3Deus Dynamics, a developer of 3D printed silicone medical devices, is developing a new hybrid process that combines 3D printing and injection molding to produce anatomical models for the medical sector.

Called Dynamic Molding, the process was originally developed by the company’s founders at the 3d.FAB platform at Lyon 1 University, and is the subject of two patents. As part of its development under 3Deus Dynamics, the technology has now been successfully deployed to create a life-sized patient-specific 3D model of a complex arterial disease for use in the planning and simulation of complex vascular surgeries.

3D printing anatomical models

Producing realistic and accurate representations of the morphology of the human body is vital in the teaching of anatomical knowledge, and this is where the benefits of 3D printing technologies can play a key role.

For some years now, 3D printing has been leveraged to produce precise, patient-specific 3D printed anatomical models with higher degrees of color fidelity that can save several hours in surgical planning time. As additive manufacturing technologies mature, a growing number of 3D printing companies are therefore gaining ISO certification and FDA clearance for their 3D printed models.

As a result, point-of-care 3D printed anatomic modeling services are becoming more popular, with the likes of Stratasys and Ricoh USA partnering to deliver 3D printed models to healthcare facilities, and Fast Radius and Axial3D offering a new ‘DICOM-to-Print’ service for hospitals across the US.

The Dynamic Molding printing process

3Deus Dynamics was established in 2020 by Edwin-Joffrey Courtial, Christophe Marquette, and Julien Barthès, with the goal of developing a breakthrough printing technology for the production of class III silicone medical devices.

The firm’s multi-patented Dynamic Molding technology is a hybrid process that sits at the crossroads of 3D printing and injection molding. While the process is compatible with all common injectable materials, it is particularly suited to working with specialty silicones.

The process works by using the flow properties of fluid silicones and granular materials such as glass beads to manufacture objects with complex geometrical characteristics. The fluid silicones are deposited by a micro-doser immersed in a granular medium which then forms a dynamic mold to support the material during printing.

The physical properties of the powder used supports the object during the printing phase and ‘self-repairs’ after each of the micro-doser’s movements. By overcoming gravity in this way, the process prevents the print from collapsing, which is a common problem when 3D printing flexible materials.

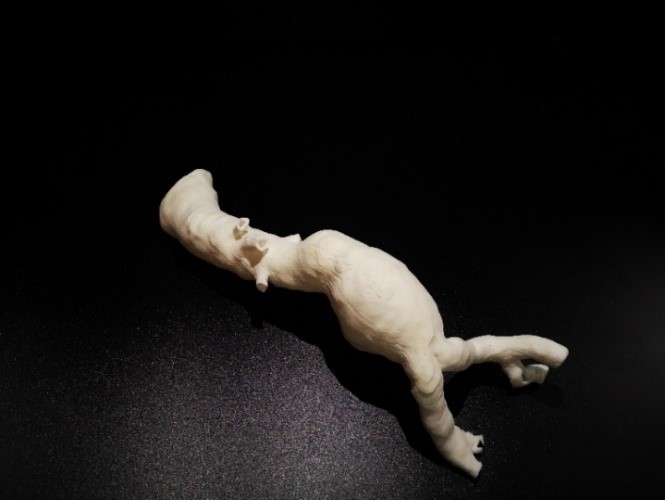

As a result, Dynamic Molding enables the production of durable physical and complex silicone replicas of complex organs, such as the heart, prostate, brain, kidney, and lung. In addition to their durability, the models replicate the texture and elasticity of native human tissues and can be cut, sutured, and infused with stents and implants without tearing.

The method is also capable of producing structures of varying rigidity in order to model pathological structures such as tumors within an organ.

Treating arterial disorders

3Deus Dynamic’s Dynamic Molding process has been successfully leveraged to produce patient-specific 3D printed anatomical models to aid the treatment of complex arterial disorders such as aneurysms. Producing accurate, realistic replicas of tissues and arterial pathologies allows for a better understanding and simulation of surgical procedures and the appropriate treatments required for particular patients.

The Dynamic Molding process was selected by the second largest hospital in France, the Hospices Civils de Lyon, in order to carry out a project led by vascular surgeon Patrick Feugier. The ImVasc3D project aimed to produce a patient-specific 3D model of a complex arterial disease to be treated by a minimally invasive procedure.

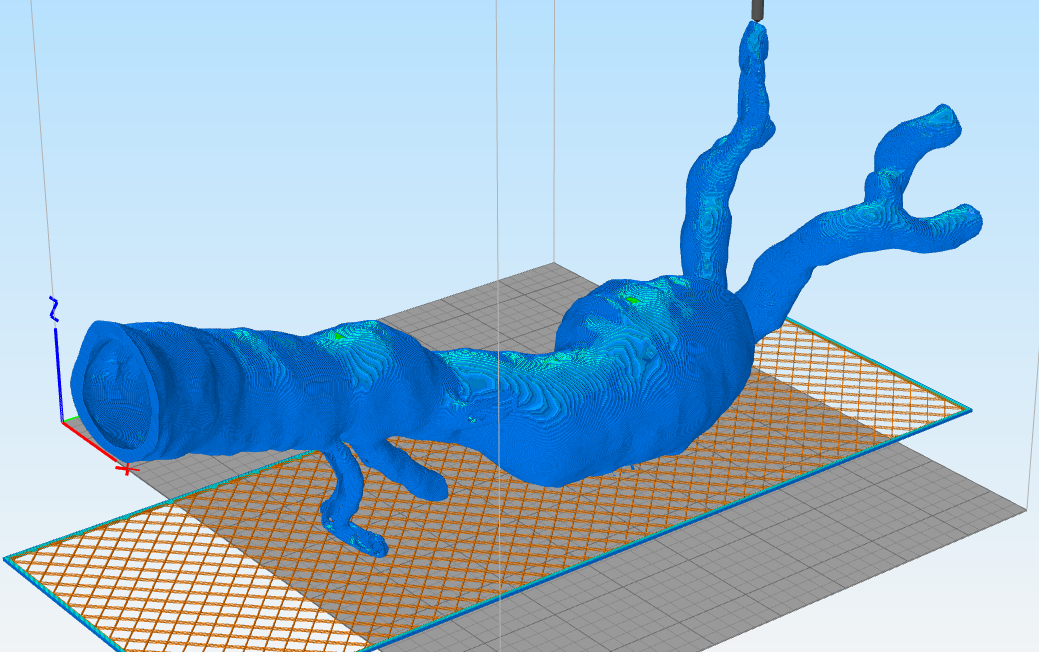

A life-sized 3D printed abdominal aortic aneurysm model was fabricated using the Dynamic Molding process, starting as a digital STL file before undergoing a virtual 3D reconstruction via specific imaging software to reveal the patient’s arterial tree. According to 3Deus Dynamic, this achievement is a ‘world first’ and marks a major advance in the development of complex silicone anatomical models.

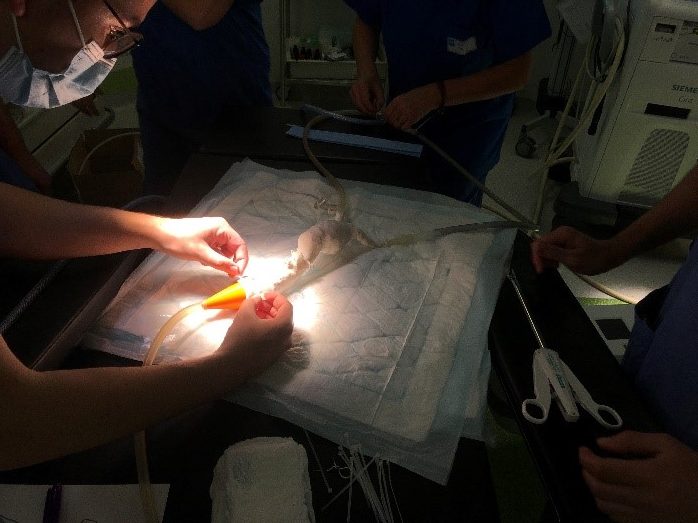

The 3D model contained a hollow, flexible, and easily-manipulated structure with resolved anatomical details, such as the celiac trunk, renal arteries, superior mesenteric artery, and arteries common iliac. Feugier and his team validated and evaluated the 3D model in catheterization conditions to demonstrate their capability for use within the simulation and planning of complex arterial procedures within vascular surgery.

The Dynamic Molding process can also be extended to other flexible anatomical model projects for the management of pathologies requiring planning and personalized intervention.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews, and webinar replays.

Featured image shows the 3D printed aorta model being used in real conditions in the operating room. Photo via 3Deus Dynamics.