The latest developments in digital fabrication for construction were discussed this week at the American Association for the Advancement of Science (AAAS) 2017 Annual Meeting in Boston. At the meeting, digital fabrication techniques of the future were discussed including new 3D printing materials.

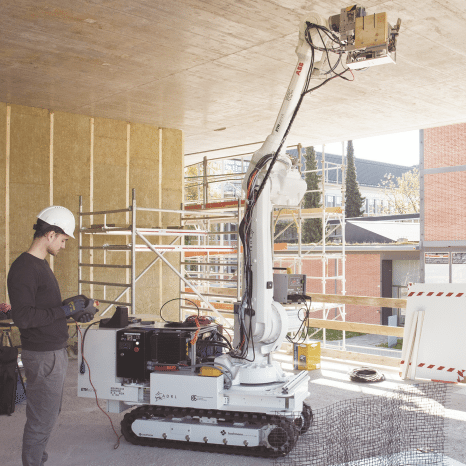

Present in Boston were researchers from ETH Zurich who are exploring the use of robots to create mesh structures in concrete construction. The ETH Zurich research group received the Swiss Technology Award 2016 for their In situ Fabricator.

Other attendees included Ronald Rael, Associate Professor for Architecture at University of California, Berkeley. Rael gave a presentation on materials for 3D printed construction. Such materials will alleviate issues of scaling and higher costs when 3D printing on such a larger scale.

3D printed construction

Using 3D printing to construct structures provides a number of benefits, including mass customization possibilities. Furthermore, the technique also provides a cost-effective way of producing large-scale structures. The group of researchers present at the meeting view digital fabrication techniques, such as 3D printing, as the future of construction work. Advances in 3D printing and 3D designing in recent years have also showcased the possibilities of the technology.

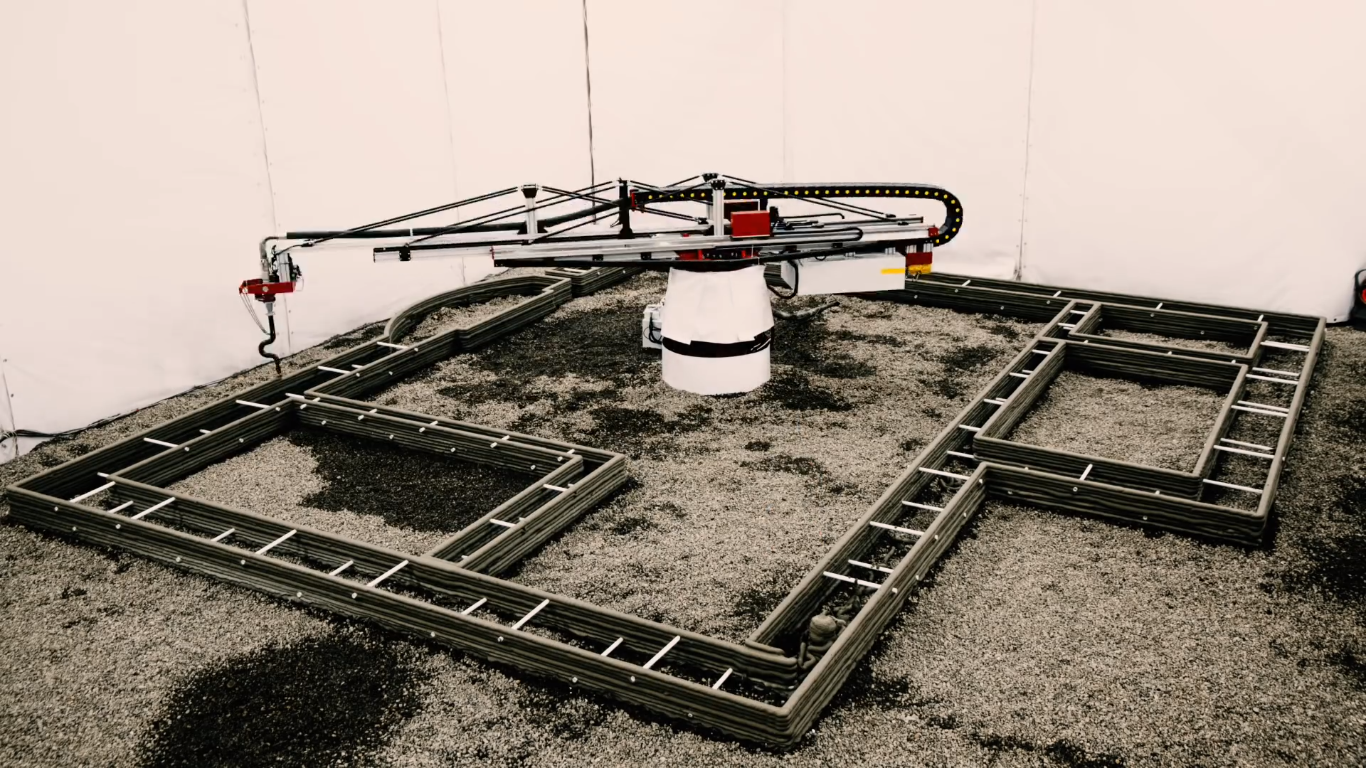

The In situ fabricator, developed at ETH Zurich is a robot capable of creating complex mesh structures to be used as framework for concrete. Concrete 3D printing is currently undertaken by several enterprises, including Apis Cor and CyBe. Russian company, Apis Cor has created a concrete 3D printer capable of constructing a small-scale house. The machine sits in the middle of the structure and builds the house up around it. While Dutch construction company, CyBe has created a concrete 3D printer on wheel-tracks. This enables the 3D printer to roam about the difficult terrain of a construction site.

3D printing sustainable materials

The possibility of using robots for construction was also evaluated by Italian engineer, Enrico Dini. As the creator of one of the world’s first construction 3D printers, Dini envisages a future whereby buildings will be 3D printed using local materials. This means buildings in Egypt would 3D print sand and building on the moon would involve lunar dust aka regolith. Ronald Rael, during the AAAS meeting also expressed the desire to use local sustainable materials for 3D printing.

Sign up to our newsletter for the latest in 3D printing news.

Featured image shows a concrete model created using digitally fabricated mesh mould. Image via Gramazio Kohler Research, ETH Zurich.