This is a guest post in our series looking at the future of 3D Printing. To celebrate 5 years of reporting on the 3D printing industry, we’ve invited industry leaders and 3D printing experts to give us their perspective and predictions for the next 5 years and insight into trends in additive manufacturing.

Shlomo Magdassi is a professor of chemistry at the Institute of Chemistry and the Center for Nanoscience and Nanotechnology at the Hebrew University of Jerusalem. Shlomo Magdassi is the Head of the Institute of Chemistry, and of The Center for Functional and 3D Printing of the Hebrew University. Recently Shlomo Magdassi presented his update on the industry at Hebrew University’s NEXUS:ISRAEL conference.

Dr. Michael Layani is a research fellow at Nanyang Technological University, Singapore and a researcher at the Institute of Chemistry of Hebrew University of Jerusalem. His research field is material science and functional and 3D printing.

3D Printing: The next 5 years by Dr. Michael Layani and Shlomo Magdassi

The world of 3D printing is blooming. Although the various technologies such as binder-jetting and photo-polymerization 3D printing have been around for the past two decades, it is only within the recent years that the field has seen so many novel discoveries.

These new discoveries are in many related fields, such as new printers (rapid printing suitable for industrial production), new processes (from knitting to paper-based printing), and last but not least: new materials. As material scientists, the last field is of the most interesting to us, as manifested in the significant increase of publications in high-impact journals such as Science, Nature and Advanced Materials.

While 3D printing of plastics (molten or polymerized) and metals have been used extensively since the early 80s, such materials as ceramics, composite materials, hydrogels and responsive polymers are expected to completely change the 3D printing world.

So far, most activities are related to making 3D objects, while focusing mainly on their mechanical properties. We expect that the next breakthroughs will come from adding functionalities to the printed objects, and combining new materials with faster printing technologies. The Functional and 3D Printing Center of The Hebrew University of Jerusalem is moving in the direction of functional printing, by combining the expertise of the various researchers at the university, in scientific disciplines ranging from chemistry, physics, computer science, biology, agriculture and medicine to art and design.

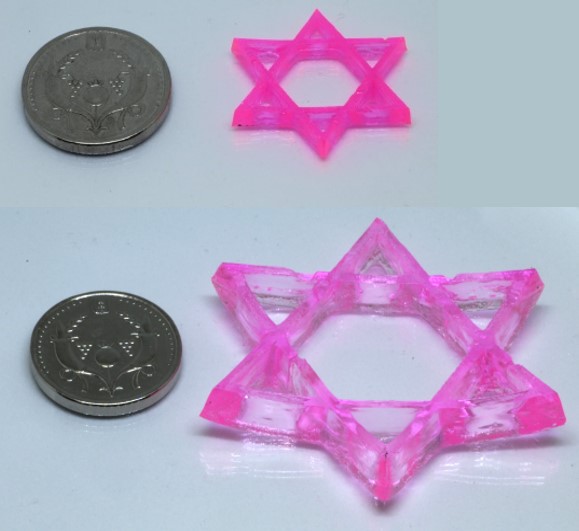

Recent examples of new materials and printed devices that demonstrate functional 3D printing objects include responsive materials (4D printing) such as shape memory polymers which respond to the an external trigger (heat or magnetic field), moving parts of soft robots, flexible light sensors, light emitting devices and hydrogels for biomedical applications.

Future directions would focus on devices for human-computer interfaces, 3D printing of complex structures such as meta-materials, artificial organs and medical implants, functional food and embedded electronics. The latter is important for the emerging field of Internet of Things (IoT) and wearable electronics.

Overall, we envision that real breakthroughs will emerge in the coming years from research focused at the interface between the various scientific fields. We expect that the world of 3D printing will move towards combining advanced high throughput printing technologies and new materials for rapid production of 3D objects that cannot be produced otherwise.

Finally, the proverbial “holy grail” of the community is yet to be invented. That would be a printer with the ability to print different classes of materials, to use different printing platforms and integrate post-printing processing. This ability would really enable freedom of design and therefore industrial production of fully functional 3D objects.

This is a guest post in our series looking at the future of 3D Printing, if you’d like to participate in this series then contact us for more information.

For more insights into the 3D printing industry, sign up to our newsletter and follow our active social media channels. Let us know your thoughts about this perspective on the future of 3D printing in the comments below.

More information about The Center for Functional and 3D Printing is available here.