Dutch sustainable architecture company Aectual has used plastic collected along the coast of a Belgian beach to 3D print a unique range of mussel-shaped plant holders.

Developed alongside fellow architecture firm DUS Architects, and made from 100% recycled plastic, the shell-like planters were initially commissioned for magazine Sabato’s annual ‘Knokke’ design series. Now set to be produced on-demand, and sold as numbered limited edition pieces, Aectual says that the large-format furnishings are perfect for “bringing the natural beach feeling” into people’s homes.

“We have to get rid of the negative idea that plastic is a disposable product,” said Hans Vermeulen, Co-founder and CEO of Aectual. “It is also a raw material with which you can make beautiful things, with the new craft of 3D printing. We want to help make the highly-polluting construction world cleaner, and the world a little bit more beautiful. It all starts on a small scale with this planter.”

Aectual’s architectural ambitions

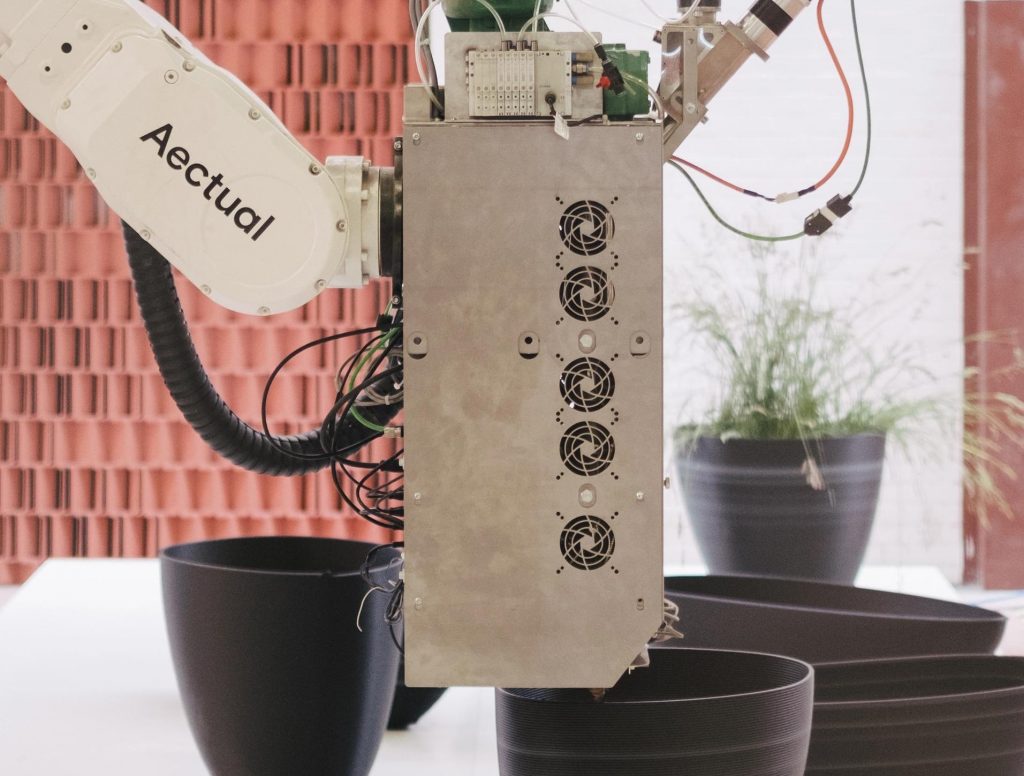

Founded in 2017, Aectual is a company dedicated to making customized architecture more sustainable and accessible for both designers and interior furnishing consumers. The firm’s manufacturing process is based around four robot arm-mounted 3D printers, which are capable of printing over a 500 sq. ft area with a range of 360°, unlocking the production of large customizable single-piece parts.

Compared to conventional construction methods, Aectual’s is also unique in that it’s compatible with a linseed-based bioplastic. Developed in collaboration with Henkel, the eco-friendly polymer can be recycled up to seven times, making it less wasteful than normal building materials, and the technology has now been deployed to create several large-scale proof-of-concept structures.

Since producing a sustainable 3D printed floor for Amsterdam’s Schiphol Airport in 2017, the company has used its technology to deliver a bespoke range of floors at the Italian Salone del Mobile, and during an in-depth interview, Vermeulen revealed that its recent growth has even seen it commissioned by household names like Nike, Burberry and Disney.

Over the last six months, Aectual has also attempted to better access the consumer market, launching the beta of an on-demand architectural 3D printing platform at CES 2021. The online design hub allows clients to customize and order panelling, fixtures and flooring to their door, in a model that the firm intends to roll-out at scale moving forwards.

“In five years’ time, we expect to be able to simply send the 3D file via the cloud, after which the cabinet or wall panel will be printed in America, Dubai or London,” said Vermeulen. “We also offer a digital library of existing designs on which designers can work further. As an open sharing space, Aectual [could] become the Spotify of architecture.”

The mussels from near Brussels

Built at the request of Sabato as part of its eco-friendly design series, Aectual’s 3D printed planters are designed to draw attention to the ongoing environmental problems caused by ocean waste. According to Sabato, each Belgian threw away an average of more than 30 kg of plastic during 2020, and earlier this year, a clean-up crew managed to collect a huge 120 kg of rubbish along the Knokke coast alone.

To do their bit for local sea life, volunteers from Aectual and Sabato therefore met to collect plastics such as bottles, caps and pieces of fishing net, before mixing them with household waste, recycling them into a 3D printable material, and blending in white pigment, to form the basis of the team’s mussel-shaped planters.

“[We chose] the mussel shell because scientific research shows that mussels contain an enormous amount of microplastic particles,” explained Martine de Wit, one of Aectual’s three Co-founders. “Also, a shell is actually 3D printed, but by nature. If you look closely, you can see that it has been built up layer-by-layer.”

Initially, Aectual made two prototypes, featuring low oval and high round shapes, with both containing the equivalent of 120 recycled plastic shampoo bottles. Given that each planter was individually printed and not mold casted, later specimens all looked slightly different from one another, but broadly measured 98 x 40 x 29 cm and 55 x 45 x 49 cm respectively, and sported a distinctly crustacean-like visage.

Following the project’s initial success, Aectual has agreed to print up to 500 of the planters which will be color-graded by hand, bear a unique signature and sold via Sabato’s website. The sustainable gardenware is being priced at a lofty €495 per piece, putting them well out of reach of the average Belgian, but Aectual’s Hedwig Heinsman says that the technology will only become cheaper as adoption grows.

“Now, 3D printed objects are indeed still relatively expensive, but that will change,” concluded Hedwig Heinsman, the third Co-founder of Aectual. “We are like Tesla. They first brought a very expensive racing car on the market. Each subsequent car was a little cheaper. This will also be the case with 3D printing.”

“We are the Tesla of the construction industry.”

3D printed home furnishings

Generally, designers produce 3D printed furniture in limited runs as a proof-of-concept, rather than with the aim of becoming construction’s equivalent of Tesla or Spotify. In May 2021, for instance, Viennese designer Philipp Aduatz worked with incremental3d to 3D print a collection of concrete furniture with unique gradient-dyed aesthetics.

In a more eco-friendly-focused initiative, Dutch design studio The New Raw has launched a zero-waste lab in Greece, through which locals can use household plastics to design and 3D print benches. Built as part of the wider Print Your City project, 3D printed chairs have since been showcased around Thessaloniki, to demonstrate the technology’s potential.

Elsewhere, with regards to building materials, scientists at the Massachusetts Institute of Technology (MIT) have developed lab-grown cells that could be used to 3D print sustainable furniture. By cultivating and tuning plant-based tissues, the team has been able to produce synthetic woods that, in future, hold the potential to ease global deforestation.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper-dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, de-briefs and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Aectual’s Co-founders alongside their 3D printed planters. Image via Aectual.