German sportswear brand Adidas has revealed what it describes as the “ultimate” 3D printed running shoe, the Futurecraft ‘STRUNG.’

The STRUNG sneakers, featuring the latest Futurecraft insoles produced by 3D printer manufacturer Carbon, have been created using an “industry-first” textile printing process. Adidas’ new data-oriented approach, combines software and robotics to precisely place each thread, allowing the footwear to be modelled to the exact contours of an individual runner’s foot.

“Futurecraft 3D is a prototype and a statement of intent. We have used a one-of-its-kind combination of process and material in an entirely new way,” said Eric Liedtke, Executive Board Member of Adidas AG. “Our 3D-printed midsole not only allows us to make a great running shoe, but also to use performance data to drive truly bespoke experiences, meeting the needs of any athlete.”

Adidas’ additive footwear aspirations

Adidas has been developing its Futurecraft line of sneakers for over five years. Initially working with 3D software developer Materialise, Adidas utilized advanced 3D foot scanning technology to get an exact measurement of a runner’s foot. At the time, the company hailed the “open-source partnership” as a landmark project between creatives and manufacturers.

Leveraging the experience it gained from working with Materialise, Adidas collaborated with environmental group Parley to create its ‘Ultraboost Parley’ shoes. The trainers were made from 95 percent dredged plastic waste, making it a very eco-friendly piece of footwear, but by then, Adidas had already begun to focus on its upcoming Futurecraft line of products.

The first Futurecraft running shoe, the 4D, was created by Carbon, and utilizing its Digital Light Synthesis (DLS) 3D printing technology, the firm managed to reduce its production time from 90 to just 20 minutes. Although the resulting midsole proved capable of taking the movement, stability, and comfort needs of the wearer into account, it had not yet been integrated into a full piece of footwear.

It wasn’t until January 2018 that the first fully-formed pair of 4D sneakers became available, but at an eye-watering price of $20,000. The ebay seller in question had competition from another listing on Grailed, which advertised a size 5.5 pair for a more reasonable $3,000, but the shoes have remained an exclusive and pricey commodity.

Since then, Adidas has gone on to collaborate with fashion brand Stella McCartney to develop its AlphaEdge 4D silhouette trainers, and Japanese designer Yohji Yamamoto, to produce fashionable Y-3 footwear. Now, having revealed its latest Futurecraft innovation, Adidas has taken a sportier approach, and returned to the idea of producing advanced additive running shoes.

Adidas’ Futurecraft STRUNG footwear

Adidas has collaborated with both Carbon and Materialise in its Futurecraft project as a means of designing a running shoe that can provide each individual athlete with the best possible running experience. In order to achieve this, Adidas has developed a new proprietary “STRUNG” process, which blends athlete data, 3D printing and robotics into a unique combination that weaves each thread for optimal performance.

The structure of the STRUNG was developed using Materialise 3-matic data optimization software, which allowed the midsole to be designed with flexibility, but without compromising its rigidity or strength. Data-mapping before production also enabled Adidas’ designers to test different structures before fabrication, and create a single composite with specific performance zones and properties.

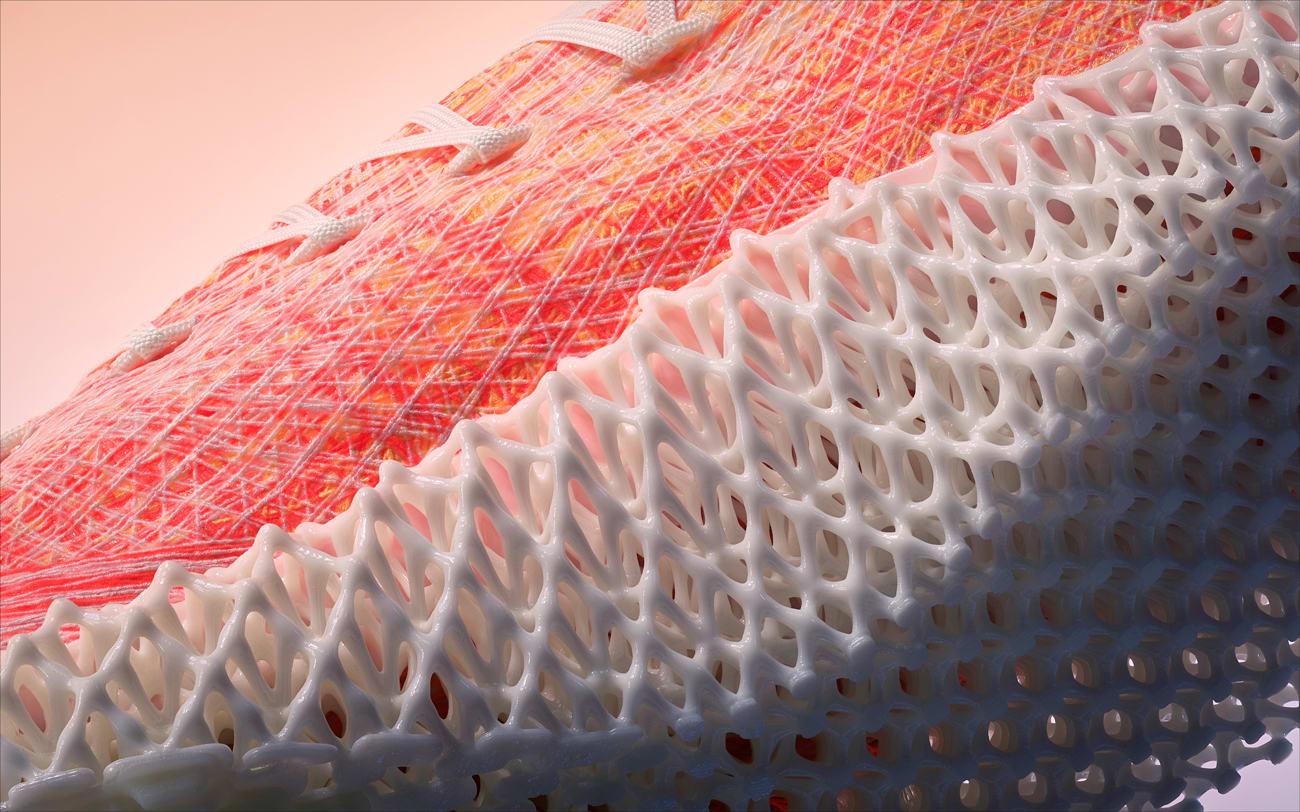

The resulting proof-of-concept sneaker features a lightweight lattice upper that’s precisely fitted for support, flex, and breathability, forming a “cocoon” around the runner’s foot. Using a data-driven approach also allowed materials to be deployed to optimize specific areas of the shoe. For instance, stronger red threads were used to provide grip in the heel, while its softer yellow threads offer users a greater deal of flexibility in the forefoot.

“We like to talk about our products ‘silently serving’ the athlete and, in this case, we’re getting more out of every thread so they can focus on nothing but their sport.”

The company’s latest running shoes are based on the Futurecraft Loop technology it unveiled last year, which uses fully-reusable thermoplastic polyurethane (TPU) materials, and no adhesives to hold sneakers together. Consequently, the additive footwear creates almost no-waste, lending it strong eco-friendly credentials as well as performance benefits.

Adidas isn’t marketing its latest 3D printed running shoe as a sustainable option though, in fact the STRUNG has been designed to cater for the needs of road runners. The lightweight prototype weighs just 220g (7.7oz), and Adidas’ own motion-capture tests were based on fast, short-distance sprints, indicating its intentions for its STRUNG line of shoes.

At present, the STRUNG is just a prototype, but Adidas is aiming to develop a new range of STRUNG trainers for different sports and runner profiles in future, with a potential launch slated for early 2022.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows concept art of Adidas’ STRUNG 3D printed trainer. Image via Adidas.