As the adoption of professional low-cost and home-based 3D printing widens, so do the quantities of plastic used towards it. While these quantities still pale in comparison to the enormous plastic consumption of truly mass-manufactured products, in many ways, 3D printing is rapidly transforming the possibility of creating new products into a a reason to consume even more plastic.

Before that happens, the 3eco project, by studio TryeCo 2.0, wants to implement a serious program of plastic recycling aimed towards the production of high quality filaments. While TryeCo was one of the first design studios in Italy to seriously implement 3D printing technologies, this idea is not entirely new, as several projects are already in place that aim to do just that.

Recently, I had the opportunity to speak with the founders of Better Future Factory about their first commercially available recycled PET and ABS filaments. However, the 3eco project wants to take this approach to the next level by raising awareness among the general public about the necessity for a more differentiated recycling approach that separates not only plastics from other materials, but also different types of plastics.

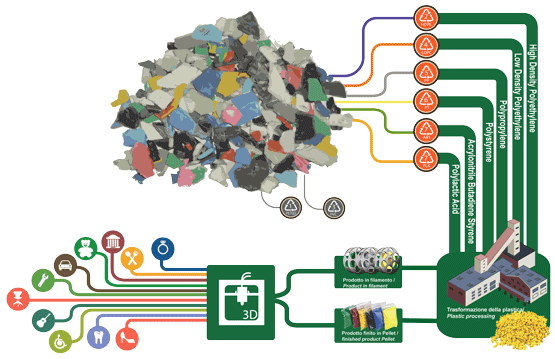

3eco’s recycled plastics are available either as pellets or as extruded filament: both come with cardboard packaging and spools. The available materials already include high- and low-density polyethylene (HDPE and LDPE), polypropylene (PP), polystyrene (HIPS), as well as ABS and PLA. The team working on the 3eco project includes Matteo Fabbri for the administration and research, Roberto Meschini for R&D and brand management, and Federico Balboni for the marketing activities.

Leveraging a partner that has been active for over 50 years in plastics recycling, 3eco wants to begin targeting urban waste, where only 3% of the 240 million tons of plastic consumed yearly is recycled. The next step would be the recycling of plastics from the soil, where it is estimated that as much as 1 billion tons of plastic waste has been accumulating since the 1950’s. Finally, 3eco would target the oceans, and the over 5 million plastic objects that are thrown away at sea every single day.

Plastic and filament manufacturers are beginning to come to grips with one unalienable fact: as the demand for 3D printers and 3D printed parts increases, we are faced with a choice. Either increase the global use of new plastics, thus increasing pollution and the presence of C02 in the environment, or develop ways to produce high quality filaments and pellets from recycled plastic, thus effectively reducing the need for new plastic and the pollution that inevitably would ensue. To me, this does not seem like a choice at all.