South African biotech startup Akili Labs has developed FieldLab, an accurate, affordable and portable 3D printed diagnostics lab that can cost as little as $1,500, or one-tenth of similar equipment.

The FieldLab was created by Akili Labs co-founders and Rhodes University Biotechnology Innovation Centre (RUBIC) graduate students Charles Faul and Lucas Lotter. Their aim is to give doctors and scientists a rapid and accurate means of identifying disease outbreaks on the spot.

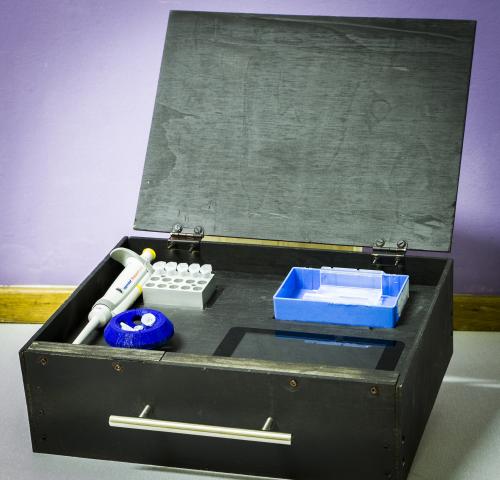

The FieldLab in a box

FieldLab is a rapid field-testing “lab-in-a-box.” It allows medical professionals in remote areas and conflict zones to access equipment typically found in state-of-the-art diagnostic laboratories. By testing for certain viruses, bacteria, and fungi on site, they can quickly identify an outbreak of disease and take the necessary measures before it spreads and becomes an epidemic.

The FieldLab consists of 3D printed equipment including a high-powered light microscope, a 3D printed centrifuge, a 3D printed PCR (Polymerase Chain Reaction) thermal cycler, and a visualization system. Additional modules, such as a specialist Zika Virus PCR kit, can be added if required.

The machinery may be powered by an integrated power supply and recharged using solar power, a 12V car battery or a 110V/220V AC power source.

Akili labs also successfully integrated a laminar flow system with UV workspace sterilization into FieldLab, improving the overall quality of the diagnosis performed. All equipment within the 3D printed FieldLab box can withstand rough transportation.

Akili Labs most recent estimates assert that comparable laboratory equipment costs between R100,000 ($7300) and R200,000 ($15,000). Conversely, 3D printed FieldLab equipment will cost between R15,000 ($1100) and R20,000 ($1500), or between R28,000 ($2040) and R30,000 ($2,200) with modular attachments.

In a statement, Faul noted the difficulties experienced by medical professionals across Africa, and stated that FieldLab was invented with the aim of bridging “the gap in health care experienced throughout Africa” with “low-cost lab equipment.”

National recognition

In September, Faul and Lotter beat 300 other startups to win a R50,000 prize ($3700) at the National Innovation Bridge Showcase for the competition’s “best prototype.” While the 3D printed equipment in this prototype was housed in a plywood box, the final boxes will make use of tough 3D printed resin.

Following this, Akili Labs won a further R500,000 ($37,000) first prize in the Innovation Hub’s GAP Bioscience awards in November. In a social media post, Faul claimed that following this latest award, Labs went on to receive a further one million Rand ($73,000) in seed funding over just three days. The funding that has been raised will now go towards producing a commercially viable product.

3D printing and aid

3D technology has also been used by charity Médecins sans Frontières to build functional hospitals quicker, while doctors from the Glia medical project in Gaza are 3D printing stethoscopes and other medical supplies that they are unable to acquire elsewhere.

Nominations for the second annual 3D Printing Industry Awards are now open. Make your selections now.

For more stories on 3D printing and biotechnology, subscribe to our free 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Featured image shows Faul and Lotter showcasing the prototype FieldLab at the Innovation Bridge Showcase. Photo via RUBIC.