The Advanced Materials + BioEngineering Research (AMBER) center, headquartered in Dublin, Ireland, is undertaking a project to develop 3D bioprinted implants for people suffering from osteoarthritis.

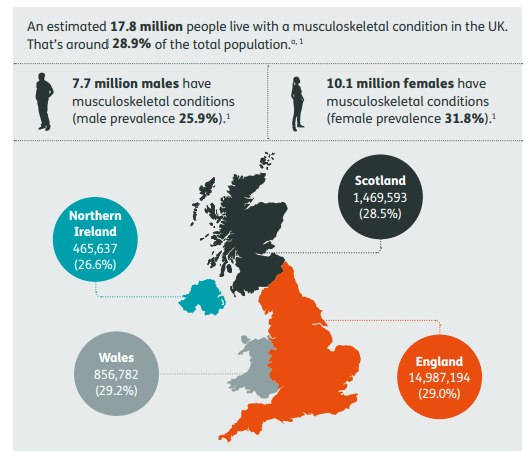

Made to regenerate rather than replace diseased joints, these implants could be an innovative solution for medical problems that affect over 900,000 people in the Republic of Ireland, and around 28.9% of the UK population alone.

Regenerate rather than replace

This project is the latest news from AMBER’s 3D bioprinting lab. With plans announced in 2018, the $4.9 million (€4.3 million) facility is the product of a collaboration between AMBER and multinational medical device and pharmaceutical company Johnson & Johnson.

In the project, the AMBER team plans to create a hybrid implant containing a titanium core. To promote regeneration, the implant will be seeded with patient tissue – presumable 3D bioprintied in the lab.

In an article in Irish Times Professor Danny Kelly, lead principal investigator on the project at AMBER, explains, “Theoretically at least we can begin to print new tissues or organs to potentially treat diseases like arthritis,”

“So instead of replacing the joint with a piece of metal we could replace it with a piece of lab-grown bone or cartilage that could regenerate that joint.”

Healing arthritis

Due to the prevalence of arthritis, cartilage is in fact a relatively popular area for 3D printing powered medical research. University Medical Centre (UMC) Utrecht in the Netherlands recently launched the 3D JOINT project for the purpose and, at Central Queensland University (CQUniversity), Australia, a team is investigating 3D printing devices laden crocodile protein.

3D printed titanium implants are also regularly receiving certification from the FDA.

For several years, AMBER has also maintained a partnership with Johnson & Johnson’s DePuy Synthes orthopaedic franchise, that owns custom implant 3D printing technology from Michigan-based Tissue Regeneration Systems. However it is unclear at present whether this technology will play any part in the project.

For more medical 3D printing updates sign up to the 3D Printing Industry newsletter, Also, follow us on Twitter, and like us on Facebook.

Search and post 3D Printing Jobs to seek opportunities and new talent across engineering, marketing, sales and more.

Featured image shows an AMBER researcher. Photo via AMBER