Up on seventh floor of the NYDesigns incubator, which is located in Long Island City, Queens, sits a relatively small 3D printing company focused on some big-time innovation. The startup, called BotFactory, was founded in July 2013 by Nicolas Vansnick, Carlos Ospina, and also Michael Knox, a professor from the NYU Polytechnic School of Engineering. Since then, BotFactory hosted a successful Kickstarter for their electronic circuit 3D printer, the Squink, which raised over $100,000 in crowdfunding. BotFactory hasn’t slowed down, in fact, just the other day, they were awarded with the Best Technical Development Manufacturing Award at the prestigious IDTechEx.

The other day, I had the opportunity to visit their office and sit down with JF Brandon, the VP of Sales and Marketing for BotFactory, we talked about their circuit fabrication technology, newly developed multilayering capabilities, and why the Squink is leagues ahead of other electronic desktop 3D printers. To start our conversation, Brandon discussed the hassle of manufacturing circuit boards in a traditional fashion, and how the Squink has set out to fix this dilemma.

“When you’re making electronics, you model it on a computer, you make the design layout a plant this component and that component, and you send it to a company in California or China or Europe, it’s never done locally, we’ve never heard of a local fabricator,” Brandon started. “When they build the board, you can’t just buy one, you usually have to buy a minimum order of ten, and that gets very expensive. It can be easily $600- $1,000, and it also take two or three weeks. So by the time the design is ready, you’ve sent it out, deal with delays, and when you finally get it back and you discover that you made a mistake.”

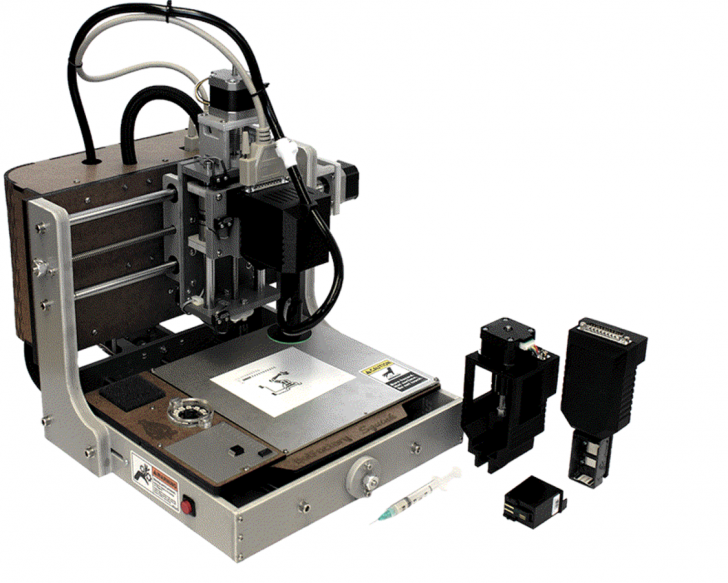

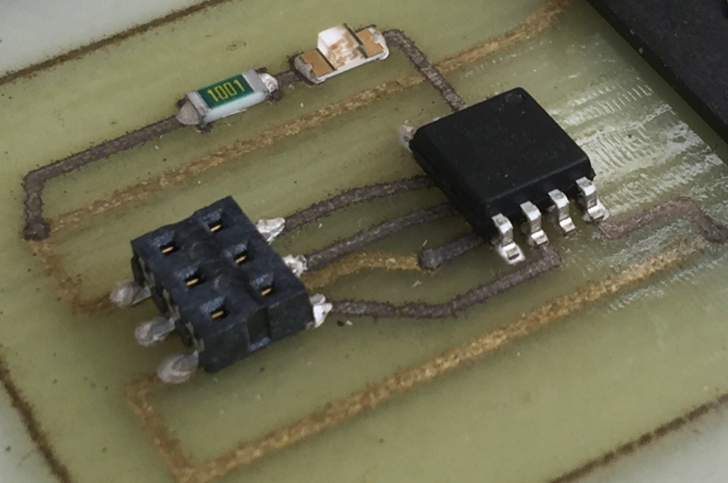

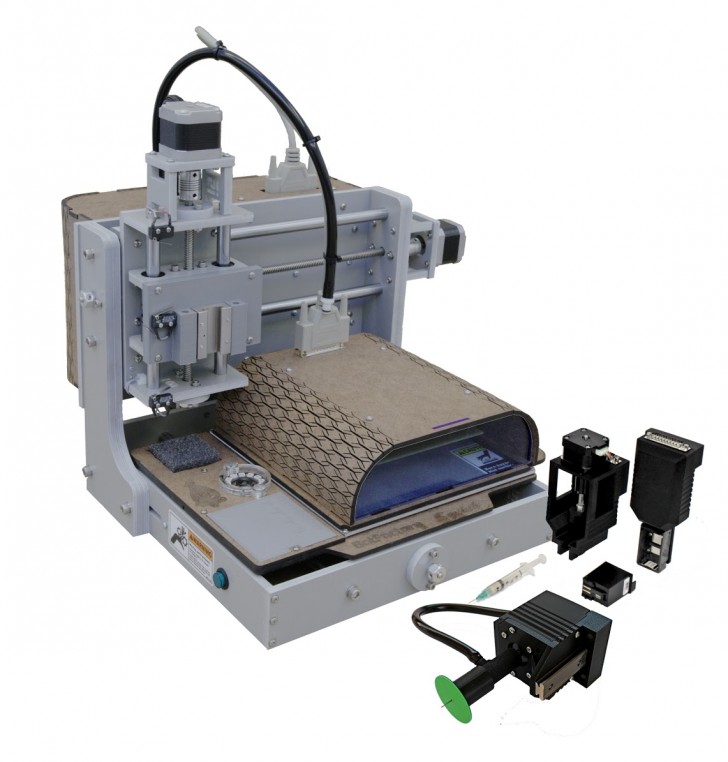

So, as you can see, fabricating electronics were previously a costly, time-consuming, and risky endeavor, but with the Squink, all of the aforementioned issues are obliterated, making circuit printing more affordable, faster, and easier to prototype. Considered to be a personal circuit factory, BotFactory’s desktop sized printer takes users through the entire process of fabricating circuit boards. Utilizing an inkjet printhead, the Squink prints circuit traces in a low resistivity conductive ink. The extruder toolhead is also capable of laying down solder paste and conductive glue, and perhaps most intriguingly, offers a Pick-and-Place toolhead to precisely place components onto the circuit traces. The printer is relatively expensive, but for BotFactory, a higher price point means high quality and efficient performance.

“A lot of people say, ‘hey this is an expensive machine’, it’s a $3,000 machine, that’s true,” Brandon said. “But, what we put into this machine is an incredible amount of effort into making the entire thing reliable, which is not an easy task. 3D printing has kind of come from an open source environment, which is great, we’ve had to teach ourselves everything regarding ink jetting technology. There’s an image recognition system on here to actually identify the components, and then orient and off set them correctly. That’s called pick and place, and it’s actually the industry standard for how you actually deposit and place components.”

So, who exactly was the Squink created for? Well, according to Brandon, BotFactory’s technology is applicable for almost any innovator, from the industrial level to consumer. “We’ve been shipping more and more machines to Fortune 500 companies, Ivy League colleges, small community colleges, small companies, hackers, hobbyist, you name it, we ship basically to anywhere in the Western world,” Brandon explained. “We’ve been going step by step and doing all of the things that a hardware company should do, like very carefully managing our inventory, every single item is logged and categorized, every sub-assembly has an instructions manual for how you build it. We’ve always tried to build a product that is extremely reliable, people don’t mind expense if they know they’re getting a reliable product. That’s why companies like LulzBot and Ultimaker are doing really well compared to lower end printer.”

Brandon went on to give examples of different ways their customers have utilized the Squink. “People buy this product for one specific project sometimes, we had one lady who bought one specifically to make light-up Lego blocks, we had one guy working at NASA with flexible electronics who said our machine is capable of doing what they need. There’s big companies who use it for testing very small items. We have people who are buying these to help teach their students the basics of PCB prototyping, or to create artistic work,” Brandon said. “While the road has been long and tough, we believe that fundamentally in the end were changing the way people look at electronics in the same way 3D printing is changing the way people look at physical objects.”

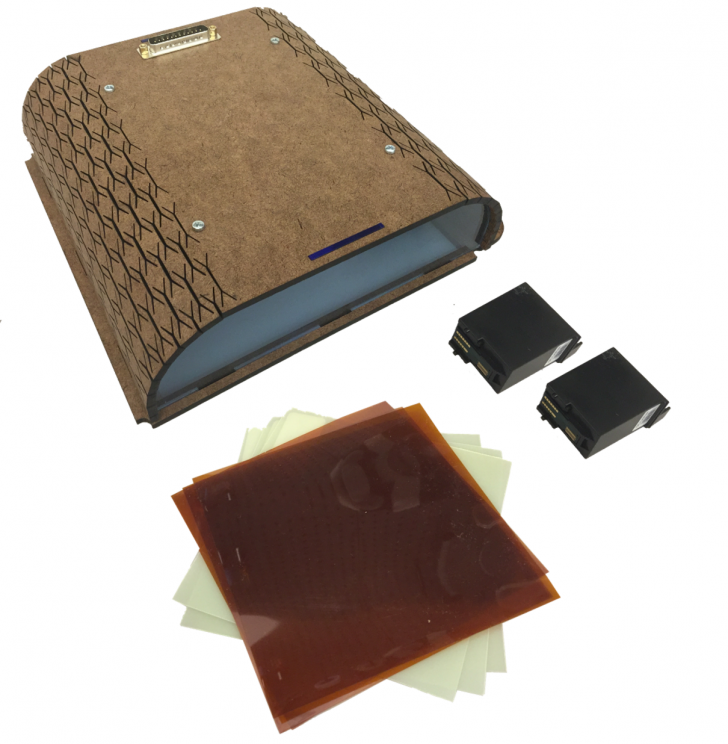

Although the Squink is a well-established and wholesome machine already, BotFactory is continually working towards improving their circuit printing system, and have just recently announced a breakthrough in multilayering conductive inks. Their newest development, called the “Multilayer Package” will include a new cartridge equipped with insulating ink and a curing lamp. The insulating ink is safely cured by the UV light, and allows Squink users to print insulating ink on top of the conductive traces or to print traces on top of an insulating layer.

“Generally speaking, multilayering is a capability everybody asks about, and multilayering essentially allows you to print traces on top of each other. For example, your typical iPhone might have anywhere from 10-40 different layers, the traces are going from component to component and passing by one another,” Brandon explained to me, prior to their recent announcement. “We will be releasing an ink that essentially allows you to do two layers, with the possibility for even more layers as the material and software get better. That basically means you can make flexible and/or stiff boards with multilayers, which is huge, it solves a lot of problems for people. They can now make smaller boards, they can make more complicated circuits, they can add more components. Essentially it will consist of an ink and a lamp that cures the material once it’s printed, then you print on top of that.”

For BotFactory, their goal is to continue leading the way for electronic 3D printing, continuing to be one of the only companies offering an all-in-one circuit board fabricator. The Squink is set to make circuit printing more accessible, reliable, and affordable, and with their new multilayering technology, looks to be setting themselves apart from the pack once again.

“No one has really managed to integrate the full package, I can give you a list of abut 30 different companies trying to do circuit printing in some case, and were the only guys that are offering a fully integrated solution, soldering, pick and place, circuit printing, stiff and flexible boards, heat curing right on the build platform, it’s the whole works. For $50,000 you can buy a machine to make pretty good boards, but for $3,000, you can just buy a Squink, and print the board for yourself right away,” Brandon finished.