APWORKS has announced a new software tool for industrializing metal 3D printing – AMXpert.

The Taufkirchen, Germany based APWORKS has recently announced a restructuring plan that made them a subsidiary of Premium AEROTEC. Premium AEROTEC is a tier one supplier of metal components for Airbus aircraft.

Heraeus Additive Manufacturing will also support the AMXpert software tool. Heraeus Additive Manufacturing is part of the larger Heraeus Group. Headquartered in Hanau, Germany, Heraeus is a global technology company with over 12,000 employees. Heraeus is increasingly active in the additive manufacturing sector. Early projects included work on 3D printing amorphous metals in conjunction with Exmet.

Heraeus is also able to apply know-how from other divisions within the group to address issues within additive manufacturing. For example, using infrared heat to address the issue of residual stress.

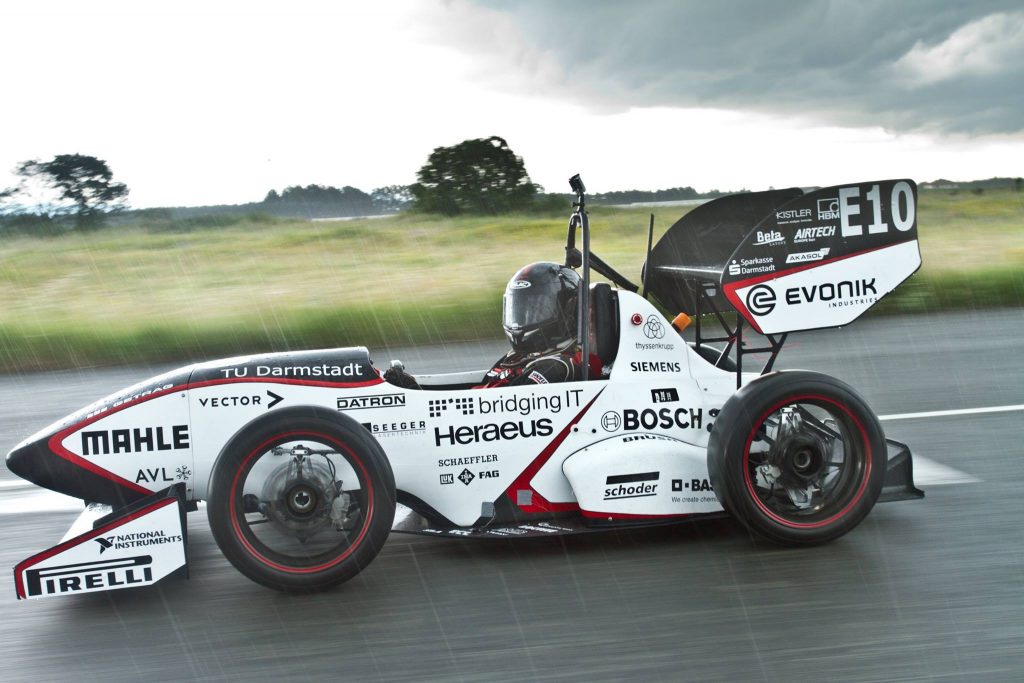

In related new, Heraeus will become a sales and cooperation partner to further develop the 3D printable aluminum alloys from APWORKS. Scalmalloy is a range of aluminum-magnesium scandium alloys that are attractive to many industries due to their weight to strength ratio.

On demand production with additive manufacturing

AMXpert is described by APWORKS as, “solving one of the central issues of additive manufacturing, namely, how to identify components with potential for metallic 3D printing.”

Sven Lauxmann, Chief Sales and Marketing Officer at APWORKS explains, “Through this collaboration, we—together with SAP and the Manufacturing Network—have taken the next logical step towards industrializing metallic 3D printing. By working as a team, we have developed a way for customers to test mass data for printability and to bring together the experts and the customers on the virtual platform. Worth noting here is a self-learning database, which is used primarily to intelligently assess printability, orientation, and thus costs.”

The SAP Distributed Manufacturing platform was launched in February 2017 for early access participants. TÜV NORD was one such early partner. The Hannover-headquartered technical services provider is helping to audit and certify the processes of 3D printing service providers in the network.

3YOURMIND is another enterprise tackling the question of how large organizations can assess the suitability of their inventory or spare parts for 3D printing. 3YOURMIND is also aiming to bring on demand production to an industrial level and working with New York based Identify3D has also added enhanced encryption for IP protection of 3D printable files.

An earlier collaboration between APWORKS and SAP was announced in July 2016 at that years Farnborough International Air Show in Hampshire, UK. 3D Printing Industry will be attending this years show at Farnborough to see how additive manufacturing is used by the aerospace sector. This year, over 60 exhibitors at Farnborough are applying industrial 3D printing for aerospace purposes. APWORKS will join their strategic partner, LPW on the Aerospace 4.0 Booth 5150 at Farnborough next month.

Subscribe to the 3D Printing Industry newsletter for all the additive manufacturing news from Farnborough. Also, follow us on Twitter, and like us on Facebook.

Looking for your next move in additive manufacturing? Use our free 3D Printing Jobs service to find or hire new talent across engineering, marketing, sales and more.

Featured image shows the Airbus APWorks Lightrider 3D printed using Scalmalloy. Photo by Michael Petch.