Leading 3D printer manufacturer 3D Systems (NYSE:DDD) has release two new entry-level metal additive manufacturing systems.

Both of the new machines, the DMP Flex 100 and the the DMP Dental 100, work using the company’s laser-based Direct Metal Printing (DMP) technology, and are targeted to broaden the potential customer base for industrial-grade additive manufacturing.

Kevin McAlea, EVP metals and healthcare, 3D Systems, comments:

“Both solutions feature levels of throughput, print quality, ease of use and material choice that put them in a class by themselves.”

3D Systems DMP Flex 100

The DMP Flex 100, as the name suggests, is designed to be application-flexible. As an introductory system, it is best suited to R&D, development, and low-run production.

The Flex 100 can achieve double the throughput of the previous entry-level ProX DMP 100, and is accomplished at creating prints with fine details and thin walls.

Build volume is measured as 100 x 100 x 80 mm (3.94 x 3.94 x 3.15 in), small metal part print accuracy is typically +/- 50 μm (+/- 0.002 inches), for large part it is +/- 0.2%, and repeatability from part to part is approximately 20 μm (0.0008 inches).

3D Systems DMP Dental 100

As Vyomesh Joshi (VJ), President and CEO of 3D Systems, explained earlier in the year, “dentistry is the critical market for 3D Systems.” In the second product release of the day, 3D Systems adds to its ever-growing dental portfolio with a metal partner to NextDent 5100.

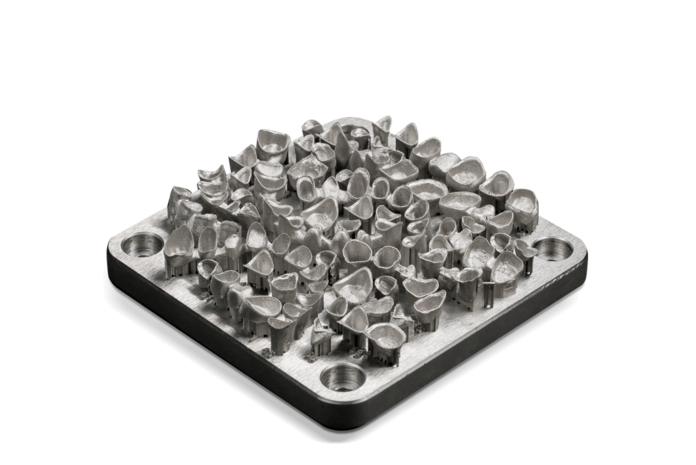

The DMP Dental 100 is a system that delivers maximum price to performance ratio for metal 3D printed crowns and partials. It has a build platform measuring 3.94 x 3.94 x 3.15 in (100 x 100 x 80 mm).

In an example use case, a plate containing 90 crowns can be 3D printed in under four hours, with an average post removal time of around 25 minutes.

Print accuracy is typically +/- 0.002 inches (+/- 50 μm), and, like the DMP Flex 100, the repeatability from part to part is 0.0008 inches (20 μm).

McAlea concludes, “We believe these 3D printing solutions will further expand the adoption of metal additive manufacturing by designers and engineers, researchers, manufacturers and dental professionals.”

For more new product releases and news subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Sign up to 3D Printing Jobs to post and find new opportunities near you.

Featured image shows dental implants 3D printed by 3D Systems customer Yndetech on the ProX DMP 100. Photo via 3D Systems