This is a guest post in our series looking at the future of 3D Printing. To celebrate 5 years of reporting on the 3D printing industry, we’ve invited industry leaders and 3D printing experts to give us their perspective and predictions for the next 5 years and insight into trends in additive manufacturing.

Briana Yarbrough is a Chief Marketing Officer and Content Developer at AET Labs, a value-added distributor of technical training tools for educators in New England, USA. As a mother of a vocational technical school student, Briana is passionate about the role of technology in helping to drive forward a culture of innovation in our schools. A maker culture enthusiast with a love for ceramics & clay work she is interested in how 3D printing technology can assist not just engineers, but artists in their craft.

3D Printing: The next 5 years by Briana Yarbrough

Where Industry and Education Intersect

As we speak, the lines between industry and education are being blurred, forming a symbiotic relationship. Gone are the days of learning by rote and prepping the majority of students to continue for a “liberal arts” degree. Problem-based learning and design thinking have become today’s bywords for forward-thinking education institutions. We are realizing how crucial it is to foster “life-ready,” real-world skills in the youngest of children. The type of skills they will need for future jobs in an Industry 4.0 economy — whatever those jobs may evolve into in this rapidly changing world.

Students, themselves, are driving this change. At an increasingly young age, they are learning to code and develop marketable apps, launching their own businesses via Kickstarter, and becoming savvy to the modern reality that anyone with an idea can feasibly design it, make it and bring it to market with digital fabrication technology.

Where does 3D printing fit into all of this, and how will it factor in to changes we see in the next 5 years?

SAT’s and what students KNOW are a receding part of the equation. The question when students graduate from high school and university is what can you DO? The only way to quantify that is with tangible evidence. With the advent of the desktop computer, graphic designers and writers could feasibly come up with a professional looking body of work using digital software. Overhead was suddenly low, and the technology necessary for creating polished, market-ready pieces became widely accessible. Speaking from experience, a well-rounded, professional-level portfolio was requisite in landing an internship or starting a graphic design position after college.

Fast forward 5 years: In order to gain acceptance to college, land an internship or apprenticeship, or first job in a STEM field, employers and higher education will come to expect that students have professional level prototypes and an understanding of how to bring an idea through the design process, from conception to product. Digital fabrication tech and 3D printing in particular, is the catalyst to making this the norm.

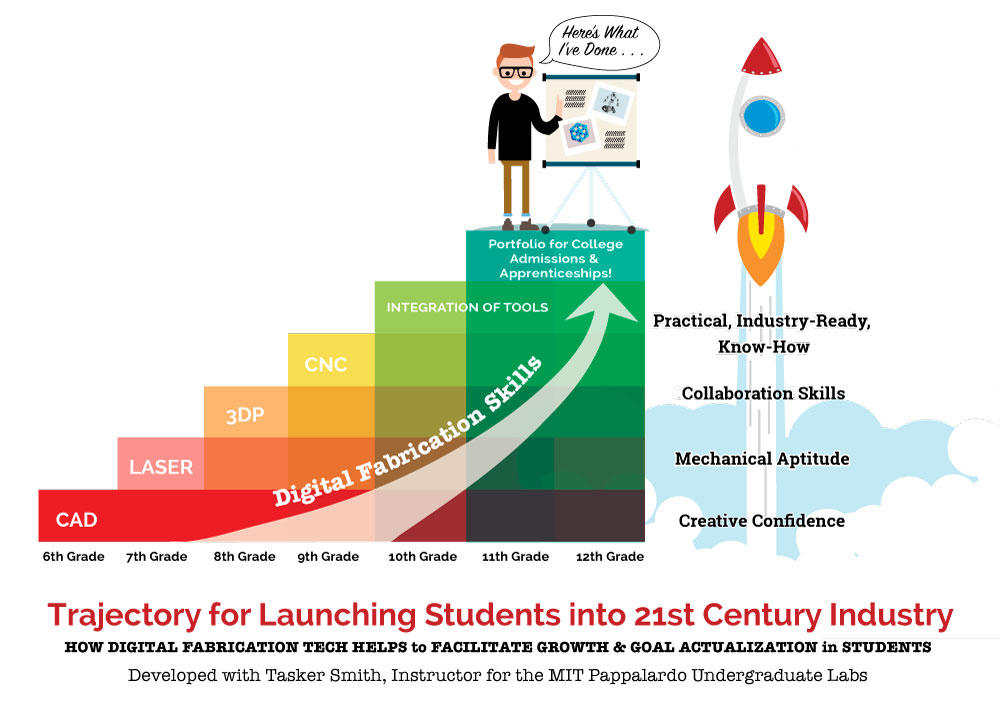

MIT’s Pappalardo Undergraduate lab is a space where students have the opportunity to hone their engineering skills and develop a high-caliber portfolio. In this hub for digital fabrication and innovation, technical instructor Tasker Smith mentors students in the practical use of digital fabrication technologies and the process of iterative prototype development. Smith says, “When applying to competitive schools, it is essential for students to differentiate themselves from the field of high achievers. One way to do this is with a “maker portfolio”: a document that showcases great project work. A good maker portfolio will tell a story about an applicant – and will simultaneously demonstrate personality, technical aptitude and tenacity.”

Access to high quality 3D Printers in the lab factors in significantly to this process, allowing students to iterate their designs rapidly and inexpensively. Smith’s advice for students looking for an engineering position? “A picture may be worth 1000 words, but a model is worth 1000 pictures. I always recommend bringing parts to show and tell on interviews.”

With 3D Printing, Partnerships Between Industry & Education are Mutually Beneficial

The very same 3D Printers used by future employers in Fortune 500 manufacturing companies, will quickly become de riguer technical equipment in schools worldwide over the next few years, just as computer labs and desktop inkjet printers did throughout the 1980’s. With the aid of 3D printing technology, as well as other readily available digital fabrication tools, industry and education will forge a stronger, more mutually beneficial relationship in the next 5 years. Students with fresh skills and minds which “think in 3D” will be given a chance to collaborate on real-world solutions by forward-thinking manufacturers.

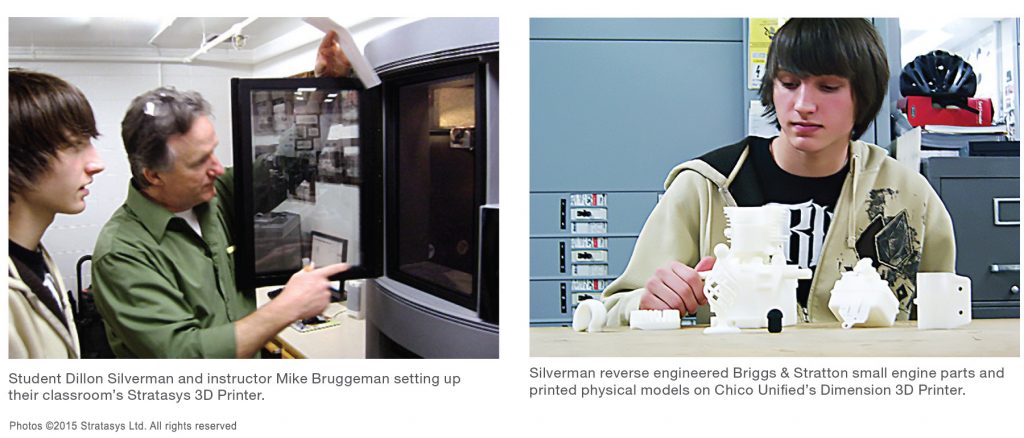

This is being tested out in model programs such as the Chico Unified School District in Northern California, where instructors Mike Bruggemann and fellow instructor Tom Phelan teach nearly 500 students a year in their industrial technology courses. Currently the most popular elective program in the district, it runs in conjunction with regional occupational programs (ROP) in CAD drafting and architecture for juniors and seniors.

Over the past few years the program has been met with support from the outdoor company Klean Kanteen, and many other local entrepreneurs and manufacturers. According the white paper “Six Steps To Building ROI Into Your Curriculum” published by Stratasys, Bruggemann estimates that his students have saved companies who have utilized the program’s CAD and 3D printing services “thousands” in prototyping costs.

One example of this is the collaboration between Westside Research in neighboring Orland, CA and the students at Chico to develop and prototype automotive gear. Owner Tim Dexter, supports the students weekly in a classroom setting, helping them to improve their engineering skills by learning how to research and rework 3D parts to improve functionality, look, and safety. The confidence gained from having the ability to 3D print at their fingertips is priceless. Bruggemann explains that when his students go to an interview related to their ROP work, they take a laptop computer and share their digital portfolios showcasing tangible evidence of their past projects. “Business owners see that, they go ‘that’s impressive.’ They like that a lot,” says the trailblazing teacher.

At AET Labs we are seeing firsthand how 3D printing is being embraced by school districts at all levels in the New England region, with spectacular results. We’re heartened to see how grant initiatives have made it possible for more schools to integrate this technology. Hearing from instructors who are incorporating 3D printing in their classes in meaningful ways inspires us, and we’re thrilled to be along for this exciting ride in the next 5 years!

This is a guest post in our series looking at the future of 3D Printing, if you’d like to participate in this series then contact us for more information.

For more insights into the 3D printing industry, sign up to our newsletter and follow our active social media channels. Let us know your thoughts about this perspective on the future of 3D printing in the comments below.

More information about AET Labs is available here.