French industrial 3D printer provider AddUp and the Industrial Technical Center for Plastics and Composites (IPC) have established the ADDILYS platform to upgrade additive manufacturing for tooling applications.

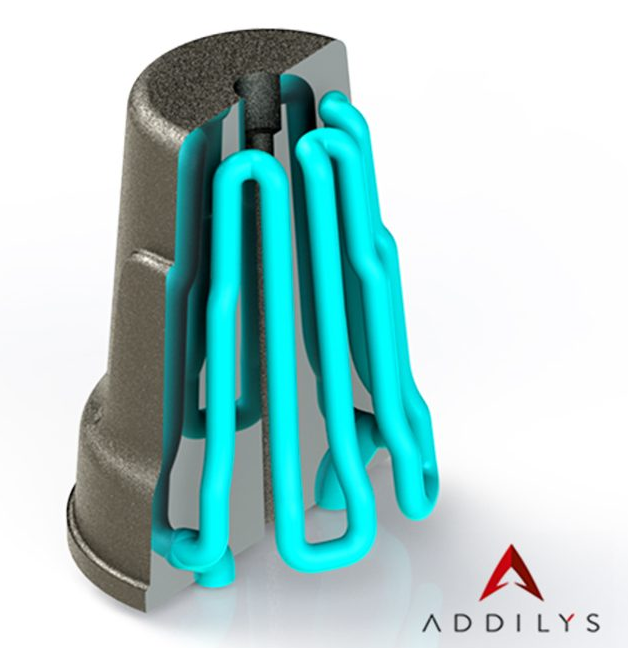

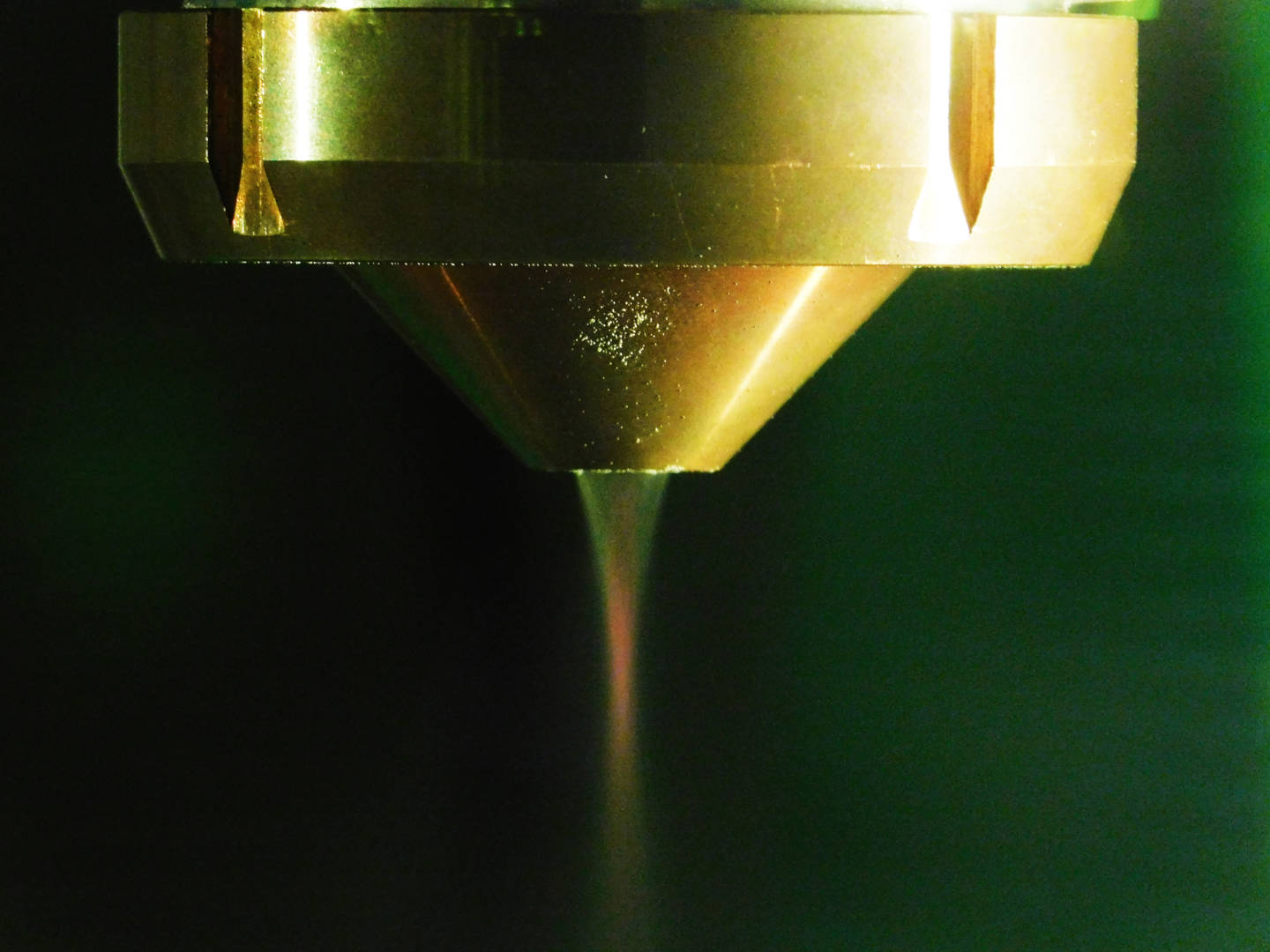

With ADDILYS, the partners will provide manufacturers with solutions and advice to deploy thermal solutions through the use of conformal cooling, enabled by metal 3D printing. This new entity will be based in the Auvergne Rhône-Alpes region, in proximity to AddUp and IPC.

“ADDILYS is THE trade response for plastics processing and tooling users,” said David Muller, CEO of ADDILYS.

“Combining 3D printing skills with the expertise of trade users (plastics processing, etc.) the company offers an optimum response for technical solutions that bring benefits in the quickest and most efficient way while offering ad-hoc support in order to improve operational productivity.”

The ADDILYS platform

AddUp commenced in 2016 from Fives-Michelin Additive Solutions, a joint venture providing unique metal additive manufacturing services. In 2018, the company went on to acquire BeAM, a manufacturer of directed energy deposition (DED) machines, and a majority stake in Poly-Shape, a French additive manufacturing service provider.

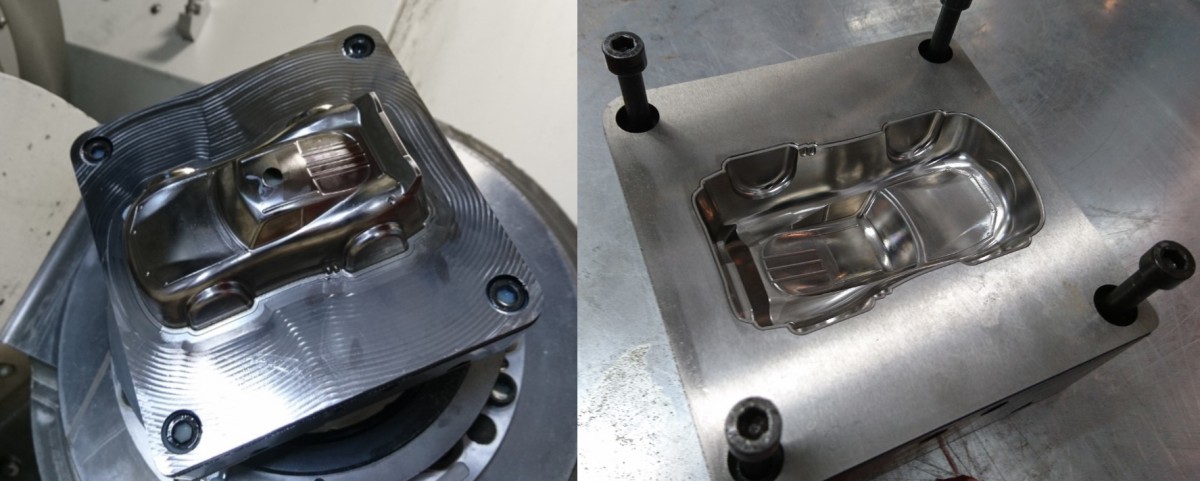

Moreover, IPC specializes in plastic and composite innovation. Earlier this year, it partnered with Smoby, and Materialise, to create miniature versions of the Lightning McQueen car with metal 3D printed molds.

Together, AddUp and IPC will combine its capabilities through a hub strategy tailored to sectors such as aeronautics and energy, to assess its customers’ products, process skills in additive manufacturing, and high-performance machinery. In doing so, customized thermal solutions and 3D printed molds will be created to enable plastics processors, improving cycle times and productivity.

“The IPC Technical Centre was created a few years ago by plastics processing manufacturers who were seeking to boost innovation and improve their companies’ competitive edge,” stated Etienne Béchet de Balan, IPC President.

“This unusual partnership between a research centre and a manufacturer, ADDUP, the emerging leader in additive manufacturing, is a real opportunity to harness each organization’s skills and the R&D advances gained over the last few years to the benefit of sector manufacturers.”

Adding value with additive manufacturing

Presently, IPC and AddUp, through ADDILYS, are offering consultation to support projects that require personalized tooling. Vincent Ferreiro, Director General at AddUp, added, “As pioneers in the development of 3D printing solutions for manufacturing, and thanks to the experience gained from our shareholders, Fives, and Michelin, we are convinced that creating this platform with IPC will enable manufacturing industry actors that use molds to access an innovative service offering that is able to add enormous value.”

For updates on this partnership, and other business news subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Seeking a new career move? Search and post 3D Printing Jobs now through our specialist service.

Featured image shows a 3D printed cooling channel on a part. Image via AddUp.