US propulsion system manufacturer Aerojet Rocketdyne has optimized a key component of its Reaction Control System (RCS) quad thruster using additive manufacturing and nTopology’s engineering software.

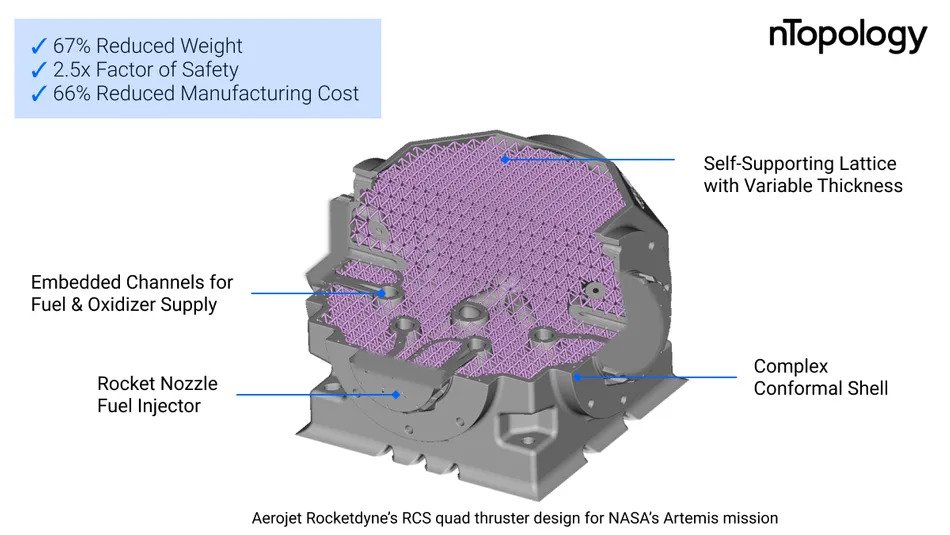

Aerojet Rocketdyne’s new space engine part is now 67 percent lighter while also reducing the overall production cost of the thruster by 66 percent to enable faster and more sustainable lunar exploration.

“If we leverage the advantages that we made over the last decade in engineering software and manufacturing hardware, we can build critical subsystems at fractions of the traditional cost while improving on the performance of heritage designs,” said James Horton, Mission Architect at Aerojet Rocketdyne.

Aerojet Rocketdyne and 3D printing

Aerojet Rocketdyne has been working on integrating 3D printing into the production process of its rocket engines, missile and tactical defense systems for more than two decades. In 2017, the firm renewed its commitment to using Sigma Labs’ PrintRite3D software, and also integrated a 3D printed preburner into its AR1 rocket engine which was later successfully hot-fire tested.

More recently, Aerojet Rocketdyne incorporated the 3D printing, CNC machining, and MIM capabilities of 3D Material Technologies into its portfolio. The firm has been using its capabilities to make critical parts for the RS-25 engine and has also received a $1.79 billion contract to create 18 of the systems for NASA’s ‘SLS project’.

Last year, the company announced an upgraded version of its RL10 rocket engine has passed NASA’s hot-fire testing procedures, and later completed a major expansion of its LA facility in order to support the SLS project.

Optimizing rocket engine components

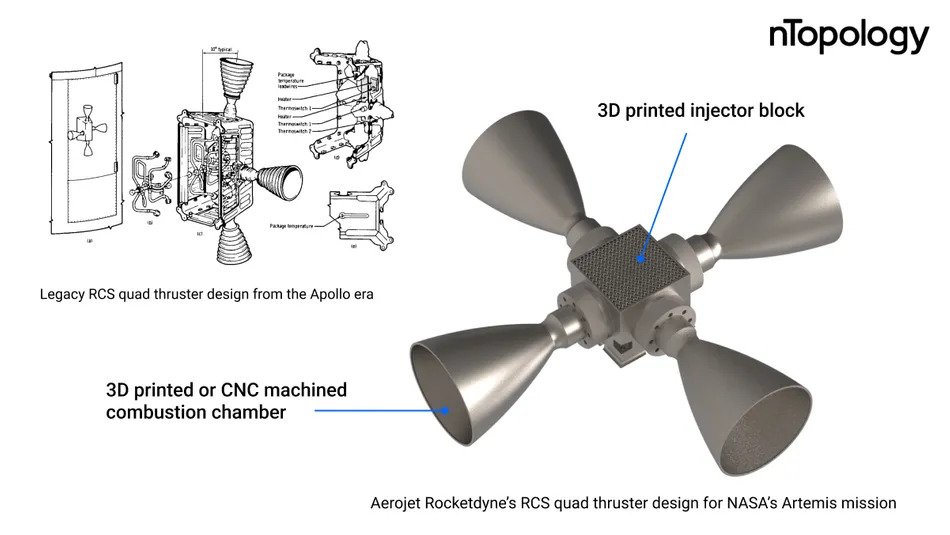

As part of its work with NASA, Aerojet Rocketdyne is redesigning legacy systems from the Apollo-era space program by developing the propulsion system for the Orion Spacecraft and Space Launch System for NASA’s Artemis program.

The firm has been working to optimize the weight and cost of key components of the RCS system, which controls the altitude and orientation of the spacecraft and lunar lander when they are in flight. The system is comprised of four service modules placed around the spacecraft and lunar lander which each features four thrusters.

The quad thruster setup allows each one to fire independently in order to better control the spacecraft’s speed, pitch, and roll. As part of its Apollo program, NASA commissioned the manufacturing of more than 600 thrusters to support 12 human spaceflights, testing and qualification. Reducing the cost of the thrusters could substantially lessen the total cost of the Artemis program, and so Aerojet Rocketdyne looked to optimize the components with additive manufacturing and nTopology’s engineering software.

Horton and his team identified several opportunities for improvement within the thruster’s legacy design, and sought to reduce the number of components in order to streamline the complexity of the build. The team then used a shell and infill technique in order to ensure lightweighting of the parts through nTopology’s implicit modeling engine.

The software also allowed the team to make improvements to the part’s fatigue strength and alleviate stress concentrations. Additionally, the team made use of nTopology’s field-driven design to control key design parameters of the thrusters, such as lattice bream thickness, to further reduce the part’s weight.

The RCS thrusters were printed on a Velo3D Sapphire metal 3D printer in Titanium 6Al-4V, a typical material used for manufacturing bipropellant thrusters, and that has half the density of Inconel 718. The successful 3D printing of the part is the next step in Aerojet Rocketdyne’s efforts to develop an RCS module that is one fifth the mass and one half the size of conventionally manufactured alternatives, while also being one third of the cost to produce.

“I didn’t know if it was even possible to do this type of integration,” Horton added. “We have shown that this is a viable path to affordability by reducing part count and touch labor. I am looking forward to bringing this product into space.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews, and webinar replays.

Featured image shows the Reaction Control System quad thruster. Image via nTopology.