U.S. 3D printer manufacturer 3D Systems (NYSE: DDD) has agreed a deal to acquire Artificial Intelligence (AI) software firm Oqton.

Set to be finalized in Q4 2021, the agreement will see 3D Systems pay Oqton shareholders $180 million in cash and stock, in return for full control of their business. By integrating its existing offering into Oqton’s Manufacturing Operating System (MOS), 3D Systems now aims to create a platform that’s “instrumental in advancing AM,” and is expected to increase its annual software income to $100 million by 2025.

“We are excited about joining with 3D Systems,” said Dr. Ben Schrauwen, CEO and Co-founder of Oqton. “At the same time, we bring our deep expertise in AI, automation, robotics and machine learning (ML), which will help our customers and partners to scale and connect different manufacturing processes in a wide range of healthcare, bio-tech and industrial market verticals.”

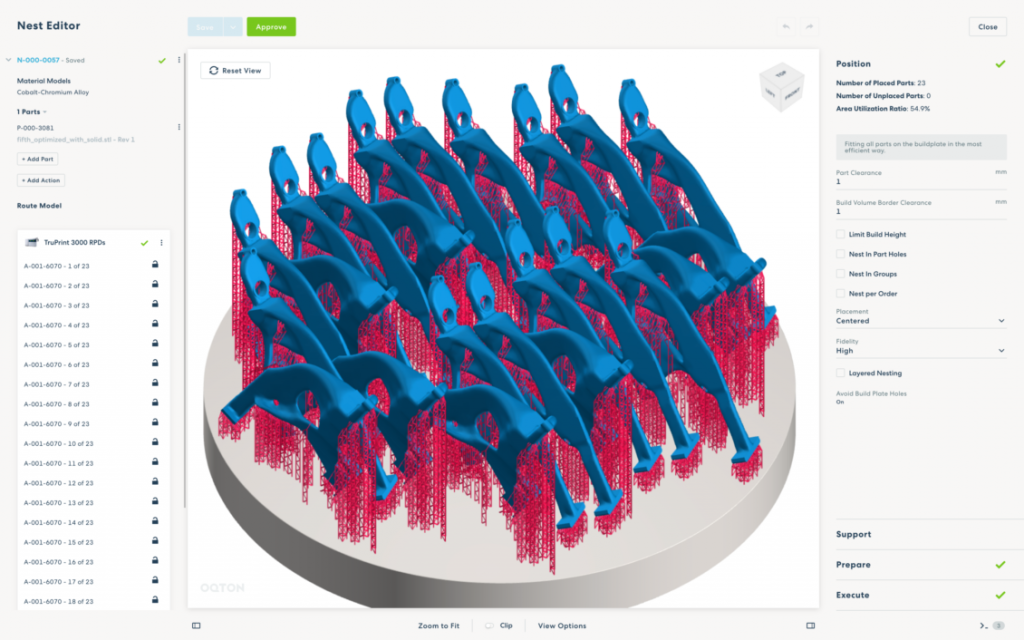

Oqton’s cloud-based platform

Designed to help the users of advanced technologies streamline, manage and scale their production workflows, Oqton’s platform centers around its AI-led MOS. Thanks to its in-built ML and Industrial Internet of Things (IIOT) capabilities, the software is able to automate, accelerate and optimize the throughput of adopters, thus it has begun to attract considerable interest within the 3D printing industry.

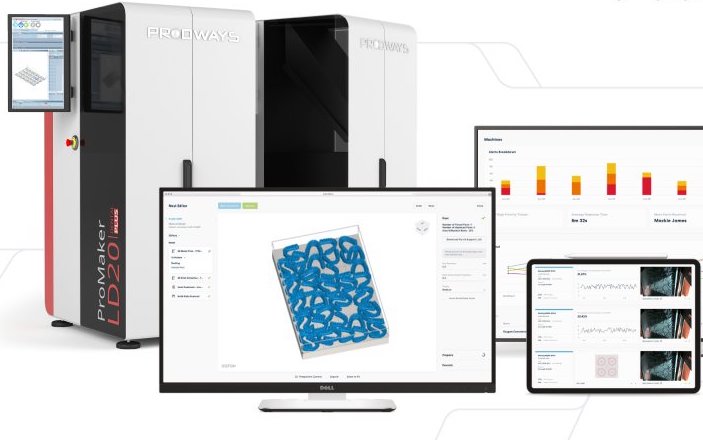

Earlier this year, Oqton raised $40 million in funding for its platform, which it has since deployed on fostering commercial partnerships across 3D printing, robotic welding and CNC machining. In one such collaboration, the firm has agreed to package its software with Prodways’ machines, adding its MOS to its partner’s offering, to provide system users with a “one-stop” cloud management platform.

In the past, Oqton is also said to have worked with EOS, Sisma, TRUMPF and Sandvik, and having acquired the company’s technologies, 3D Systems now believes they could have applications ranging from healthcare to aerospace and automotive.

“Customers across our industrial and healthcare segments are accelerating the adoption of AM into production environments,” said Dr. Jeffrey Graves, CEO of 3D Systems. “They’ve increasingly identified the need for a manufacturing software platform that can easily and intelligently incorporate, not only the printers themselves, but all digital production systems and enterprise software.”

“Oqton’s learning capabilities optimize and automate manufacturing elements in a manner that is not available [elsewhere] today.”

3D Systems buys into AI

In particular, 3D Systems has chosen to acquire Oqton due to its MOS, which it believes has the potential to enable users to continually improve the performance of their machines within “full production environments.” According to Graves, its new subsidiary’s platform is able to achieve this due to its ML approach, which future-proofs it against hardware updates and allows it to adapt to different platforms.

“Oqton’s MOS seamlessly leverages enterprise information and data in the customer’s current ERP, MES, PLM, and CRM systems, as well as the full range of shop floor manufacturing operations and software,” explained Graves. “This allows customers to use their choice of manufacturing and automation equipment on the shop floor to meet their unique factory needs.”

“The use of APIs to create ease of linkage between these systems is a distinctive attribute of the Oqton MOS.”

Having now struck a deal to acquire Oqton, 3D Systems intends to allow it to continue operating independently, with data confidentiality and security protocols being put in place to protect user data. However, the company also aims to integrate its existing 3DXpert, 3D Sprint, Geomagic and Additive Works’ Amphyon programs into Oqton’s MOS platform as add-ons, once the deal goes through.

In doing so, 3D Systems says that it hopes to build a platform capable of “allowing for the rapid adoption of even the most challenging production workflows,” that enables users to “enhance their competitive position,” which in turn, earns it a larger share of what it views as a $1.5 billion ‘smart manufacturing’ market, that could hit $6 billion by 2025.

3D printing’s AI revolution

Over the last year, a significant amount of progress has been made in the development of both ML and AI-driven 3D printing technologies. In March 2021, Senvol announced that it was developing a machine learning software with “‘additional capabilities,’ that’s specifically being designed to address the production needs of the U.S. Department of Defense.

In terms of commercial systems, Markforged has also embraced AI with the launch of its new AI-based Blacksmith software for its X7 3D printer. The program effectively uses a patented scanning algorithm to measure the precision of parts as they’re being printed, and collect data that’s used to improve the quality of later jobs.

Elsewhere, on a more experimental level, researchers at Oak Ridge National Laboratory (ORNL) have developed an AI-driven real-time monitoring software of their own. Known as ‘Peregrine,’ the program is currently capable of monitoring the metal 3D printing process, but with further R&D, it could be used to turn systems into ‘self-correcting machines.’

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a screenshot taken from Oqton’s Additive software. Image via Oqton.