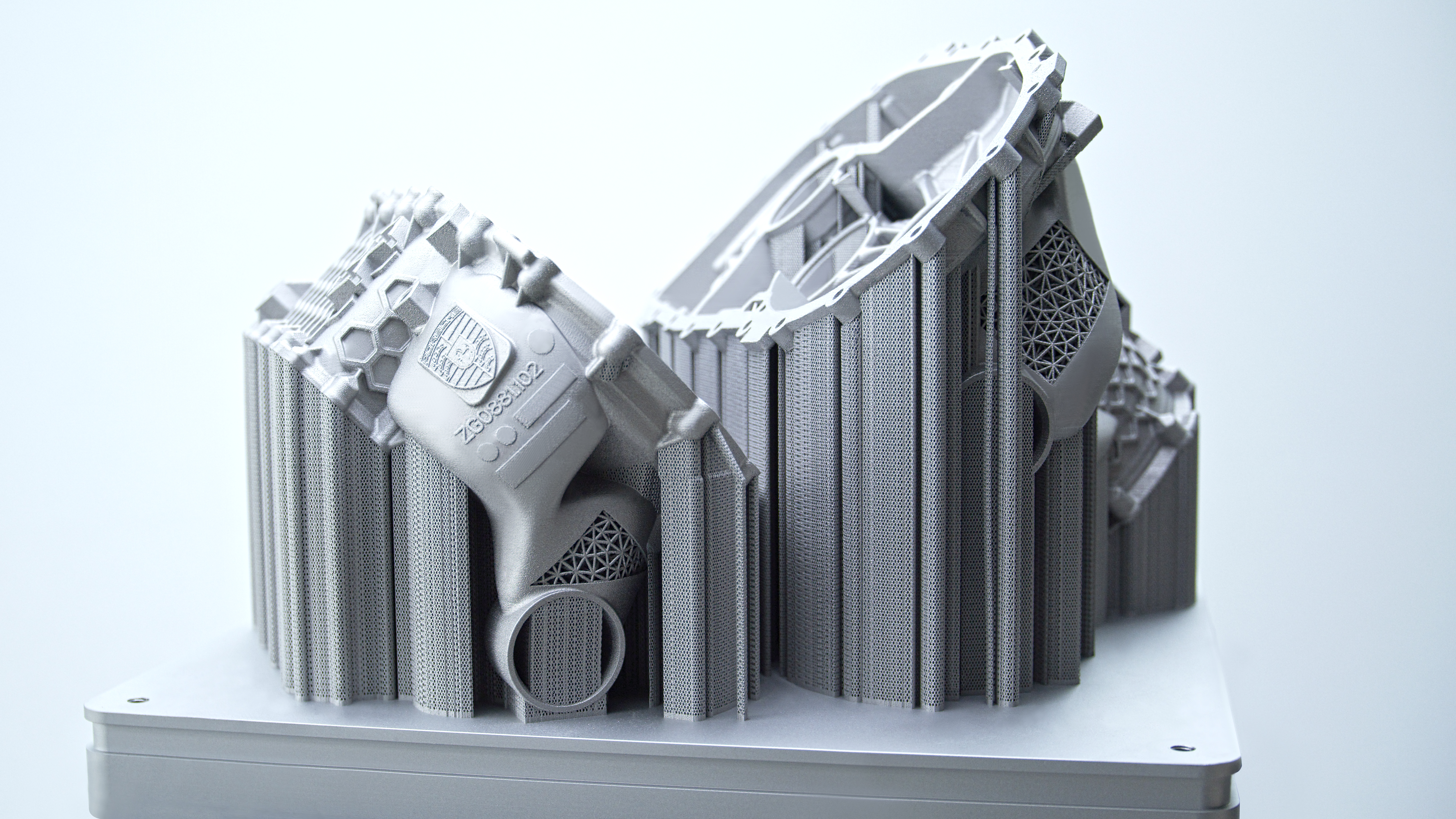

Meanwhile, Porsche has teamed up with machine tool producer TRUMPF and automotive parts firm MAHLE to 3D print pistons for the engine of its 911 supercar, and has also enlisted the services of 3D printer manufacturer SLM Solutions to print a proof of concept E-drive housing for the front axle of its sports cars.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Domin’s active suspension unit (shown fully retracted). Photo via Domin.