Though arguably one of the more famous 3D printed objects, the 3DBenchy ‘jolly torture-test’ boat used to test the capabilities of a 3D printer is not particulary seaworthy. 3D printing for actual maritime purposes is still a relatively unexplored territory for many additive manufacturers. That’s not to say that the shipbuilding industry hasn’t been listening.

Earlier this week the National Institute for Shipping and Shipbuilding (NISS) in the Netherlands set out their blueprint for construction in the maritime sector for the next 30+ years, expecting 3D printing to turn shipbuilding on its head.

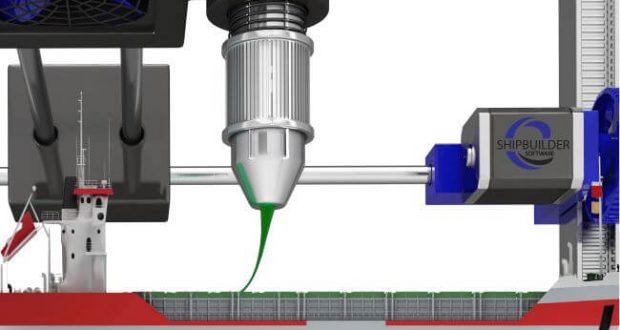

We’re going to need a bigger 3D printer

Geert Schouten the director of Shipbuilder, a company that provides new software for the maritime industry, was part of the team that created the plan. He says:

The combination 3D printing, digitalization and robotization is developing very fast. Other sectors are moving ahead quite fast already, so I expect some trendsetters to stand up in the maritime sector soon too. These trendsetters will completely renew the maritime sector. Real innovators, maritime game changers.

He commented that the maritime sector has been hanging on to legacy and traditional systems for some time, and has found that people in the industry don’t feel threatened because there is no printer capable of 3D printing an entire ship. Schouten added, “That is an incorrect way of thinking, because it is based on the current possibilities for designing and building ships.” Recognising 3D printing’s potential in production the software company director said,

The first digital ship builders will conquer the maritime world quicker than people think. They will leverage digitalization, robotization and 3D printing successfully.

Planes, (sea)trains and automobiles

Aerospace is, of course, a leader in the adoption and industrialization of additive manufacturing. Both GE in the U.S. and the French aerospace manufacturer Airbus are well known examples. Airbus have an ongoing partnership with Stratasys and standardized the ULTEM™ 9085 3D printing material for use in its A350 XWB aircraft mid-October 2016. Additionally, Oak Ridge National Laboratory (ORNL) earned the Guinness World Record for largest 3D printed part with a trim-and-drill tool for Boeing airplanes. That record was then superseded by SHoP architects’ 3D printed pavilion Flotsam and Jetsam this year.

3D printing is also making inroads into car manufacturing, with Divergent3D printing the Blade supercar in 2015 and subsequently entering into partnership with PSA Groupe who manufacture Peugeot and Citroën cars in September of this year. Larger automakers have used 3D printing as a rapid prototyping tool for many years.

Since we can print houses, cars and airplane parts, does the technology make sense in the ship building world? While large format metal 3D printing systems do exist these are typically for high value components, for example Sciaky or Norsk Titanium working with aerospace manufacturers. Making the vast hull of a ship is a project we have not seen.

However, at a smaller level and as innovation starts to take hold of maritime manufacturing, it may be worth looking to HanseYachts who developed a 20-meter-long 3D printer and successfully 3D printed the hull of a yacht earlier in 2016.

With maritime industry experts looking at the 3D printing market to see where value can be added more news is expected.

Featured image shows a typical 3DBenchy boat with chimney smoke attachment Image via: Akira 3dp0.com