This is a guest post in our series looking at the future of 3D Printing. To celebrate 5 years of reporting on the 3D printing industry, we’ve invited industry leaders and 3D printing experts to give us their perspective and predictions for the next 5 years and insight into trends in additive manufacturing.

Chris Labelle is the Co-founder and COO Mosaic Manufacturing. Aimed at designing products that facilitate digital customization, Mosaic Manufacturing has produced a range of 3D design software and are devolopers of the Palette system that allows users to 3D print in multiple filaments and colors.

3D Printing: The next 5 years by Chris Labelle, Co-founder and COO of Mosaic Manufacturing

Over the next 5 years, 3D printing will evolve from a manufacturing technology that is used in isolation to one that forms an essential component of new manufacturing processes. Combining 3D printing with other forms of additive manufacturing technologies will allow consumers to derive value from the customization capabilities that 3D printing offers, while also gaining access to the range of products that can be created by other manufacturing technologies.

This combining of manufacturing technologies and processes will have a few significant impacts on how we create and consume products:

- 3D printing will become more efficient and economically viable for manufacturing at scale.

- Products manufactured in traditional ways will gain elements of customization.

- Consumers will benefit as more automation and customization will enable the delivery of more valuable products at comparable costs.

Reliability, repeatability, and increased automation are driving 3D printers to become part of more supply chains every year. Type A Machines’s Print Pod, Voodoo Manufacturing’s Project Skywalker, and 3D Systems’s Figure 4 are leading signals that 3D printers will increasingly play more significant roles in manufacturing processes that are currently dominated by traditional methodologies like injection molding.

These systems and other new technologies that will emerge over the next five years will allow 3D printing to grow substantially and capture more of the 12 trillion dollar manufacturing market.

One of 3D printing’s key differentiating factors is its ability to create customized products. Decreased costs in manufacturing processes that enable customized products will make them more financially accessible for sizable customer segments across different verticals.

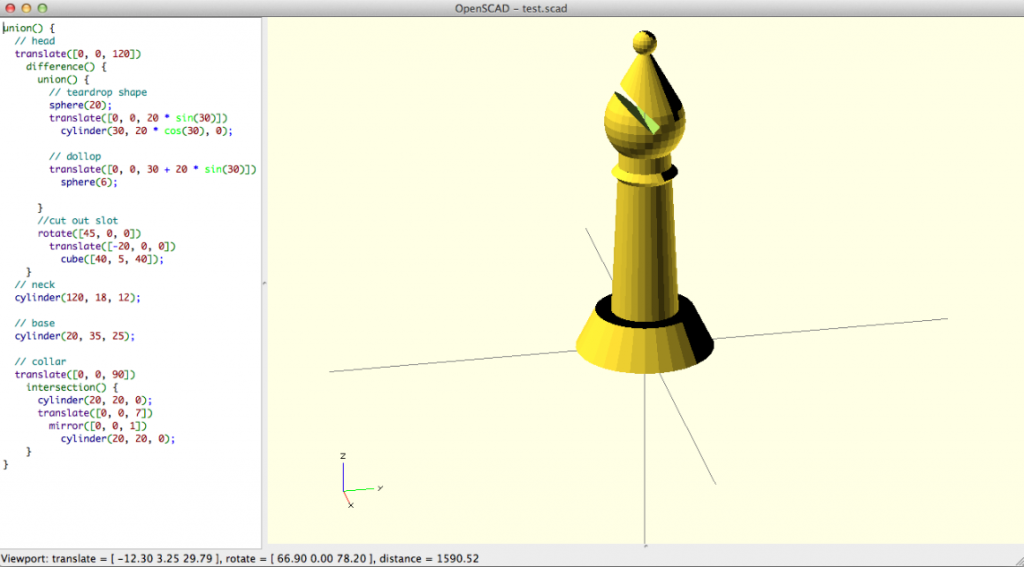

We’re playing our role in this shift by enabling regular users to customize 3D models using the concept pioneered via OpenSCAD—parametric modelling. We seek to empower regular consumers with the power to manipulate models. Combining this power with customized manufacturing processes will increase the popularity of 3D printing in manufacturing processes and bring them into the mainstream.

We’re commercializing a new approach that makes it economically sensible for manufacturers to bring 3D printing into their current methods of manufacturing in a fully automated way. This software allows 3D printed polymers to be combined with any other input material. It enables the binding of polymers with a non-printed parts like CNC milled parts and casings, electronics, screens, and non-3D printed polymers (such as those made with injection molding).

The next-generation of product customization platforms will be much more newbie-friendly

With companies pioneering new approaches to digital manufacturing, and growing partnerships with companies in different consumer verticals, 3D printing will quickly move beyond its current capabilities. This shift will allow 3D printing to begin to take over from more traditional manufacturing processes, especially in areas where consumers can benefit from customized or personalized products.

This won’t happen overnight, but five years from now, we’ll marvel at the number of products that were once only available in standardized sizes, and not highly customized to individuals’ needs.

This is a guest post in our series looking at the future of 3D Printing, if you’d like to participate in this series then contact us for more information. For more insights into the 3D printing industry, sign up to our newsletter and follow our active social media channels. Let us know your thoughts about this perspective on the future of 3D printing in the comments below.

Don’t forget that you can vote now in the 1st annual 3D Printing Industry Awards.

More information about Mosaic Manufacturing is available here.

#futureof3Dprinting

Featured image: Mosaic Manufacturing co-founder and COO Chris Labelle. Photo via Mosaic Manufacturing