This is a guest post in our series looking at the future of 3D Printing. To celebrate 5 years of reporting on the 3D printing industry, we’ve invited industry leaders and 3D printing experts to give us their perspective and predictions for the next 5 years and insight into trends in additive manufacturing.

Felix Ewald is the CEO & Co-founder of DyeMansion. DyeMansion offers automated manufacturing solutions for the production facilities of the future. The in-house developed post-processing solutions cover every step after the production of an additive manufactured part and are specifically optimized for laser sintered plastics

Industrial manufacturing with plastics and 3D Printing: The next 5 years by Felix Ewald

It’s a very exciting time for additive manufacturing plastics. Although metal 3D printing gained a lot of attention in the past two years and shifted the hype away from plastics, this technology and its latest developments shouldn’t be underestimated in the future.

HP’s Multi Jet Fusion is hitting the market with full power and Carbon’s case studies show that SLA is still in the game when it comes to industrial manufacturing in the future, 3D systems announced huge price drops for their SLS printers, new materials are extending the market and last but not least, small & affordable SLS machines bring high priced manufacturing technologies to the masses without any big investments for smaller companies.

Altogether, good times ahead for the AM plastic market and thus good times for DyeMansion, since our goal is to industrialize the post production for powder based plastics. So what will happen in the next 5 years?

![DyeMansion’s industrial post-processing systems fo AM: Powershot C for automated depowdering, DM60 coloring system, Powershot S for automated surface finish [L-R]](https://3dprintingindustry.com/wp-content/uploads/2017/05/Post-processing-systems_DyeMansion-1024x576.jpg)

The main cost drivers for AM plastics are speed and costs of the machines, material- and personnel cost. Competition will be the accelerator for the first two points. Especially the printing speed will increase dramatically within the next 5 years. Multi Jet Fusion / High Speed Sintering / CLIP are just the beginning of a race towards ultimately fast printers.

The decrease of material costs is a bit more complicated to achieve since 3D printing of plastics is a very complex topic and materials are usually fixed to each technology. This does not only mean that one is generally required to buy the materials from the machine supplier but that it’s very difficult for new suppliers to enter the market. In my opinion, there will be only a small decrease regarding the material costs over the next 5 years. The main driver for cost savings will be faster and more efficient machines as well as automated post production steps.

Powder based technologies vs. Stereolithography

While Carbon bets on SLA, HP & EOS are focused on powder based technologies and 3D Systems does both. Each technology has its advantages.

Whereas SLA is more popular in the US, powder bed fusion is the leading technology in Europe. The next 5 years will definitely show which technology will be the holy grail when it comes to future manufacturing. At DyeMansion, we rely on powder based technologies. No support structures, real materials & scaleable productivity. We believe that these aspects are the keys to high volume manufacturing.

Expectations & adoption of different industries

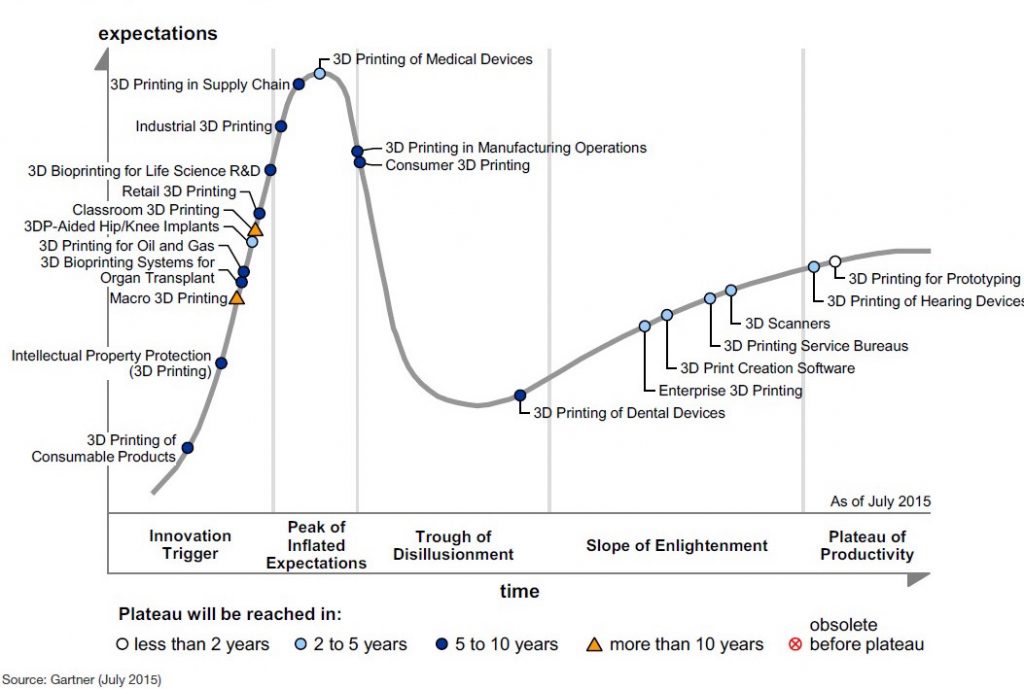

By adoption I mean the slope of enlightenment of the Gartner hype cycle. It remains to be seen how big the impact of additive manufacturing will be in 5 years. 3D printing has a lot of big advantages compared to conservative manufacturing technologies. Obviously there are some restrictions which do not fit into the mindset of the old economy.

It will take some more time for the industry to adopt the additive way of thinking. One important topic of that adoption progress will be the whole environment around the printer. Of course, everything starts with the mindset, but there are a lot of other impacts around the printer & the costs which can accelerate the adoption of additive manufacturing.

Large AM show cases & projects, the commitment of the big industry players, software, education, the automation of post-production and many more. The race for future manufacturing in AM plastics has just started. The next 5 years will definitely be a blast for every 3D printing enthusiast out there.

This is a guest post in our series looking at the future of 3D Printing, if you’d like to participate in this series then contact us for more information.

For more insights into the 3D printing industry, sign up to our newsletter and follow our active social media channels. Let us know your thoughts about this perspective on the future of 3D printing in the comments below.

More information about DyeMansion is available here.

Featured image shows Felix Ewald, CEO & Co-founder of DyeMansion.