2017’s Salone del Mobile Milan Design Week from April 4-9 is exhibiting some of the most cutting edge uses for sculptural 3D printing. The eponymous architecture firm of the late Zaha Hadid is exhibiting at the event, and MIT’s Neri Oxman has 3D printed glass sculptures in collaboration with luxury car sponsor Lexus.

Computer simulated organic design

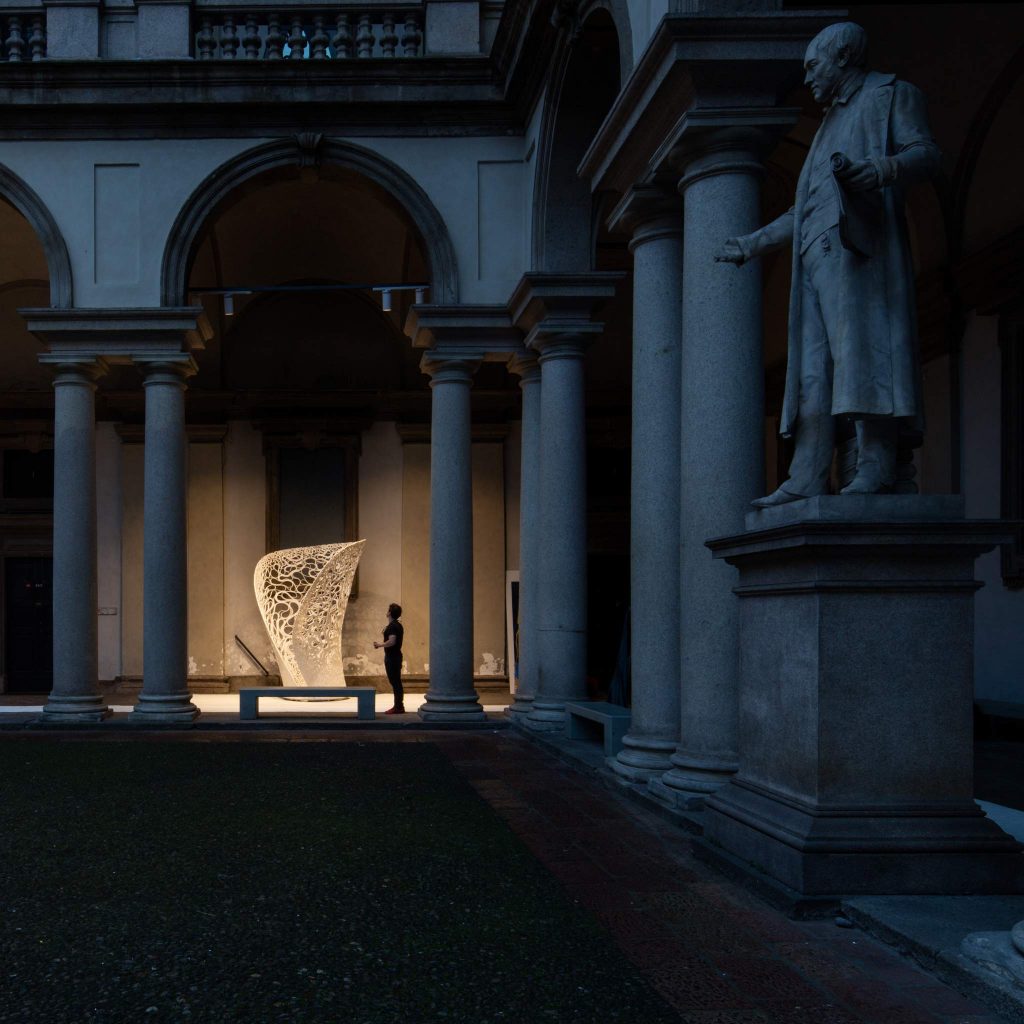

Thallus is 3D printed in one continuous strip of PLA plastic 7km long. To realize the plant-like sculpture, Zaha Hadid Architects’ Computational Design (ZHA CoDe) research group used an extruder attached to a robotic arm. The fluid details were generated to demonstrate the possibilities of “what can now be achieved in terms of mechanisation and customisation in the architecture, construction and engineering industries.”

In hot-wire cutting the edges, the detailed strip was attached to a cylindrical base, and now stands at 9.1 feet tall.

The finished structure is part of ZHA CoDe’s experimentation with computer generated geometries, defined by “proximity to boundaries”, “angled direction of rulings” and structural requirements to allow it to stand.

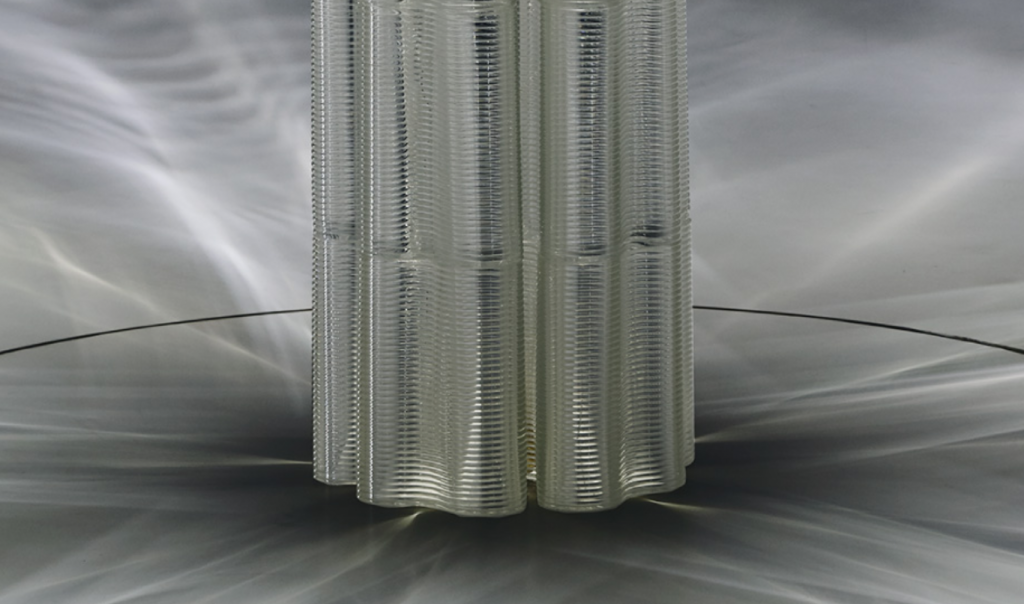

3D printed glass sculptures

The “YET” philosophy is at the core of Lexus’ luxury vehicle designs, i.e. “spacious YET aerodynamic”. YET is also the topic of the company’s 2017 Grand Prix Design Award announced in Milan during design week.

To celebrate this philosophy, Lexus commissioned the help of Professor Neri Oxman and her MIT research team at the Mediated Matter Group, also behind the colorful Vespers death mask series 3D printed in collaboration with Stratasys. The outcome is an installation of 3D printed glass columns “utilizing an ancient material YET a modern technology”, and playing with diffraction of light.

The columns make use of MIT’s technology for layering molten glass. The technique is tricky as it must exactly balance build chamber conditions to ensure adequate support of successive glass layers. The ridges created also change the optical qualities of the glass.

Other companies using 3D printing to express architectural creativity include New York’s SHoP Architects, that created the Flotsam and Jetsam bamboo filament pavilion for Design Miami, and Italy’s Politecnico di Milano, that used WASP 3D printers for a bone-inspired structure also in Milan.

The overall effect of such projects is inspiring to the limits of 3D printing materials and hardware. To stay up-to-date with sculptural and architectural 3D printing sign up to the 3D Printing Industry newsletter and follow our active social media sites.

Featured image shows detail of Thallus by Zaha Hadid Architects. Exhibited at the Pinacoteca di Brera gallery in Milan. Photo by Luke Hayes