US 3D printer OEM 3D Systems has announced intentions to significantly increase the expansion of its regenerative medicine and bioprinting offerings after seeing “tremendous progress” in the development of 3D printing systems for solid-organ scaffolds.

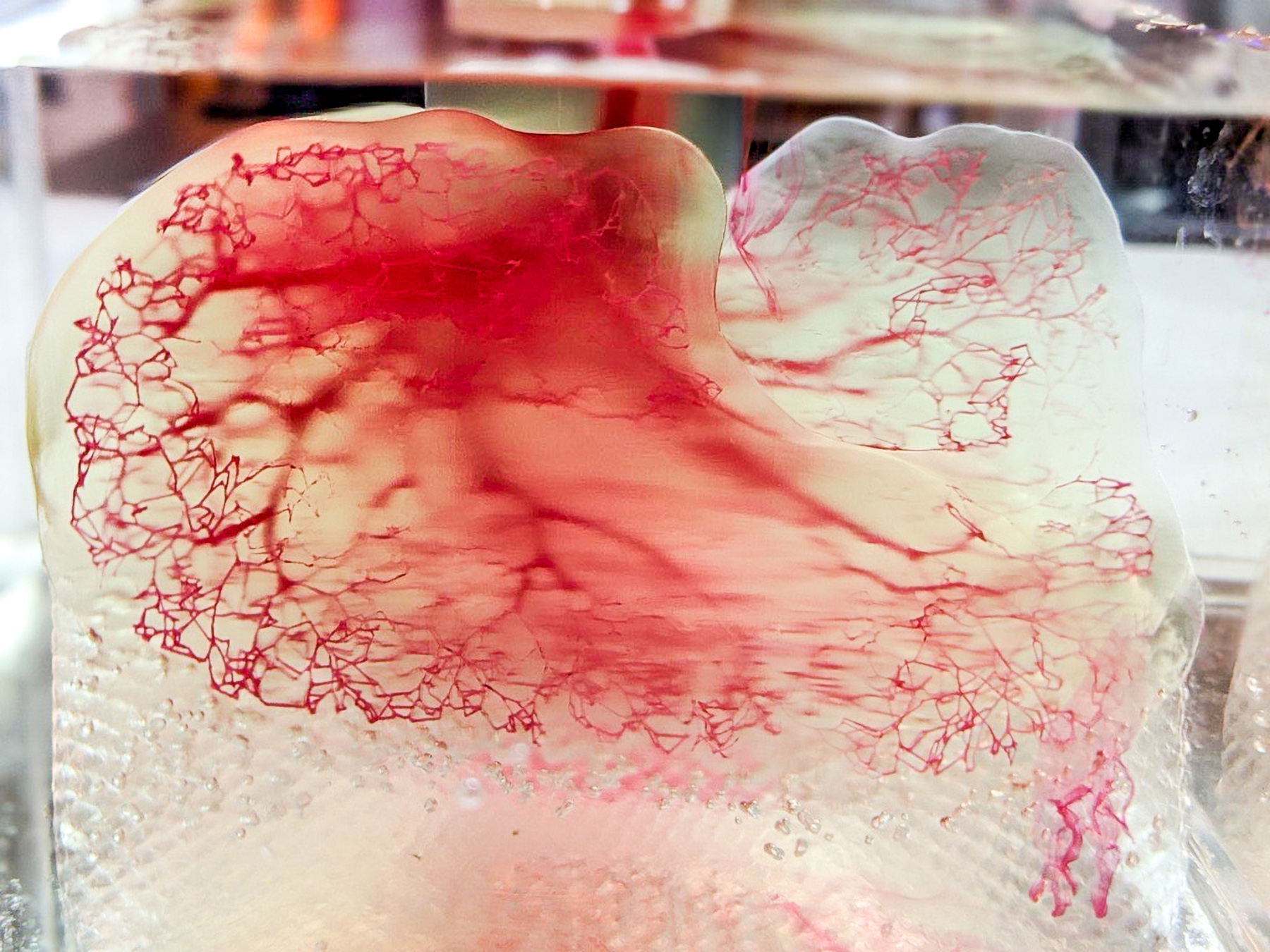

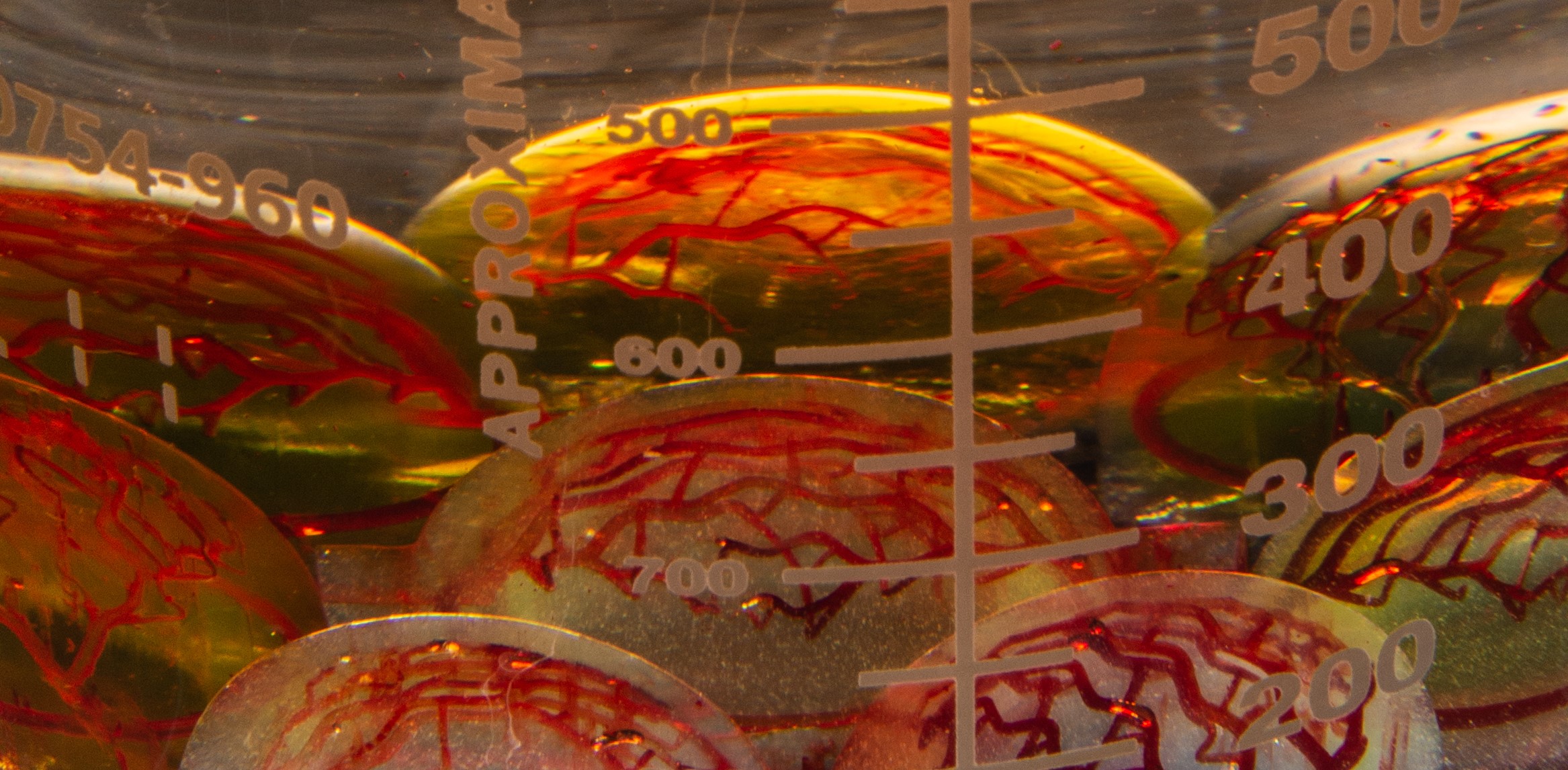

Carried out in partnership with United Therapeutics Corporation and its organ manufacturing subsidiary Lung Biotechnology PBC, 3D Systems’ efforts in this area include the establishment of a 3D printing platform capable of full-size, vascularized, and rapid micron-level printing for lung scaffolds, named Print to Perfusion.

As a result of this success, and the triumph of other recent initiatives by 3D Systems in the field of regenerative medicine, the firm intends to further invest in, develop, and commercialize offerings for the sector in a bid to accelerate long-term, profitable growth within healthcare.

“The progress that Chuck Hull and his team have made over the last three years, in collaboration with the team from United Therapeutics, has been absolutely remarkable,” said Dr. Jeffrey Graves, President and CEO of 3D Systems. “Through unique developments in new printer hardware, software, and biomaterials technology, they have laid the foundation needed for accelerated commercialization of bioprinting at 3D Systems.

“Taking a strong application focus, we will now expand our commercialization efforts in this nascent industry, which we believe will experience significant growth over the next decade.”

Increased bioprinting capabilities with Print to Perfusion

In 2020, 3D Systems and United Therapeutics achieved progress in the development of the Print to Perfusion process, which is designed to enable the 3D printing of high-resolution scaffolds that can be perfused with living cells to create tissues. Combining 3D Systems’ capabilities in additive manufacturing hardware, software, materials, and United Therapeutic’s expertise in regenerative medicine, the two companies have achieved advances in lung modeling and material formulation and handling to improve the capabilities of 3D Systems’ bioprinters and biomaterials for lung manufacturing.

The Print to Perfusion process enables the printing of large, vascularized, and highly detailed hydrogel scaffolds that have the potential to open up a range of new tissue applications elsewhere in the body. The capabilities offered by the platform could also facilitate novel laboratory testing methods to accelerate drug development while minimizing the need for animal testing.

“Our collaboration with 3D Systems has allowed us to take a first-principles approach to regenerative medicine,” said Derek Morris, Associate Director of Engineering at Lung Biotechnology PBC. “The full sze, vascularized lug scaffolds produced by 3D Systems’ printers allow our cellularization teams to focus on our mission to build an unlimited supply of transplantable organs.”

To advance these efforts, 3D Systems is expanding and tailoring its high-speed Figure 4 technology to bioprinting and regenerative medicine. Figure 4 has previously been applied to the manufacture of custom hearing devices, and saw an expansion of its material portfolio last year to increase the range of applications for manufacturers in the 3D printing sector.

“Over the last years as bioprinting and regenerative medicine have evolved, we’ve seen a growing need to place cells at high resolution in a nurturing matrix to produce complex tissues,” said Chuck Hull, Co-founder, Executive Vice President, and CTO at 3D Systems. “Precise 3D printing with hydrogels, followed by perfusion of cells into the printed scaffold is the best way to achieve this, and we are thankful our work with United Therapeutics has given us the opportunity to advance and perfect this technology.”

Increasing R&D efforts in regenerative medicine

Having previously cited healthcare as an area of growth for 2020 and after experiencing significant progress in this area, 3D Systems is now flushing additional resources into its regenerative medicine R&D activities to widen the scope of potential applications and increase its expertise and technological know-how within this field.

The firm previously announced a collaboration with Israeli bioprinting material developer CollPlant for the joint development of tissue and scaffold bioprinting processes for third party collaborators. CollPlant developed the proprietary recombinant human collagen (rhCollagen) BioInk technology, which is also being used in partnership with United Therapeutics for the development of 3D bioprinted lung transplants.

3D Systems has also partnered with Belgium-based biotechnology firm Antleron to advance regenerative products for personalized patient care. The collaboration’s goal is to enable sustainable and personalized manufacturing of cell and gene therapies, vaccines, tissues, and organs by integrating technologies such as 3D printing, bioreactors, and Artificial Intelligence (AI).

Elsewhere, 3D Systems’ VSP surgical planning platform for orthopedics has enabled the planning of over 140,000 patient-specific surgeries and produced more than two million medical devices. The platform obtained FDA clearance in 2019 and has since been cleared for the printing of maxillofacial surgical guides designed to provide surgeons with greater access and visibility to the surgical site. 3D Systems has also received 510(k) clearance for its Vantage Ankle PSI patient-specific 3D printed surgical ankle instrument, which is designed for medical device manufacturer Exactech’s Vantage Total Ankle System.

3D Systems has also previously collaborated with Align Technology, makers of Invisalign clear dental aligners, to provide the firm with customized hardware, software, and material solutions. Meanwhile, 3D Systems’ NextDent 5100 digital dentistry platform is used for prosthodontic and orthodontic production at dental laboratories and clinics.

Graves concluded: “We expect these efforts to bring substantial benefits to the healthcare patients in critical need, both through direct applications within the human body, as well as in accelerating the development of drug therapies in the pharmaceutical industry.

“We anticipate regenerative medicine to be an exciting growth driver for our healthcare business over the next decade.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Be sure to subscribe to the Another Dimension podcast on your chosen podcast player to make sure you never miss an episode.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows human vasculature model created using Print to Perfusion process” Image via United Therapeutics.