A scramjet engine built by propulsion system manufacturer Aerojet Rocketdyne has been successfully flight tested as part of a US hypersonic missile research project.

By 3D printing the drive system, the firm is said to have been able to construct it using 95% fewer parts than were needed to build its previous iteration, which powered the Mach 5-capable United States Air Force (USAF) X-51A Waverider.

Developed via a military R&D program with the Defense Advanced Research Projects Agency (DARPA), Air Force Research Laboratory (AFRL) and Lockheed Martin, the company’s engine is designed to propel an air-launched missile system, that can be built and fired with greater efficacy than the weapons of US rivals.

“Aerojet Rocketdyne is well-positioned to support our nation’s hypersonic development and production,” said Eileen P. Drake, CEO and President of Aerojet Rocketdyne. “By applying decades of advanced research and development, together with engineering know-how and innovative manufacturing and materials, our products optimize performance while dramatically reducing costs and development time.”

Aerojet Rocketdyne’s AM initiatives

Headquartered in California, Aerojet Rocketdyne manufactures advanced propulsion and energetics systems for defense agencies and firms based in both the US and abroad. In order to fulfill customer demand, ranging from that for strategic missile systems to liquid or solid-fuelled engines, the company often turns to 3D printing, and there are several examples of when it has done so to-date.

As long ago as 2017, Aerojet Rocketdyne announced the successful hot-fire testing of a 3D printed thrust chamber for its RL-10 rocket engine, before achieving the same with its 3D printed AR1 propulsion system. That same year, the firm was also contracted by DARPA alongside Boeing to design a new experimental hypersonic spaceplane for launching satellites, though this has since been scrapped.

Since then, Aerojet Rocketdyne has bought 3DMT, in a move that boosted its manufacturing capabilities, with its acquisition believed at one time to have had one of the world’s largest metal 3D printing facilities. Fast forward to this month, and the company has unveiled an optimized 3D printed quad thruster as well, showing that its efforts to harness the technology’s potential remain alive and kicking.

Advancing Western defense capabilities

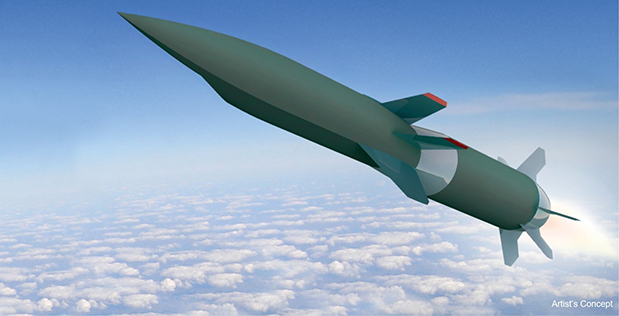

Led by DARPA and the USAF, the Hypersonic Air-breathing Weapon Concept (HAWC) program is focused specifically on creating missiles capable of hitting speeds north of Mach 5, that can be fired more rapidly and from a greater distance than before.

Thus far, the project has been built around three key pillars: feasibility, effectiveness, and affordability. This approach has seen the initiative’s participants pour a considerable amount of effort into identifying optimized vehicle configurations and approaches to thermal stress management, but they’ve also sought to come up with a new propulsion system.

To meet this need, DARPA and the USAF has turned to Aerojet Rocketdyne, which in turn, has created a scramjet engine that’s said to offer better aerothermal performance and scalability than its predecessors. When used in a recent flight test to power a HAWC vehicle prototype, the second to come from the program, the system is said to have allowed it to travel at Mach 5 or higher for over 300 miles.

Capable of flying at altitudes of 65,000 feet or higher, the vehicle is also understood to be ‘air-breathing,’ in that it utilizes air captured from the atmosphere to achieve sustained propulsion. As such, air breathing missiles have the potential speed and maneuverability to evade ground defense systems, while the kinetic energy they generate enables them to destroy targets without using high-explosives.

The vehicle’s flight test comes at a time when the US is seeking to bolster its defensive capabilities amid Russia’s war in Ukraine, and follows the unveiling of new AUKUS plans for hypersonic R&D. Given that Russia itself is also using 3D printing to upgrade MiG-31 fighters, furthering the reach of its own hypersonic payloads, the development comes at an opportune moment for the US and its allies.

“This Lockheed Martin HAWC flight test successfully demonstrated a second design that will allow our warfighters to competitively select the right capabilities to dominate the battlefield,” added Andrew “Tippy” Knoedler, HAWC program manager in DARPA’s Tactical Technology Office. “These achievements increase the level of technical maturity for transitioning HAWC to a service program of record.”

“We are still analyzing flight test data, but are confident that we will provide the USAF and Navy with excellent options to diversify the technology available for their future missions.”

3D printing in hypersonic flight

As Western countries ramp up their defensive spending in response to Russian aggression, many are beginning to focus on hypersonic flight-related research, in which 3D printing is playing a pivotal role. Over in Australia, Hypersonix Launch Systems has been awarded $2.95 million by the government to fund the R&D of a hydrogen-powered UAV, which is set to be built with 3D printing ‘where possible.’

In the US, meanwhile, America Makes has also poured funding into related projects, last month backing Boeing, RPM Innovations and Hexagon’s plans to develop mach-speed flight capable 3D printed parts. Specifically, as part of the project, the team aims to come up with a way of overcoming the variances in geometry within certain 3D printed components, which exclude them from high-speed applications.

Additionally, even before Russia’s full-scale assault, DARPA has long-expressed its willingness to deploy the technology at a greater scale. In September 2020, for instance, the agency commissioned a study into expediting hypersonic missile production, in which it detailed plans for a Hypersonic Production Accelerator Facility designed to house 3D printers among other advanced technologies.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows concept art of the flight-tested HAWC rocket. Image via DARPA.