Engineering with robotics and electronics has gained a lot of traction, thanks to the 3D printing revolution, but one facet that the technology has yet to greatly improve is the ability to efficiently print in multiple different materials at once. Most approaches to 3D printing with mixed materials have been passive processes, often limited to mixing thinner materials with lower viscosities and leaving thicker printing materials to mingle on their own. A new development from the Harvard lab of Jennifer Lewis, also the CEO of Voxel8, has managed to solve this issue by creating an active mixing multimaterial printhead.

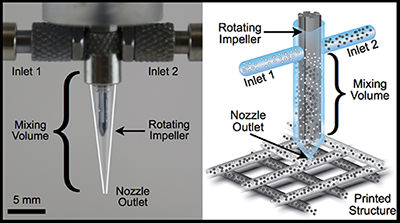

When it comes to mixing materials with 3D printheads, the difference between a passive and active mixing model is quite simple. the passive approach works by combining disparate fluid materials into a single channel where they are mixed together before being dispatched from the printhead. The active mixing method used by Lewis and her team on the other hand, is conducted with a rotating microscale nozzle that is able to efficiently mix more complex and higher viscosity materials. With this new type of multimaterial printhead, Lewis has made it possible to 3D print more complex and gradient architectures, thus allowing for better quality manufacturing of soft robotics, wearables, and other electronic items.

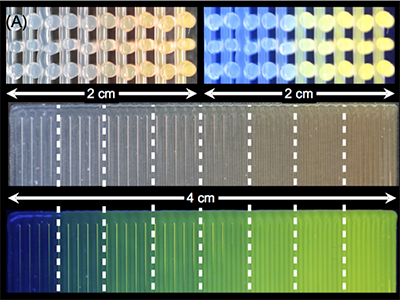

Lewis and her team tested their printhead in a multitude of different ways, seemingly proving that they have discovered the next step in printing with mixed materials. They used the multimaterial printhead to flawlessly compose soft and rigid regions of gradient architectures with silicone rubber material, which holds a lot of potential use for flexible electronics and robotics. They also proved that their printhead could be used to mix conductive and resistive inks together, allowing for the construction of electric circuitry within 3D printed objects.

They haven’t just stopped at this multimaterial printhead either, Lewis and her team also created another printhead that can quickly and reliably switch between different materials and disperse through a single nozzle. This particular printhead was made to solve the issue of defective structures that often occur during the long pauses that usually take place when standard printheads attempt to switch between different materials.

In a recent interview with 3DPI, Dr. Lewis discussed the possibilities of the next generation of her company’s electronics 3D printer, saying that the subsequent version of the Voxel8 multi-material system would likely be able to 3D print elastic materials. While not many details were disclosed, the close relationship between Dr. Lewis’s lab at Harvard and her work at Voxel8 is a close one, leaving us to speculate whether this new multi-material printhead might find its way from the lab into the startup sometime in the future.