Additive manufacturing software provider AMFG will supply a full suite of its Manufacturing Execution System (MES) to the Digital Manufacturing Center (DMC) in Silverstone, U.K.

Due to open in early 2021, the center will employ AMFG’s MES to support its additive manufacturing capabilities. The collaboration will also see the DMC become a development consultant to AMFG and contribute to the system’s innovation roadmap as it looks moves toward Industry 4.0.

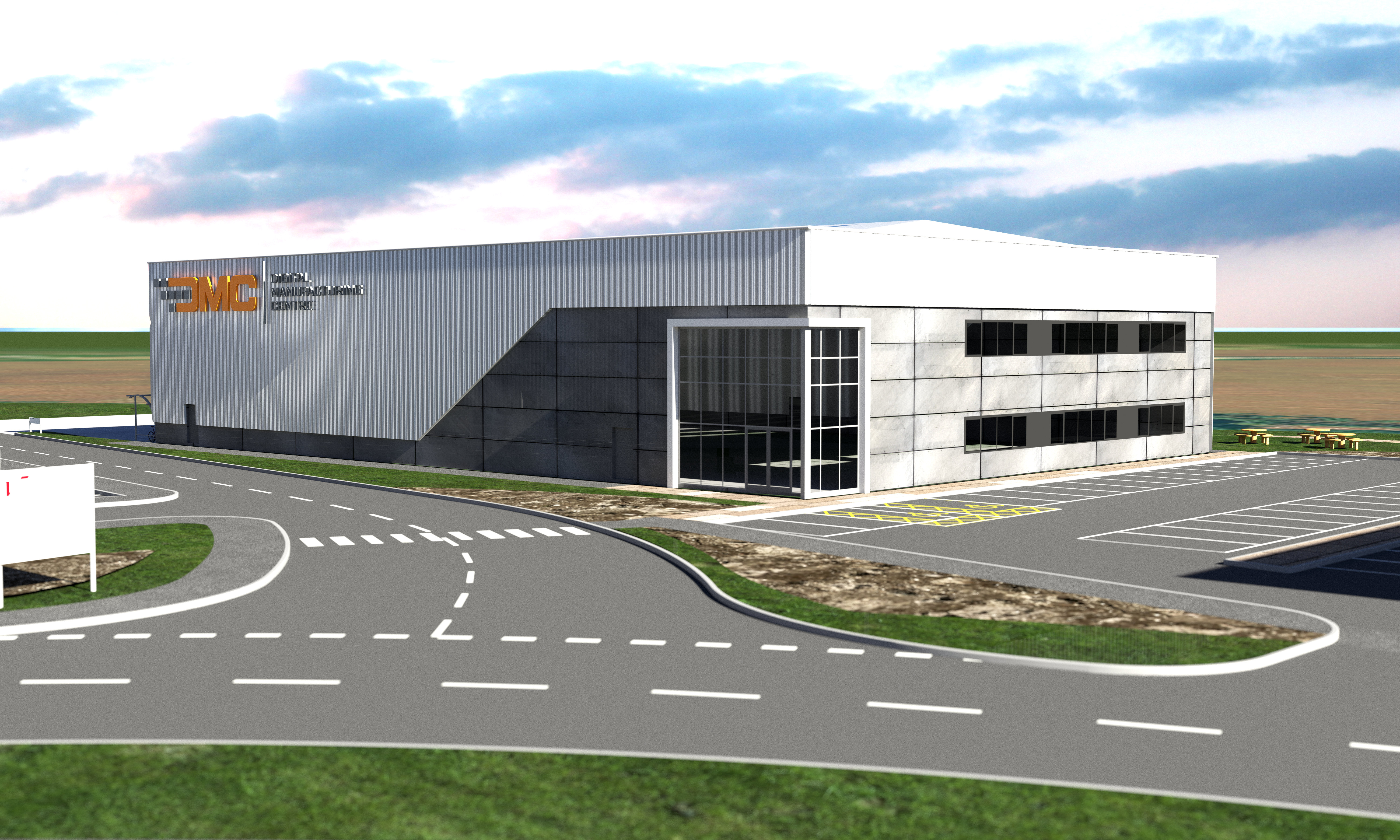

“The 2,000 square meter DMC facility will be full of engineers and machines providing complex and innovative solutions for the most advanced industrial customers,” said Kieron Salter, CEO of the DMC. “Integrating AMFG’s MES software will be instrumental in helping us establish a true digital manufacturing workflow to deliver on our goals.”

The DMC

Based in the UK’s Silverstone Park engineering center, the DMC will be a bespoke multi-million-pound digital manufacturing and innovation hub. The center is part-funded by South East Midlands Local Enterprise Partnership’s (SEMLEP) Local Growth Fund and led by KW Special Projects, a high-performance engineering consultancy, alongside other partners.

The DMC will integrate the latest additive manufacturing technologies to become a one-stop-shop for local companies wishing to access digital manufacturing capabilities and expertise. The center will provide design, engineering, manufacturing, inspection, and post-processing services, utilizing a variety of polymer and metal additive manufacturing technologies.

It is the aim of the center is to supports its customers in incorporating additive manufacturing into their production processes, and to scale up the existing operations of businesses already familiar with 3D printing.

The collaboration

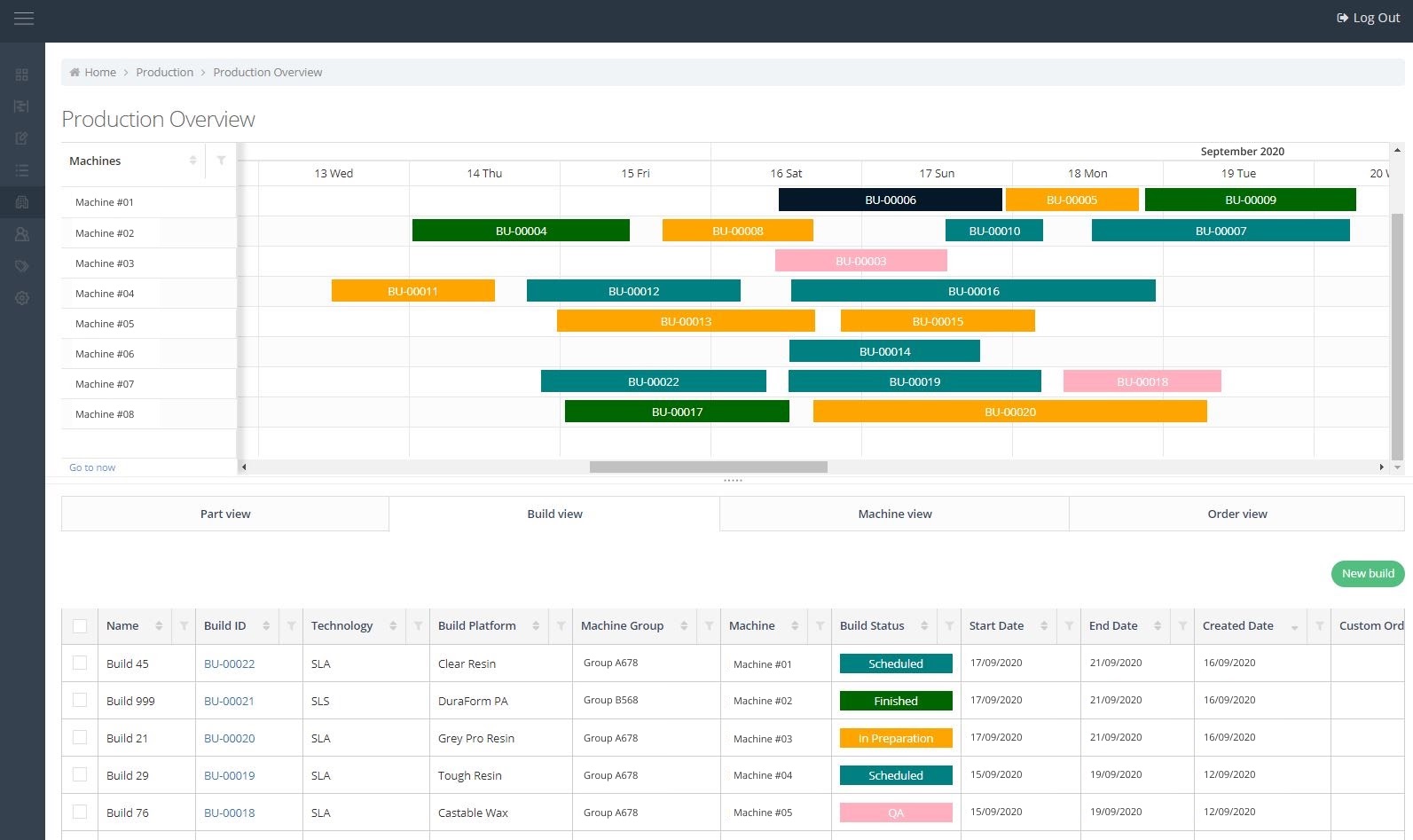

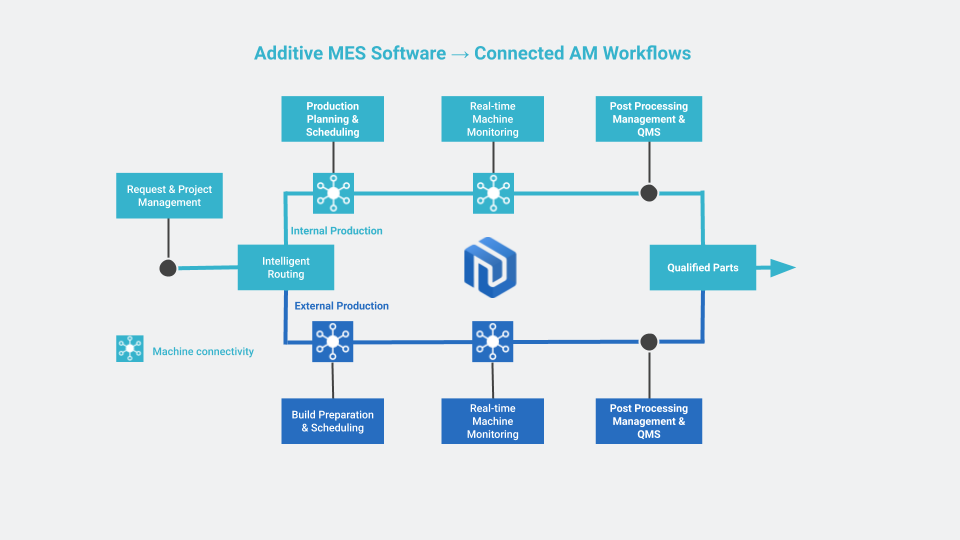

Once in operation, the DMC will deploy AMFG’s MES solutions to organize and oversee its ongoing additive manufacturing production activities. AMFG’s order and production management tools will aid the center’s engineers in tracking, prioritizing, and monitoring job orders, as well as preparing and scheduling builds.

The software will facilitate full process control and traceability of the 3D printing processes undertaken, and parts manufactured, at the center. Using MES, the DMC’s engineers will also be able to track KPIs in relation to Overall Equipment Efficiency (OEE), while the software’s data analytics tool will pinpoint bottlenecks and generally optimize the center’s processes.

“Digital manufacturing is burgeoning in the UK, and the launch of the DMC is yet another positive sign of this trend,” said Keyvan Karimi, CEO of AMFG. “Our goal is to support this trend with MES software, designed to digitize and streamline AM operations from end to end. We’re proud that the DMC facility will integrate the AMFG software and we look forward to driving the future of digital manufacturing together.”

AMFG’s MES

AMFG’s comprehensive workflow software, MES, was launched in 2018, as an AI platform with the aim to fully automate additive manufacturing in production.

Shortly after, AMFG secured £350,000 in funding from Innovate UK to further the development of its AI and machine learning technology for additive manufacturing. The firm channeled the funding into improving the analysis of parts during the quality assurance stage of a build, including the use of wide-ranging data sets and predicting failures before they occur.

In an interview with 3DPI earlier this year, Karimi spoke about the importance of connectivity to achieving scalable additive manufacturing workflows: “Connectivity is important for scalability, particularly as we look towards using AM for serial and end-part production,” he said. “For AM to make this transition, scalability – the ability to increase production, number of machines etc. – will be key.”

Last year, German 3D printer OEM, EOS, partnered with AMFG to enable streaming and connectivity for EOS machines using MES. The two companies collaborated on the project in response to the lack of connectivity across the 3D printing workflow, which they claim presents a barrier to those looking to adopt the technology.

Nominations for the 2020 3D Printing Industry Awards are still open, let us know who is leading the industry now.

The fourth edition of the 3D Printing Industry Awards Trophy Design Competition is now underway. Enter your design for the chance to win a CraftBot Flow 3D printer.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a render of the Digital Manufacturing Center. Image via AMFG.