As storage for manufacturers’ spare parts are moving away from industrial sized warehouses to big memory hard-drives, computer aided design (CAD) has been given a new lease of life, especially when paired with a 3D printer. A product’s design cycle is now dramatically cut down from months to weeks, and companies’ control over the process is better than ever before. 3D technologies are enhancing not only the ability to create something new, but also to reverse engineer those products that already exist.

Metrology and scanning

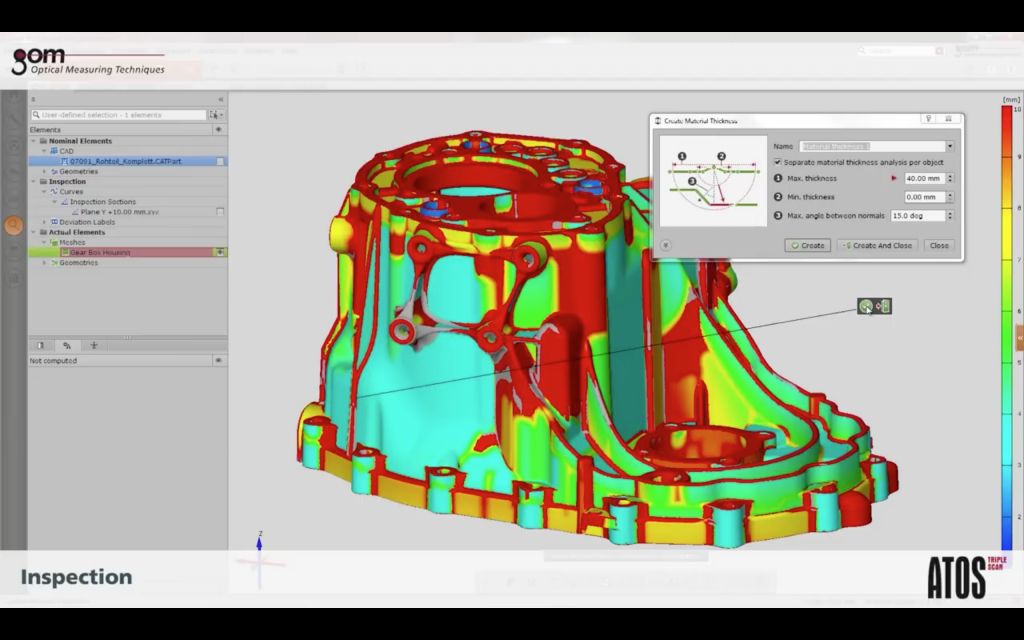

Germany-based metrology specialists GOM GmbH are one of the companies showing how 3D scanning is applied across industries including aerospace, power generation, and transport. GOM has over 100 service partners across Europe and North America who provide and use scanning services to their clients.

Use cases of reverse engineering in automotive industries

In North America GOM service partners blupointscan specialise in reverse engineering services. In addition to creating a housing for an aircraft control motor, blupointscan’s projects also successfully replaced the seatbelt cover for a vintage Ferrari Dino in their projects.

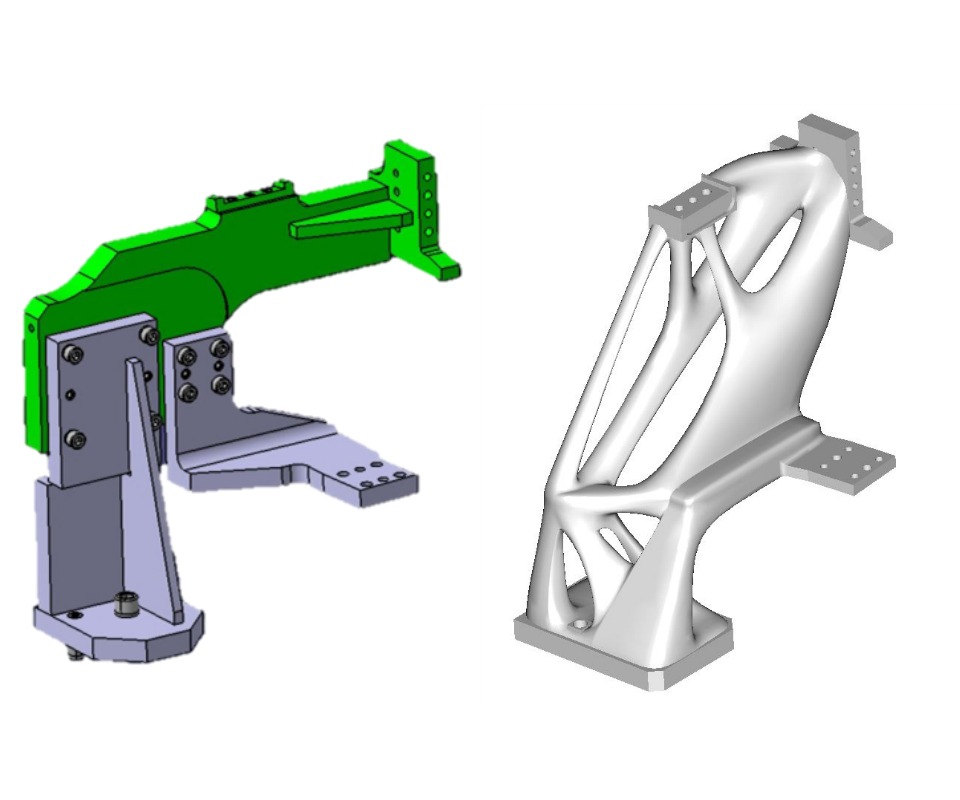

Comau use additive manufacturing and CAD to work on machines process automation as part of the Fiat Automobile Group in Italy. A clamping unit, used in welding and assembly, is provided as an example of how 3D technologies has managed to streamline a part, which usually comes in three.

Consolidation into one piece means it is easier to replace or add a new clamp, and has less points of weakness (i.e. the screws).

Reverse engineering in software

Autodesk are one software producer who have designed their programs to provide streamlined solutions to designs for 3D printing. The company are also holding a competition to help more people understand how scanning and CAD combine to enhance a product. Entrants to the competition were asked to select an object related to their hobbies and improve upon its capabilities.

This kind of ingenuity and close examination of parts and products is key to the acceleration of manufacturing to meet the ideals set out by Industry 4.0. At 3DPI we are always looking for people bringing new ideas to 3D printing and design. If you have anything you’d like to share, remember you can send us an email here.

Featured image shows a 3D printed steampunk world designed and printed by Mauricio Chong. Photo via: macburro on Shapeways.