Researchers at the Egypt-based British University and Cosign Group have 3D printed an algae-loaded filament into an eco-friendly rooftop-mountable water irrigation system.

Built to address the vast quantities of wastewater produced by the country’s air conditioning units, the vase-like tubular device filters and redistributes any such byproducts, into watering its enclosed plant life. Given the challenges posed by climate change, the scientists see their façade as a more circular alternative to conventional glass surfaces, and the first in a new line of “living architecture.”

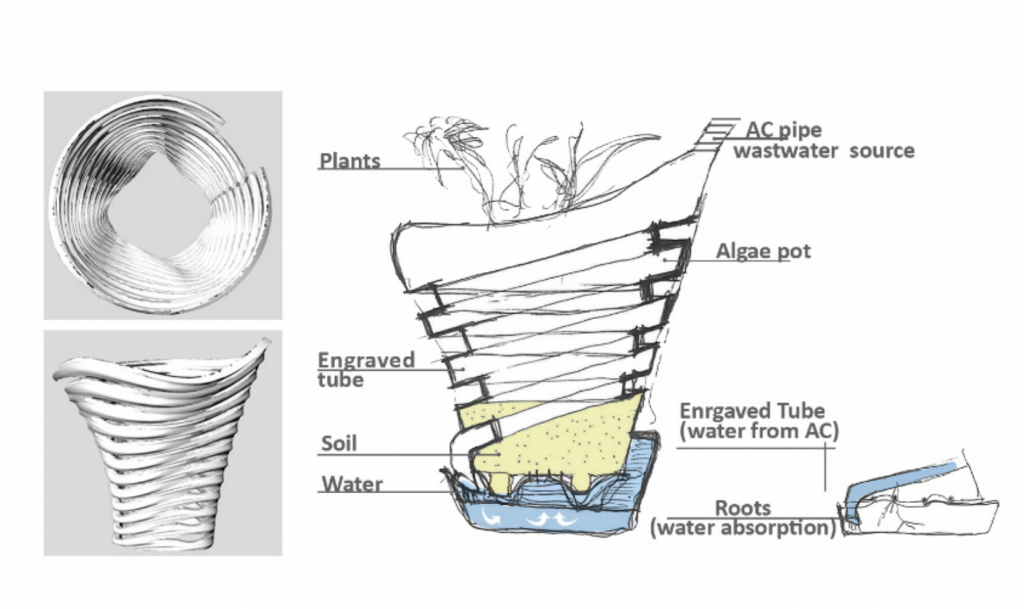

“In Egypt, during the extreme heat in summer, air conditioners produce a huge amount of outlet wastewater, causing great damage to buildings’ façades,” explained the team in their paper. “[Our] paper presents an innovative product solution made from algae, that aims to reuse this wastewater as a self-watering landscape façade element that acts as an irrigation system.”

Making construction eco-friendly

As climate change begins to cause extreme fluctuations in temperature around the world, countries are increasingly seeking to identify cleaner energy sources and more sustainable building materials. However, those living in large cities often try to deal with these thermal changes through the use of power-intensive ‘HVAC’ air conditioning units, which compound the issue by pumping out polluted water.

In Egypt’s capital Cairo, which is famed for its humidity during summer, the scientists have identified leaky AC systems as being a particular problem, as they’re often left unrepaired causing architectural damage. To combat this, the team suggest that algae, a bio-waste product that they say is “annoyingly available” along the Nile, can be reused as a circular basis for building water recycling units.

In the past, similar devices known as algae photobioreactor panels or ‘PBRs’ have been built, which use plants to absorb the sun’s rays and reduce a buildings’ heat, before reusing this energy to cultivate the same greenery, but the complexity and lack of regulation around such devices has so far prevented their wider adoption across the Egyptian capital.

Using 3D printing, on the other hand, the researchers now believe it’s possible to overcome these drawbacks, and build aesthetically-pleasing PBRs as a proof-of-concept for what they refer to as “regenerative building construction,” that are capable of collecting and purifying wastewater from AC units, while thermally-regulating buildings at the same time.

A sustainable 3D printed ‘façade’

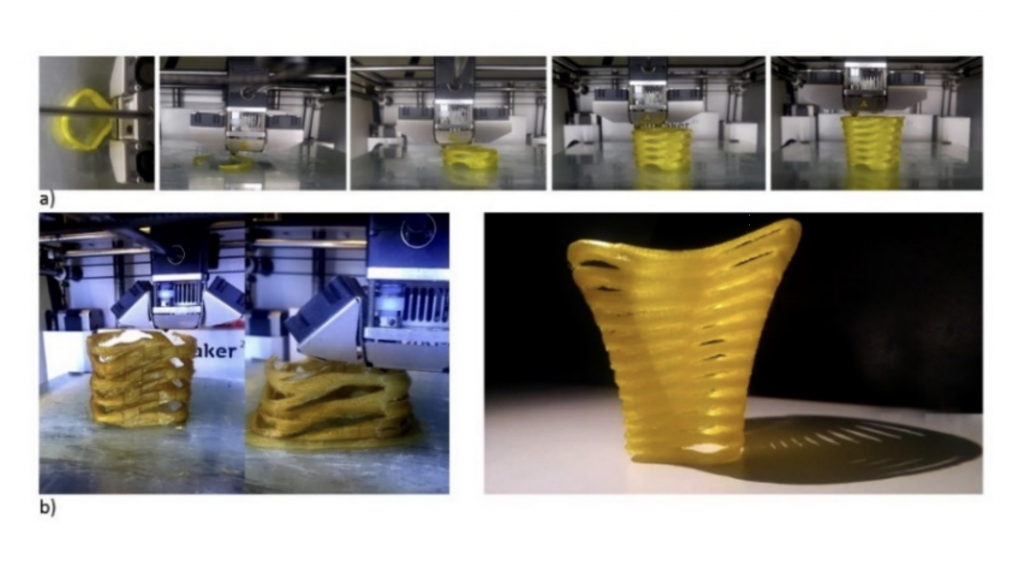

After modelling their irrigation system with Rhino generative design software, the team 3D printed it using the Ultimaker 2 and Monoprice MP Select Mini machines. In practise, they found that this was best achieved by producing a PLA prototype first, before using this to identify the ideal parameters for creating an algae-based unit without any supports.

Having achieved this, the scientists went on to 3D print a 40 x 20 cm prototype from an entirely biosourced material, composed of biopolymers and algae, developed by R&D lab Atelier LUMA back in 2017. The team’s final design featured an outer tube for collecting AC waste, that was patterned to aid water flowability, while its inner tube was built to cool these liquids down by the time they would be needed for irrigation.

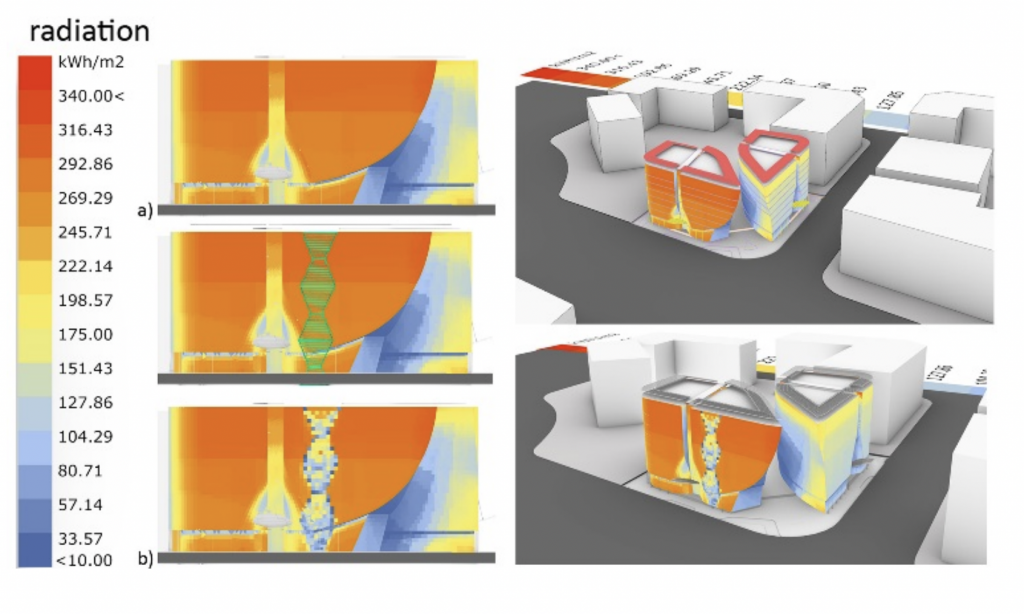

In order to assess the functionality of their ‘living architecture,’ the researchers subjected it to a simulated solar radiation test. Again, using the Rhino platform, the team were able to calculate the impact of exposing their water-filled device to the intense heat of Cairo during mid-July, finding that it was capable of absorbing the sun’s rays, reducing thermal radiation levels from 316.43 to to 80.71 kWh/m2.

If upscaled into building panels, the researchers therefore believe that their system could not only help reduce people’s reliance on AC, but cut their energy usage as well. While they concede that further cost-benefit analysis testing will be required before their devices can be scaled effectively, they also suggest that in future, 3D printing will be vital to unlocking more complex designs with end-use potential.

“[We have] demonstrated the possibility of 3D printing a watering system on a small-scale that can then be up-scaled as a bio-reactive green façade for self-controlled growth on buildings at an urban scale,” concluded the team in their paper. “The future of 3D bioprinting will allow anyone to customize and 3D print any element using any type of materials as simply as ‘baking bread.’”

3D printing in thermal regulation

Necessitated by the continually worsening climate crisis, 3D printing is increasingly being adopted to enable the construction of buildings that are less reliant on conventional air conditioning. Just last month, the UTS School of Architecture worked with BVN Architecture to 3D print an air conditioning unit with 90% less embodied carbon than usual.

Likewise, engineers at Microlight3D are currently developing a novel microstructured 3D printing material, which could eventually allow for the construction of ‘self-cooling’ buildings. Working as part of the EU’s Future and Emerging Technologies (FET) program, the firm aims to help combat the heat-wasting phenomenon known as ‘urban heat islands.’

Elsewhere, the likes of BigRep and BASF’s 3D printing arm Forward AM have launched a Concrete Formwork material, that’s designed to reduce construction waste while unlocking more intricate designs. Targeted towards current end-use applications, the firms say their filament enables complex buildings to be erected at a “fraction of the [current] cost.”

The researchers’ findings are detailed in their paper titled “Wastewater matter: From algae to bio-algae plastic 3D printed facade element,” which was co-authored by Deena El-Mahdy and Ahmed Khaled Youssef.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a diagram depicting the temperature of captured water cooling in the team’s 3D printed device. Image via the Materials and Contact Characterisation journal.