Global standards development organization ASTM International is to publish a standard practice outline for the use of powder bed fusion (PBF) 3D printing technologies.

The forthcoming document will help assure the technical repeatability of additive processes which remains one of the main barriers to the widespread adoption of the technology.

Popularizing metal 3D printing

ASTM International’s Committee F42 on Additive manufacturing Technologies was launched in 2009. Now comprising 400 members and 14 technical subcommittees, the organization’s additive standards cover everything from Test Methods and Design, through to Aerospace Applications and Strategic Planning.

Seven years after launch, in 2016, ASTM announced the International Organization for Standardization (ISO) had joined its efforts to develop standards for additive manufacturing.

At the end of March 2018, ASTM celebrated the launch of its Additive Manufacturing Center of Excellence, led by applications from EWI and an Auburn University-NASA collective.

Qualification of machines and processes

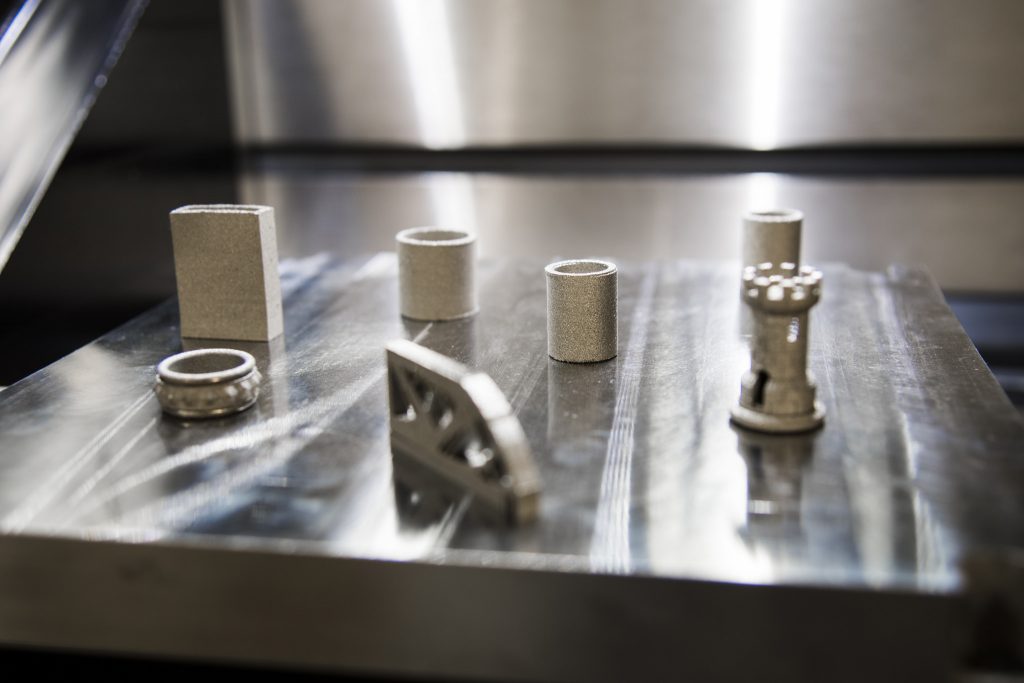

ASTM International’s latest standard for PBF will be known as an F3303. It will be used by manufacturers to help qualify machines and processes for component manufacturing in aerospace, healthcare, automotive and beyond.

Covering both electron-beam and laser based PBF technologies, the F3303 document has steps for the qualification processes such as SLM, EBAM, EBM and DMLS. It also contains outlines for the correct configuration and control of digital data used to print components.

According to Amir Farzadfar, ASTM member and additive manufacturing materials & process engineer at Corning Inc, “An additional standard is underway to support part qualification, quality assurance, and post-processing of powder bed fusion parts.”

To stay updated with all the industry latest development sign up to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Join 3D printing jobs for the latest opportunities in additive.

Adjudicate the winners of this year’s 2018 3D Printing Industry Awards before voting closes.

Featured image shows whore Selective Laser Melting (SLM) is one example of powder bed fusion 3D printing. Photo shows 3D printing CAPRI spinal implants. Via Youtube/K2M.