North Dakota State University’s (NDSU) Jeremy Straub has published two recent papers discussing the cyber security threat to 3D printers. The two papers present the growing threat of cyber attacks to 3D printing and possible solutions to the problem.

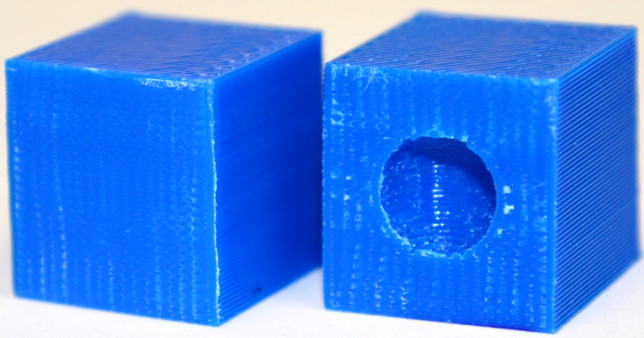

Published by SPIE, ‘Identifying positioning-based attacks against 3D printed objects and the 3D printing process’ was discussed at the Pattern Recognition and Tracking conference. In this paper Straub, an Assistant Professor in the Department of Computer Science at NDSU, presents how malicious alteration of 3D printed objects is problematic.

A further paper, ‘A combined system for 3D printing cybersecurity’, is also published by SPIE, Straub presents a method for counteracting cyber attacks on a 3D printer using a “light sensing-based verification system.”

Growing cyber security threats

As 3D printing continues to find both industrial and consumer applications, the threat of altered or defected objects subsequently heightens. Straub also believes that for 3D printing to continue to be adopted, the issue of cyber security needs to be addressed.

This hazard is exacerbated when considering the industrial use of additive manufacturing, since the stakes are higher when functional parts are defective. While testing of finished printed parts is one way to combat this issue, it is time consuming and many large companies are looking towards other qualification techniques.

Straub explains this will especially effect consumers as they are unlikely to have access to advanced preventative measures and proposes an image monitoring system that works in real-time in a 3D printer to detect alterations that suggest defective prints.

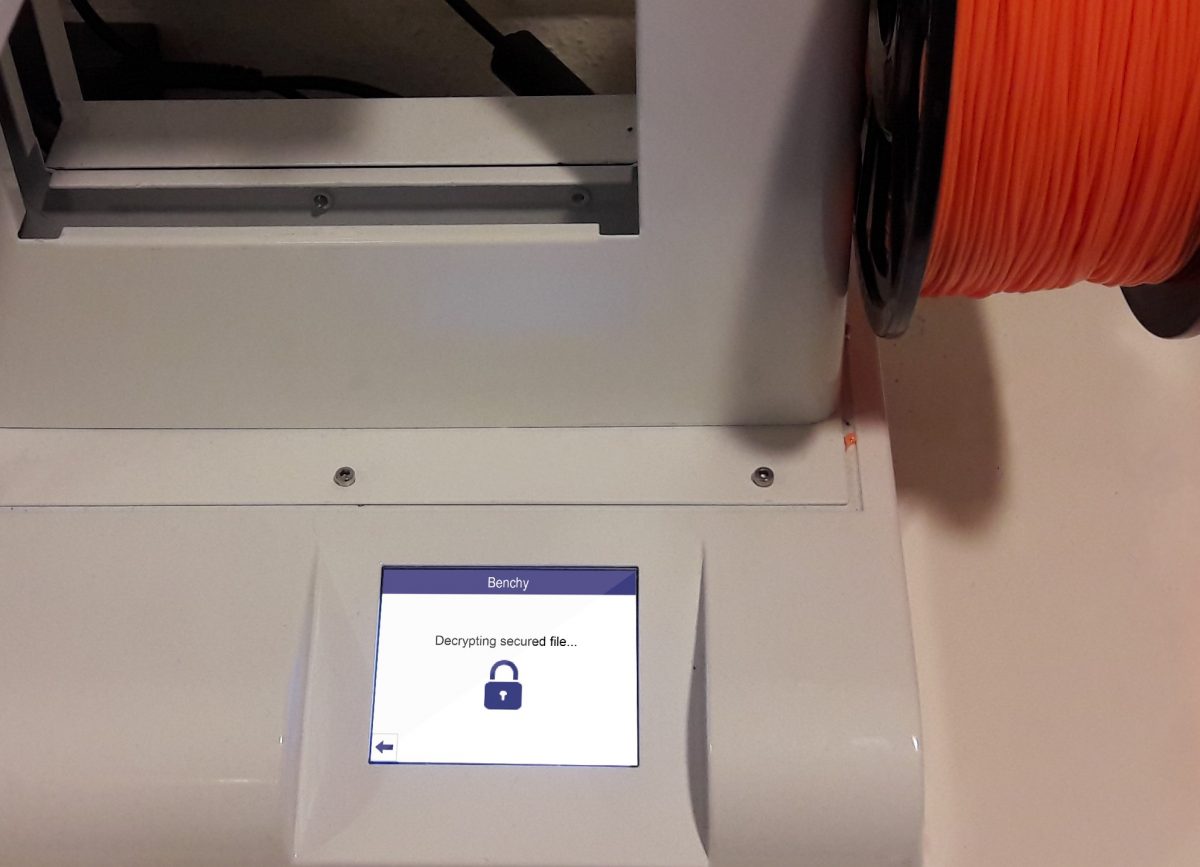

Current cyber security solutions for 3D printers include firewalls to stop access to 3D printers or the encryption of 3D files.

Danish company Create it REAL has developed a platform for encrypting and decrypting 3D files onboard a 3D printer. The main aim of the encryption process is IP protection but it could also mitigate malicious attacks by preventing file alteration.

Proposed security system

To combat the problem, Straub proposes a monitoring process that could identify if and when an attack has occurred. The system is implemented in real-time as the 3D printer is operating and could allow a print job to be aborted. The system described in the paper uses five cameras to monitor the 3D printer and compare the object printing in reference to its expected shape. By doing so, Straub hopes to identify if an object is misaligned on the printer bed or altered.

A real-time monitoring system has similarly been explored by GE as it is set to create the world’s largest powder based 3D printer. GE’s recently published patents suggest the company is working with in-situ monitoring to certify parts and the process may have potential to detect threats in Straub’s proposed way.

For all the latest on 3D printing research, subscribe to the most widely read newsletter in the 3D printing industry, follow us on twitter and like us on Facebook.

Featured image shows Figure 3 from Straub’s paper of the monitoring process inside a Makerbot. Image via SPIE.