Architecture firms Arup, UK, and CLS Architetti, Italy, are 3D printing a concrete house as part of their 3D Housing 05 project, for this year’s Milan Design Week.

Designed to be disassembled and moved, the house will be 3D printed over the course of a week, on site at Milan’s Piazza Cesare Beccaria. It will feature a living area, bedroom, kitchen and bathroom over an area of 100 square meters. The architects intend the house to be a demonstration of the maturity of concrete 3D printing for architectural applications.

Collaborating to advance sustainable concrete 3D printing

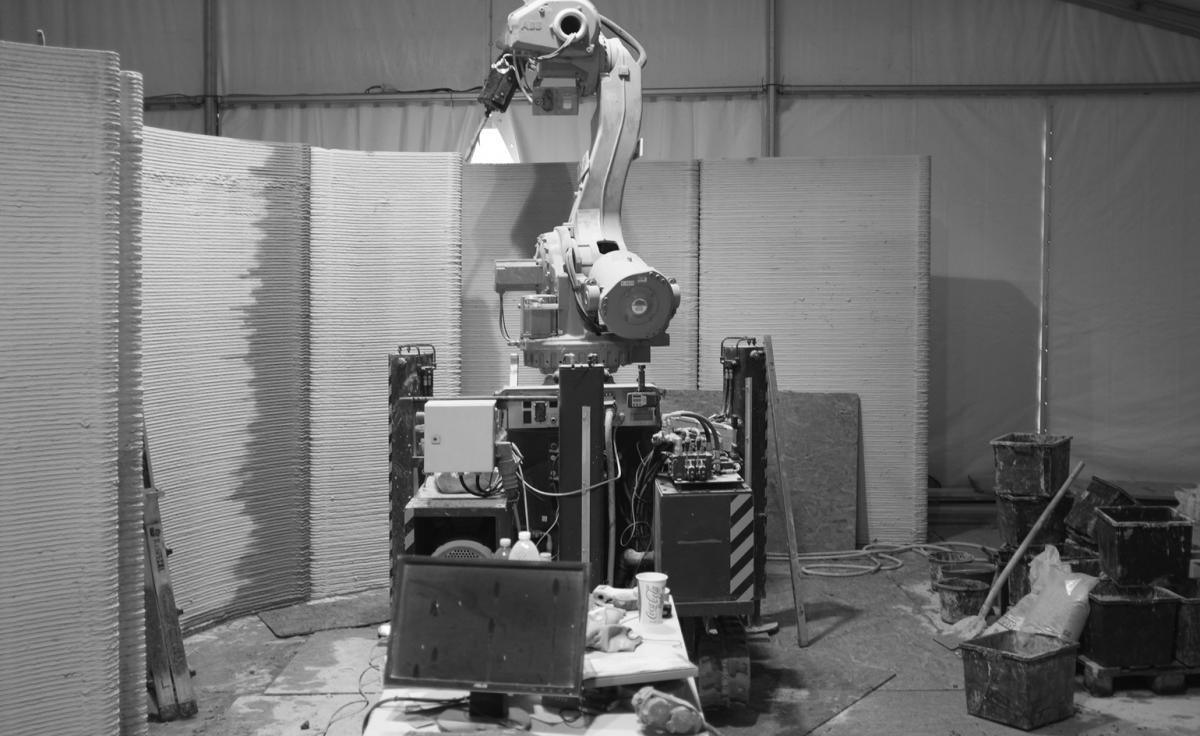

A robot 3D printing arm supplied by Dutch company CyBe Construction is producing the house’s walls, roof, window frames and doors. Cement is supplied by Italy’s Italcementi, a subsidiary of HeidelbergCement, both companies form the world’s second largest supplier of cement.

Last year, CyBe used their CyBe RC 3D printing arm to construct a 168 meter squared research facility for the Dubai Electricity and Water Authority.

Arup’s Europe Materials Consulting Lead, Guglielmo Carra, said “the construction industry is one of the world’s biggest users of resources and emitters of CO2. We want to bring a paradigm shift in the way the construction industry operates and believe that 3D printing technology is critical to making buildings more sustainable and efficient.”

Arup claims this method of 3D printing wastes fewer materials and benefits from the ability to produce complex structures like double curved walls. Using only the materials required (as the 3D file specifies the exact volume of material needed) will result in a lower cost – if everything goes to plan.

Concrete 3D printing integrating “new, more organic shapes”

In an interview with the architectural design website Wallpaper, Massimiliano Locatelli of CLS Architetti, said that his aesthetic vision for concrete 3D printing is “to integrate new, more organic shapes in the surrounding landscapes or urban architecture. I wanted to show a different way of using a printing machine and explore how a concrete house could create a dialogue with our memories of interior design, made of references to archetypes of the past”

Luca Stabile, Arup’s Italy Building Practice Leader, said “We believe 3D printing will contribute to breaking the conventional barriers in engineering and architecture. The use of new technologies alongside a new digital approach to the built environment will be instrumental to creating even more complex multi-storey 3D printed buildings.”

Elsewhere in the 3D printing construction sector, Siam Cement Group is developing what they call “Triple ‘S’” 3D concrete printing for the construction of larger structures. BAM Infrastructure worked with Eindhoven University of Technology to 3D print an 8 meter concrete bicycle bridge, also using the CyBe RC concrete 3D printer.

Keep posted on the latest 3D printing news from the Milan Design Week. Subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Vote for the 3D printing Innovation of the year in the 2018 3D Printing Industry Awards.

Post a job or advance your career in 3D printing now. Our 3D Printing Jobs service is now live.

Protolabs is sponsoring the 2018 3D Printing Industry Awards design competition. Enter now for the chance to win a Wanhao Duplicator 9 3D printer.

Featured image shows CyBe 3D printing arm constructing concrete walls for 3D Housing 05. Photo via CLS Architetti.