Additive Manufacturing Technologies (AMT), a UK-based provider of automated post-processing systems for the 3D printing sector, has launched its next-generation chemical vapor smoothing technology at Formnext 2021.

The PostPro Surface Finishing (SF) systems are a culmination of extensive customer feedback and more than two years of intense development, which led to a complete redesign of the company’s PostPro3D chemical vapor smoothing system. The new systems have been designed to reduce the overall part cost associated with the chemical vapor smoothing process and reduce cycle times by 25 percent.

“Our mission at AMT has always been to develop new technologies that create commercial breakthroughs and enable the mass adoption of additive manufacturing,” said Joseph Crabtree, CEO and Founder of AMT. “We first achieved this five years ago with the development of the world’s first chemical vapor smoothing technology, PostPro3D, delivering end-use-ready parts and to date is the most adopted chemical vapor smoothing technology on the market.

“The completely redesigned software and hardware of AMT’s new SF systems enable unsurpassed throughput rates at TCO costs and now allow additive manufacturing to be used as a viable alternative to traditional manufacturing.”

Driving AM industrialization

Since its founding in 2017, AMT has delivered its post-processing systems to more than 25 countries around the world and processed over six million 3D printed parts. Last month, the company raised £11 million in Series B funding to secure the rollout of its PostPro SF systems and support the delivery of its upcoming PostPro Digital Manufacturing System (DMS).

The funding round followed an earlier £2.5 million raised to help the company unlock the “full potential” of 3D printing post-processing, which was announced off the back of the firm’s partnership with multinational printing firm HP to provide end-to-end post-processing services for HP’s Multi Jet Fusion (MJF) printing technologies.

In addition to its ongoing partnership with HP, AMT has received an Innovate UK grant worth £87,000 to develop a new organic solvent designed specifically for the post-processing of elastomer materials.

Benefits of AMT’s PostPro SF systems

Since its initial debut at Formnext 2019, AMT’s PostPro SF systems have been further developed using feedback provided by 72 customers over a 50-month period. In the two and a half years since the systems’ introduction, AMT has intensely developed and redesigned them from the ground up with the primary aim of reducing the overall part cost associated with chemical vapor smoothing.

To achieve this, the PostPro SF systems have seen a significant reduction in consumable usage and an increase in consumable recycling efficiency, while reducing cycle time by up to 25 percent.

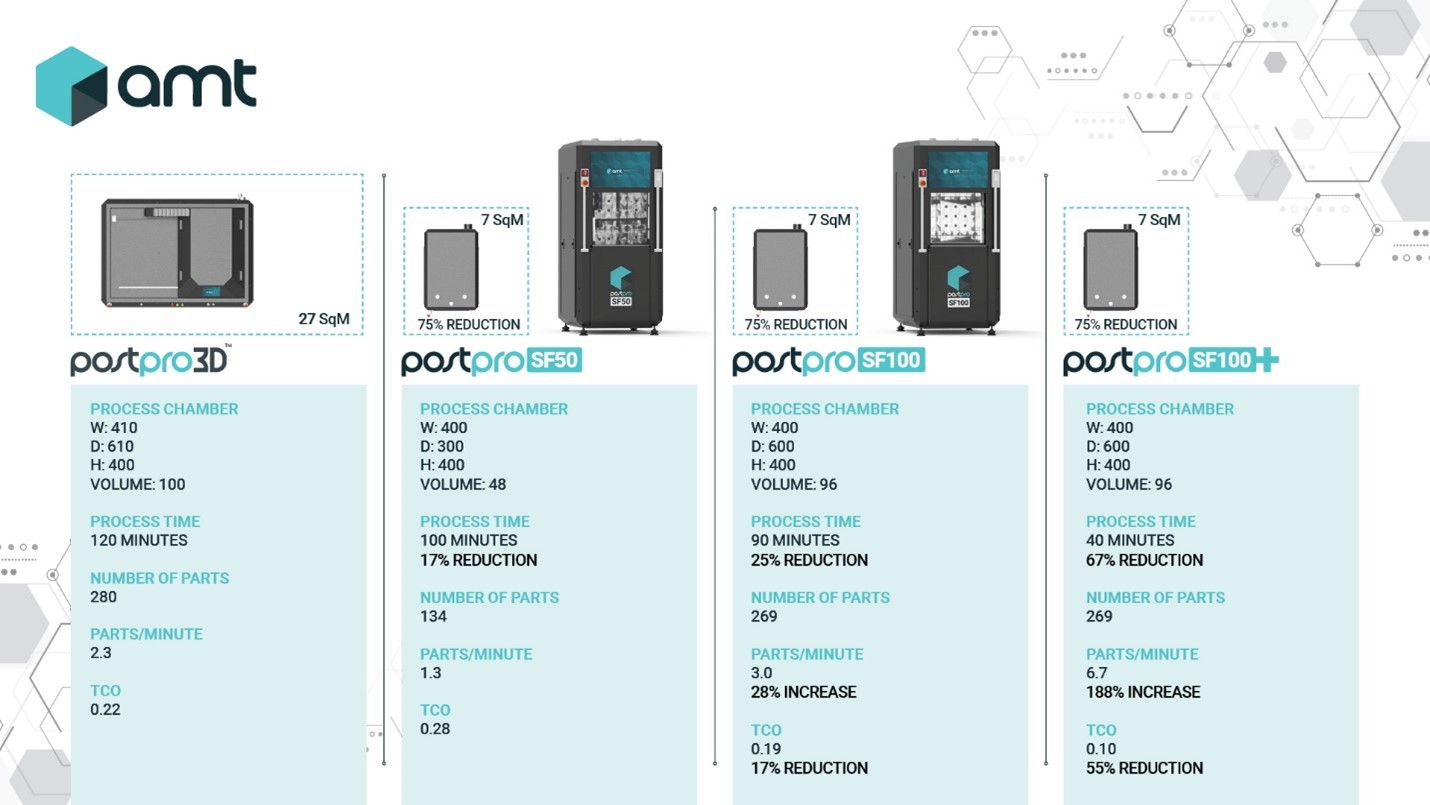

Select customers can also access an upgraded ‘+’ version of the SF system to reduce their processing time further still (67 percent) in order to increase their throughput. Additionally, the PostPro SF systems are designed to provide an enhanced user experience and allow for easier operation with a 75 percent smaller footprint.

AMT’s PostPro SF systems are currently available in two sizes: the PostPro SF50 and PostPro SF100. Ideal for prototyping and low volume production, the SF50 is equipped with a 50-liter processing chamber that allows users to process an average of 134 parts per run with a 100 minute cycle time.

The PostPro SF100, meanwhile, is designed for high volume production thanks to its 100-liter processing area. The larger chamber enables customers to process an average of 269 parts per run with a 25 percent reduction in process time, and a 17 percent reduction in TCO compared to AMT’s PostPro3D system.

Featuring the same processing capacity as the SF100, the upgraded SF100+ is engineered for continuous high-volume production with enhanced consumables recovery and reduced processing cycle time benefits. With the SF100+, users can take advantage of a 188 percent increase in the number of parts produced per minute and a 55 percent reduction in TWO compared to the PostPro3D.

Features of the SF systems

Each of the new PostPro SF systems has a more compact footprint, reduced by 75 percent compared to AMT’s PostPro3D system, to enable easier operation while taking up less floor space.

Being automation-ready, the new systems are designed to be easy to use. To this end, the systems feature a front-loading processing chamber and optional removable transportation stabilizer for ease of movement and positioning during installation.

Each SF system is equipped with a 1080p Full HD 21.5 inch intuitive touch screen interface with full online support for processing queries and maintenance, alongside automated consumables re-ordering and logging. The systems are “Industry 4.0 ready” and are able to be seamlessly integrated with external MES and ERP systems.

Regarding consumables, the PostPro SF systems are compatible with all of AMT’s finishing agents (FA 326, FA 26, and FA 9202) and include RFID canister recognition and controlled user access for improved safety. Additionally, the systems have a flexible power supply thanks to an optional internal transformer that reportedly suits most local power supplies and offers optimized low voltage power consumption.

AMT’s PostPro SF systems have been successfully tested with over 130 polymers and are capable of working with “all major OEM printer technologies”, ranging from HP to Desktop Metal. The SF50 and SF100 are now available for purchase, and customers attending Formnext this week can see the systems in action at AMT’s booth in Hall 12.1, stand C189.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows AMT’s PostPro SF100 system’s user interface. Photo via AMT.