In its pursuit of acceleration for the Fourth Industrial Revolution, Global information technology company HP has opened a 150,000 sq ft 3D Printing and Digital Manufacturing Center of Excellence in Barcelona, Spain.

3D Printing Industry was present at the facility’s inauguration yesterday which highlighted a plethora of new alliances, industrial use cases and technological developments for HP within the additive manufacturing sector.

“Playing in the prototyping business and manufacturing business is totally different,” explained Christoph Schell, President 3D Printing and Digital Manufacturing, HP.

“We’re looking for customers who will use HP 3D printing technology to disrupt a business model and this center, its experts, and its resources will help facilitate that for this new era of manufacturing.”

Doubling-down additive manufacturing for production

Spanning across more than three acres, the HP 3D Printing and Digital Manufacturing Center of Excellence is part of HP’s industrial 3D printing portfolio. Further, the site will act as an environment for HP customers and partners to optimize and integrate additive manufacturing production processes.

Currently the facility hosts an HP Jet Fusion laboratory dedicated to its latest line of 3D printers, the 5200 series, as well as a Metal Jet lab to foster the adoption of industrial 3D printing and new material development.

Ramon Pastor, VP & General Manager, HP 3D Printing Business, stated, “This center is helping us to double down on additive manufacturing processes. We have a mission that’s not so easy to complete – and this is the automation and optimization of AM; a market that has been looked at as a whole new entity within itself.”

Overcoming conventional quality standards

Corresponding to the release of the HP Jet Fusion 5200 series, both Pastor, Schell, and Rebecca Campbell, 3D Services Business Director at HP, emphasized the importance of collaboration with those experienced in additive manufacturing and others in the first stages of implementation. This is enabled through the HP Digital Manufacturing Network.

“We want education to be the main theme of our network,” said Campbell. “It will not be an aggregator or a marketplace for 3D printed parts, but a platform where engineers can learn about new technologies and understand what quality means above the conventional manufacturing sense.”

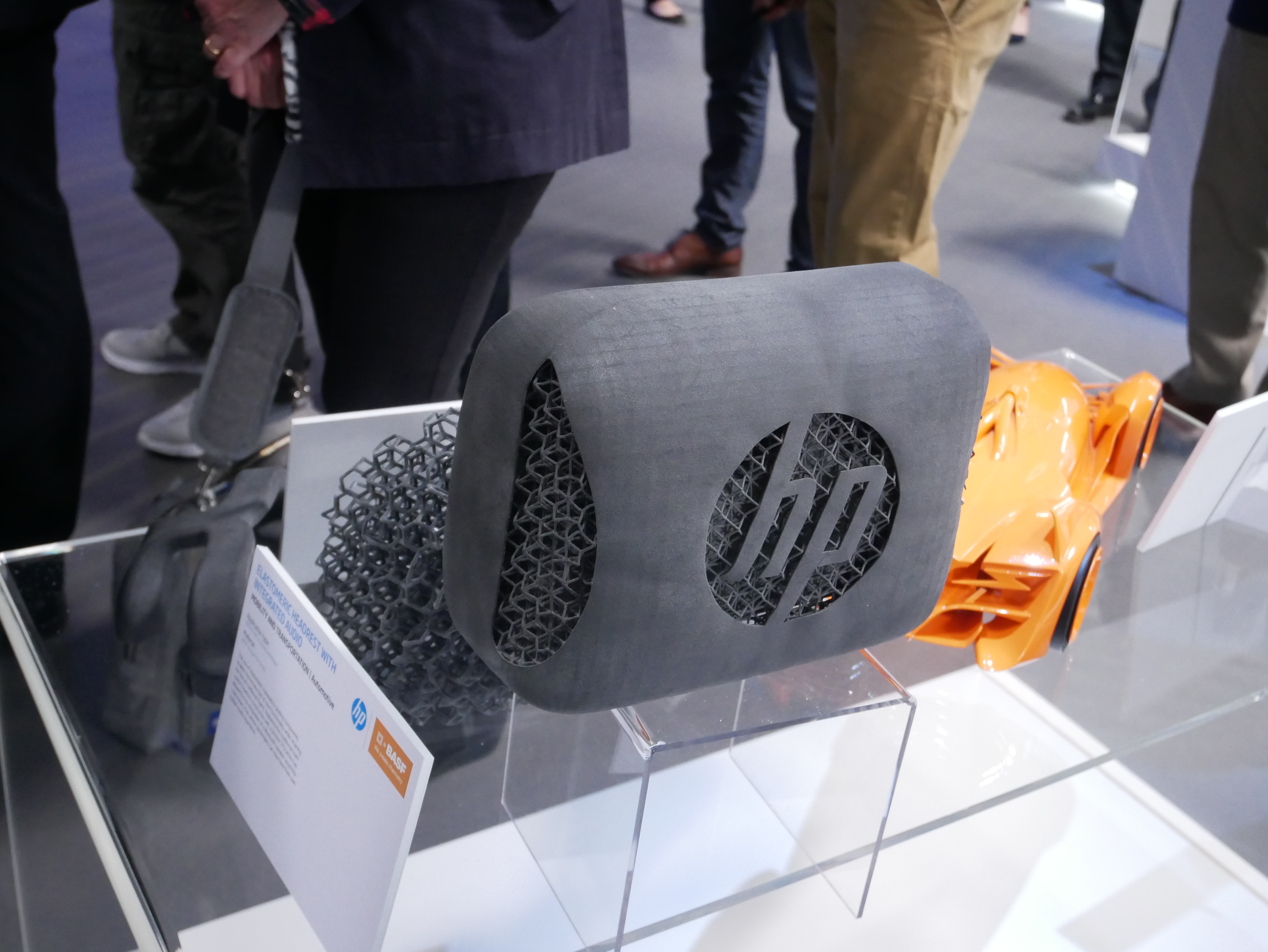

Siemens, Materialise, SmileDirectClub, and BASF are some of the partners included in the network who are sharing expertise in digitization, teledentistry, and materials to leverage both plastic and metal additive manufacturing processes. As a leading chemical producer, BASF has recently developed ULTRASINT TPU for the 5200 Series. The first end-use 3D printed TPU parts are included in the new HP Stitch digital textile printers.

This material is also being used to prototype new automotive applications, such as seating components as it improves on the comfort and flexibility of traditional foam. For example, an elastomeric headrest with an integrated Bluetooth speaker has been conceptualized with TPU lattice structures.

Mass production with Metal Jet

In addition to innovation with Multi Jet Dr. Tim Weber, Global Head, 3D Metals at HP, divulged some of the future efforts the Center of Excellence will execute to enable mass production with metal additive manufacturing.

“Our introductory HP Metal Jet system was introduced last year with a large bed size of 430 x 320 x 200 mm. This machine can produce stainless steel parts matching ASTM International standards at 50 times the capacity of conventional methods,” explained Dr. Weber.

“Currently, metal powders are being tested by our material scientists for the new HP Metal Jet system which will be introduced very soon. This could significantly disrupt our partners and customers in the aerospace and automotive sectors when it comes to mass and volume production. This includes GKN Aerospace and Volkswagen. ”

According to Dr. Weber, the new Metal Jet system is expected before 2020.

Keep up to date with the latest additive manufacturing news by subscribing to the 3D Printing Industry newsletter, following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the HP 3D Printing and Digital Manufacturing Center of Excellence. Photo via Vicens Gimenez/HP.