This edition of Sliced, the 3D Printing Industry news digest, focuses on the latest developments from the international additive manufacturing show Formnext in Frankfurt, Germany.

Innovations in additive manufacturing hardware

With Formnext in full swing, a plethora of 3D printing hardware has been showcased for the first time. WASP, the Italian manufacturer behind DeltaWASP 3D printers, has unveiled its new series of industrial 3D printers with the Industrial Line 4.0.

With a focus on material versatility and ease of use, the Industrial Line 4.0 features a new user interface which will be adopted across the entire WASP 3D printer line, onboard video tutorial guides, a live-view camera and Wi-Fi module for remote print inspection, as well as a Multicore automatic extruder recognition system.

This system recognizes particular extruders mounted on the printer and automatically adjusts the setting. Furthermore, an Auto calibration system works with this function. The industrial Line 4.0 also allows a printing Via Usb. The Industrial Line 4.0 can be found in Hall 3.0, stand H48.

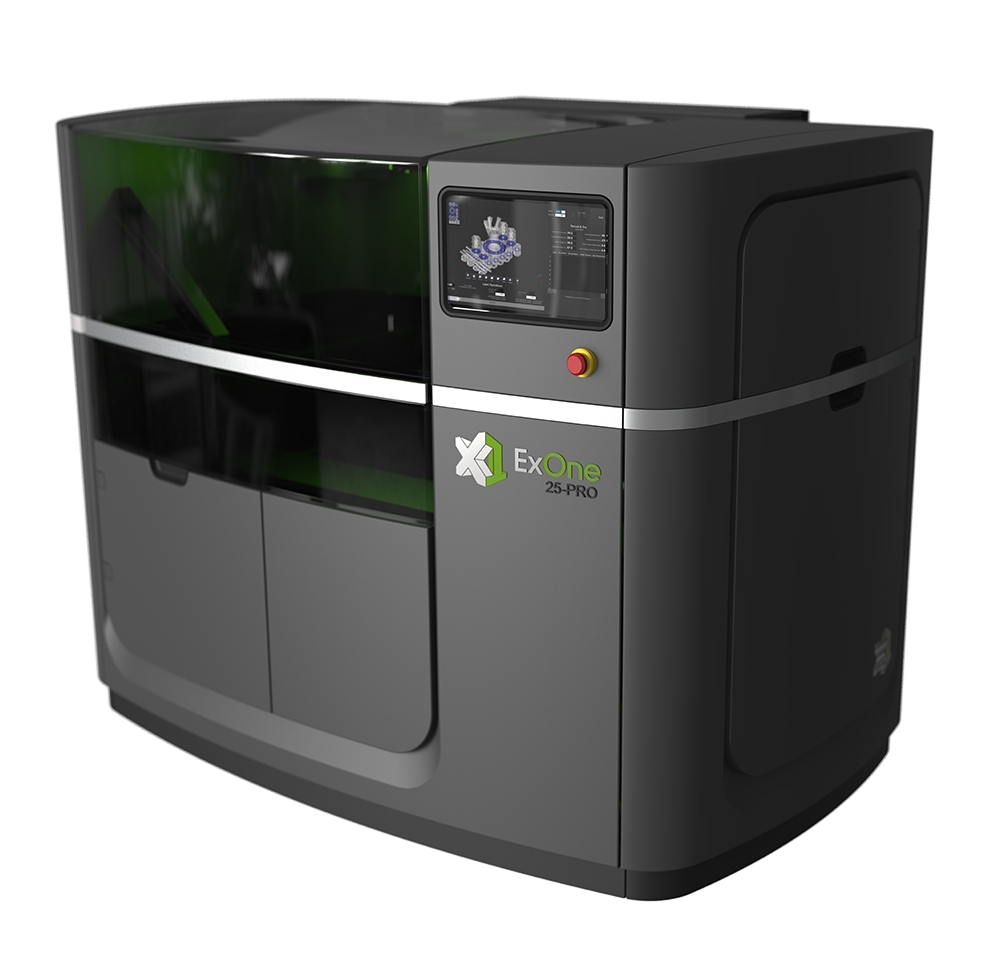

ExOne, a global provider of binder jetting 3D printing systems, services, and materials, has announced the release of its latest system, the X1 25PRO.

“Our X1 25PRO is the first of two machines that we are introducing by the end of the first half of 2019, utilizing our state-of-the-art patent-pending MIM powder processing machine technologies,” said Rick Lucas, CTO of ExOne. “We believe these new production machines will be the most flexible and highest performing binder jetting machines in the market.”

ExOne is currently taking orders for the X1 25PRO system. Formnext visitors can find ExOne in Hall 3.0, stand F19. The 3D printer will be showcased at the RAPID + TCT show in Detroit on next year.

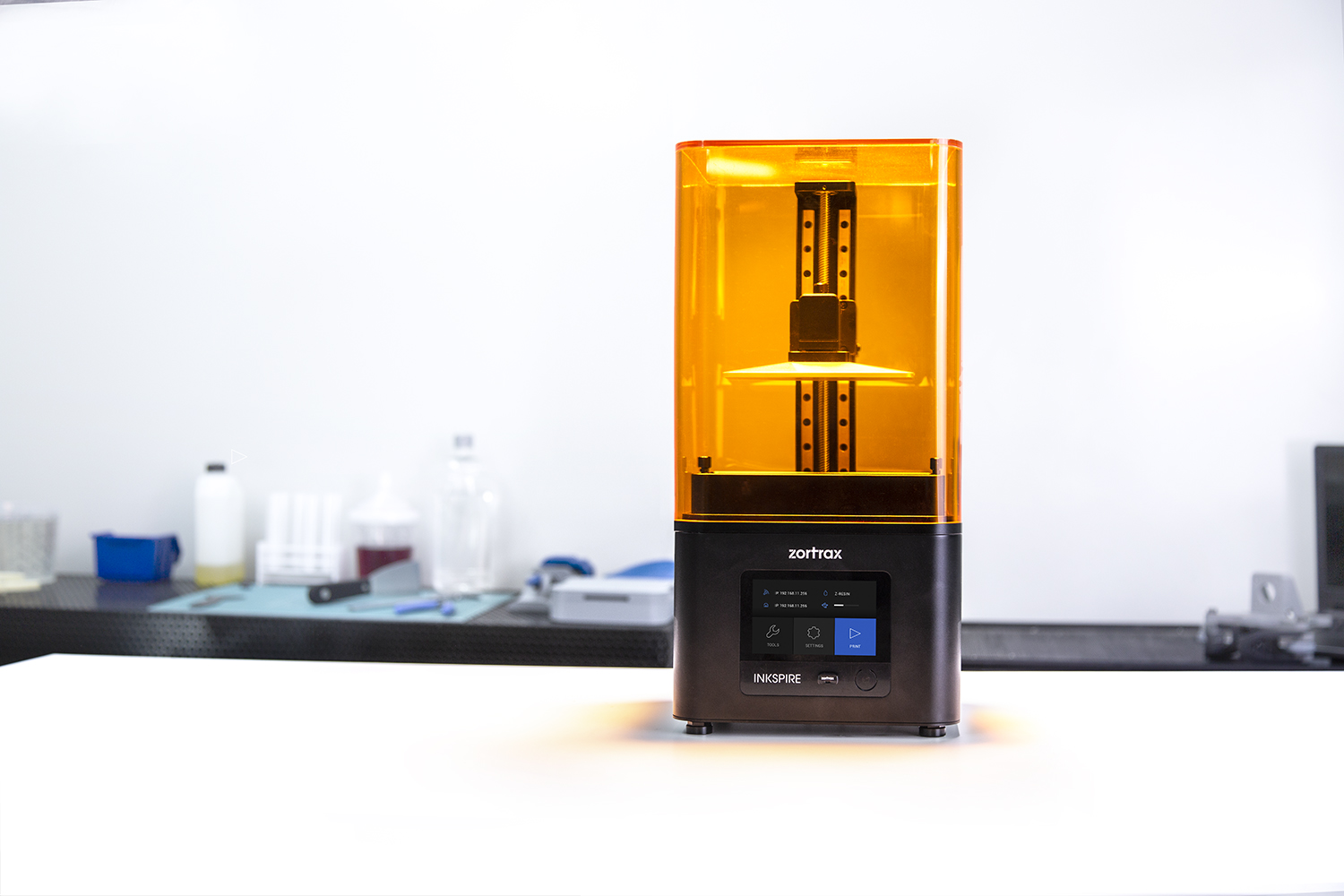

Zortrax, the Polish manufacturer of the popular quality M200 3D Printer, has announced that its latest resin UV LCD 3D printer, the Zortrax Inkspire, is now available for purchase at a cost of $1,990. Zortrax is located in Hall 3.1, stand A81.

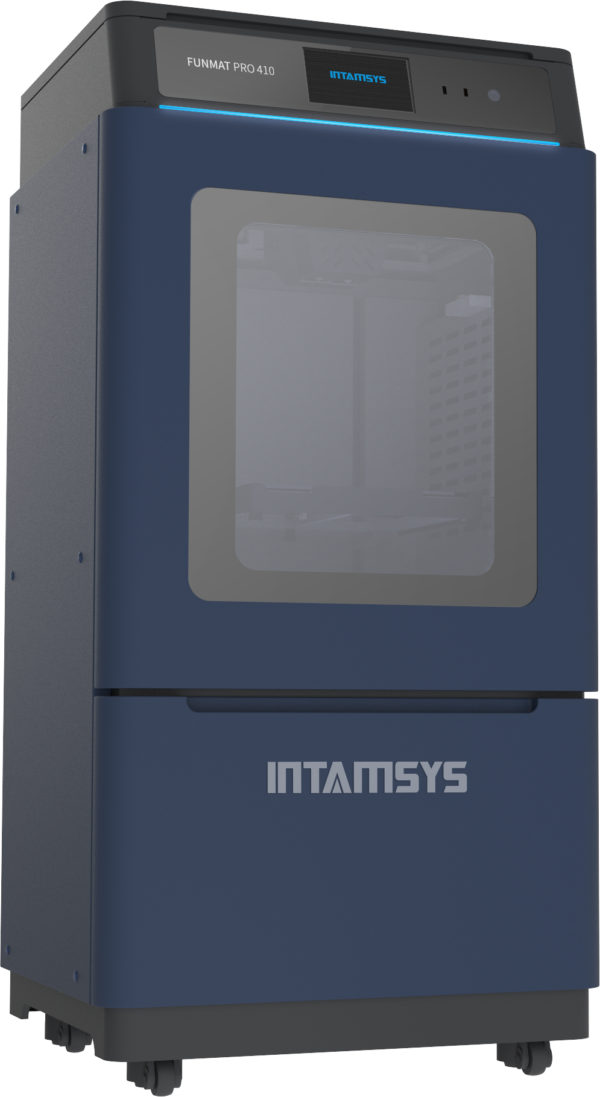

INTAMSYS, a manufacturer of 3D printer for engineering-grade polymers, has released its latest printer, the FUNMAT PRO 410. The dual nozzle printer has a large build chamber measuring 30 x 30 x 40 cm. And with a maximum hotend temperature reaching 450°C, it can print high-temperature plastics such as PEEK, PEKK, ULTEM, and PEI. The FUNMAT PRO 410 is available to see at Formnext 2018, Hall 3.1, Stand 20.

ViscoTec, a German additive manufacturing technologies, is also debuting its two new printheads for the processing of viscous fluids and pastes in 3D printing – The 2-component print head Vipro-HEAD 3/3 and Vipro-HEAD 5. The new printheads can be seen at Hall 3.0, Stand H54.

New materials at Formnext

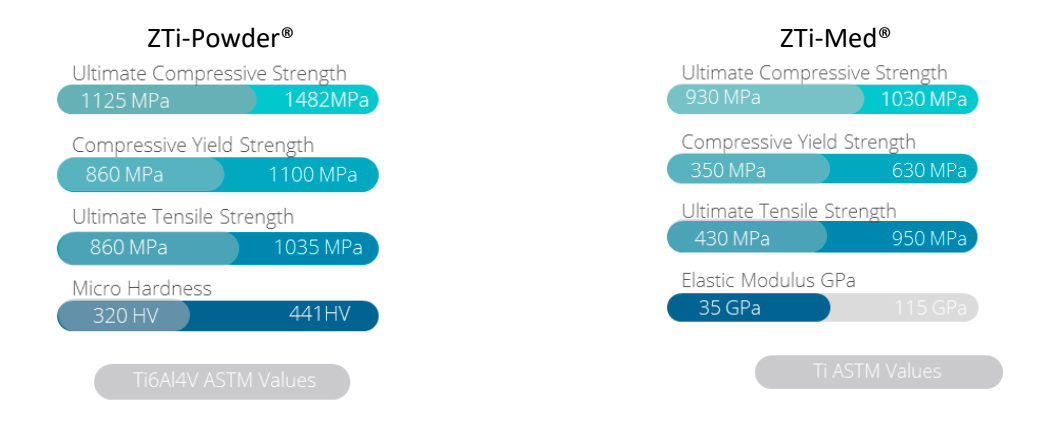

France’s Z3DFAB, an industrial metal 3D printing specialist, has announced the availability of its Nano-Structured Titanium printable powder enriched by 1% Nano Zirconium, to accelerate metal additive manufacturing. The ZTi-Powder and ZTi-Med ranges provide improved characteristics than standard Ti6Al4V, an alpha-beta titanium alloy.

“The ZTi Family is here to replace the old Titanium and bring new enhance characteristics. A family of advanced material specifically designed for AM,” explained Madjid Djemaï CEO of Z3DLAB.

“We are pleased to make available the 1% enhanced Nano-ceramic, with better results to what we obtained back in 2015 with 5%.”This will reduce resistance to change to its minimum and facilitate rapid adoption by both the medical and the industry.”

Z3DLAB and the ZTi range of powders can be found in Hall 3.1 booth D48.

ACEO, of Munich-based chemical group WACKER, is presenting its new silicone rubber materials for additive manufacturing. The new silicone rubber products can serve temperatures of up to 200°C and offer electrical resistance of 10 Ω cm or higher. These materials can be located in Hall 3.1, stand A89.

“3D printing with the new electrically conductive ACEO Silicone enables new-to-the-world applications that could not be implemented until now, especially in modern medical or functional automotive parts”, explained Bernd Pachaly, Head of the ACEO 3D printing project at WACKER.

“We added this new silicone option to our portfolio specifically to address unmet needs and to go beyond conventional solutions”.

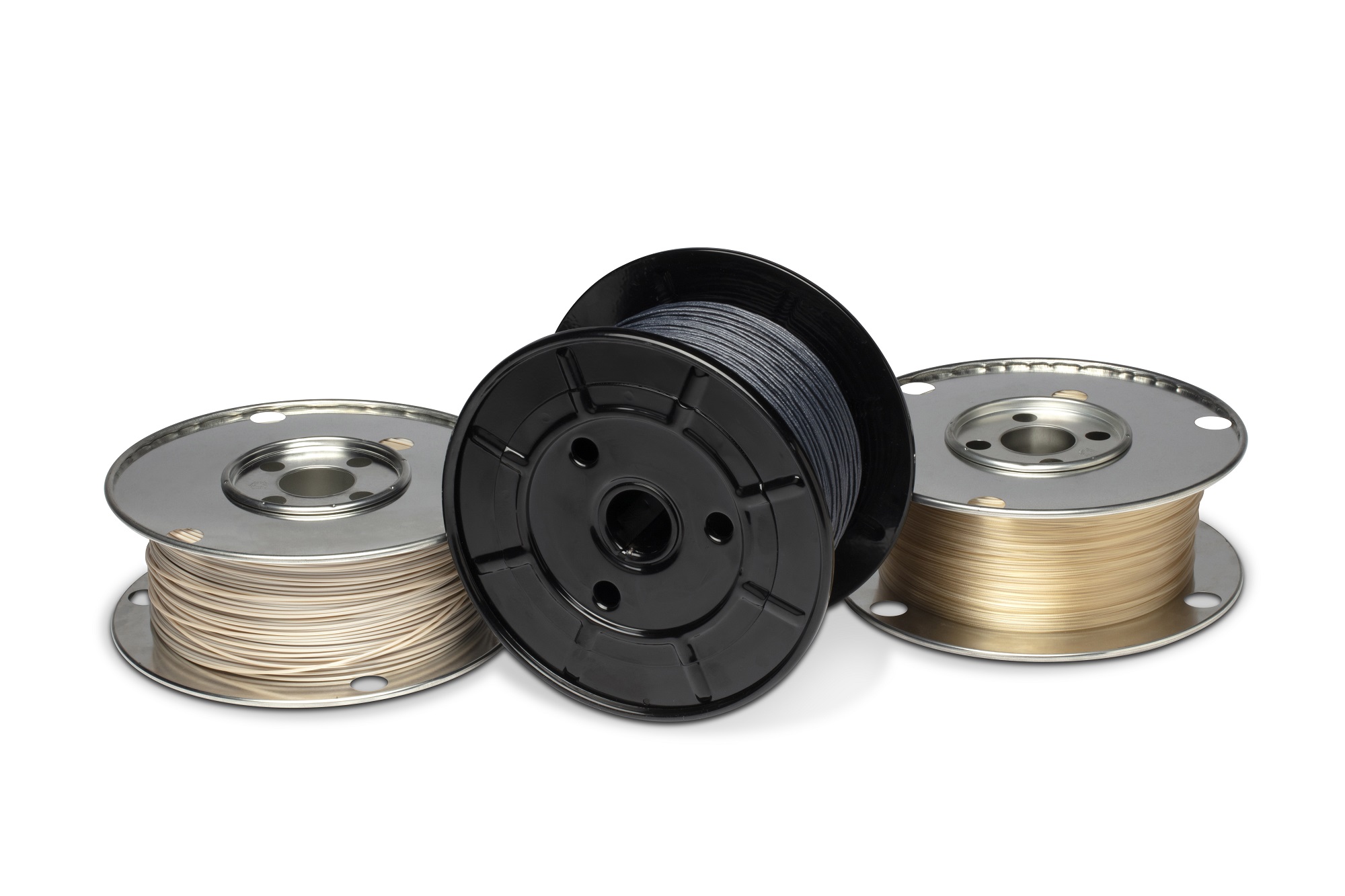

The Dow Chemical Company (Dow) has launched its new EVOLV3D Olefin Block Copolymer (OBC) printing filament for the production of lightweight, durable, and removable parts. Dow currently has technical experts on hand this to discuss the sustainability and performance benefits of EVOLV3D OBC and the EVOLV3D platform in Hall 3.1, Booth D40.

Furthermore, Royal DSM, a Global health, nutrition, and materials company, has launched two new materials designed for 3D printed automotive structural parts. Somos PerFORM Reflect and thermoplastic copolyester Arnitel ID2060 HT, are manufactured for wind tunnel testing with Particle Imaging Velocimetry(PIV). Formnext visitors can view the latest DSM materials in Hall 3.0, E01.

Solvay, a Belgian manufacturer of advanced materials for 3D printing, has released two medical grade filaments, the KetaSpire, a 10% carbon fiber reinforced PEEK material, and the Radel PPSU. Both materials are for limited contact applications i.e. less than 24 hours bodily or tissue contact. Christophe Schramm, Additive Manufacturing Business Manager at Solvay’s Specialty Polymers Global Business Unit (GBU) explained:

“The healthcare industry is quickly emerging as a leading market to benefit from AM technology which makes customized parts for single use or low volumes possible […] However, there is still a very limited choice of high-performance filaments that meet the stringent regulatory requirements in healthcare and this is the gap we want to close with our new selection of medical grade products.”

Solvay is present at Hall 3.1-A79.

Software innovations

Siemens, an award-winning German conglomerate, has unveiled the Simcenter 3D Additive Manufacturing Build Process Simulation, a new integrated software solution which simulates the powder-based laser application process to enable ‘first time right’ prints.

As part of its Digital Enterprise portfolio, “Industrialize Additive Manufacturing,” the company aims to represent a digital twin of the entire value chain, from design and engineering through simulation and production, to machine networking. Siemens’ Digital Enterprise portfolio is displayed in Hall 3.0, booth E50.

DyeMansion, a German post-production solutions provider, has introduced the VaporFuse Surfacing (VFS) technology, a post-production method to rival injection molding surface finish. The VFS produces a soft and glossy finish and can be used on a range of materials including TPU and other soft materials. The new method will be integrated into DyeMansion’s Print-to-Product workflow.Dr. Alena Folger, DyeMansion’s R&D Chemist explained:

“During the process, the surface is dissolved by condensed vapor. Thus, the polymer chains have a sufficiently high mobility and rearrange at the surface. The overall surface area and the surface energy is reduced. Concurrently, the part is smoothed. Upon removing the solvent, the polymer hardens again.”

DyeMansion is presenting the VaporFuse technology at formnext 2018, 3.1-G61.

ESI Group, a virtual prototyping software and services provider, has launched it additive manufacturing solution. The software is capable of identifying manufacturing defects and providing diagnostic reports, and computational models. The software tools are integrated into a platform called Integrated Computational Material Engineering (ICME): ESI Additive Manufacturing.

Dr. Jean Sreng, Business Development Manager for ESI Additive Manufacturing, commented, “To achieve manufacturing excellence in Additive Manufacturing, engineers must first understand and control the complex relationship between part design, 3D printing processes, and material quality. This know-how is essential to engage in process qualification.”

ESI can be found at Hall 3.0, Stand J49.

Formenext Business announcements

DMG MORI, a German manufacturer of cutting machine tools and CNC-controlled machines, has announced plans expand its global presence in metal additive manufacturing by acquiring a 30% stake in INTECH, an India-based developer of 3D printing software. DMG MORI can be found in Hall 3.0, Stand C80 and stand D80.

In other news, America Makes, a U.S. additive manufacturing accelerator based in Youngstown, Ohio, presented the Standardization Roadmap for Additive Manufacturing with the American National Standard Institute (ANSI) at Formnext 2018.

America Makes strives toward rapid development and adoption of additive manufacturing in the US. The Standardization Roadmap was designed with this aim in mind. Its object is to identify the educational and technical gaps in the additive manufacturing industry and seek ways to close them. The Standardization Roadmap is the result of contributions from 320 individuals and 175 public-private institutions and organizations.

FIT Additive Manufacturing Group, a German AM solutions provider, has introduced the SPOD platform (Spare Parts on Demand) to provide on-demand industrial 3D printed spare parts. The SPOD platform will guarantee the availability of obsolete parts at reasonable prices. FIT Additive Manufacturing Group can be visited at Hall 3.1, Stand F88.

Stratasys expands global network

Finally, Stratasys has announced the expansion of its Global Manufacturing Network (GMN). The GMN partners can benefit from Stratasys’ digital factories. Moreover, Stratasys has also stated that its Aircraft Interiors Certification Solution (AICS) will be available to select members.

To its Manufacturing Network, the additive manufacturing giant has now added Italian Tecnologia & Design, South Korea’s Prometheus, Mexico’s Tridi, a 3D printing service bureau, and US-based FATHOM, also a service bureau, providing 3D printing and CNC services.Jeff Hanson, Stratasys’ Director of Global Manufacturing Network said:

“Recognizing the power of our technology to reshore manufacturing across local economies and reduce carbon footprints, we’ve continued to grow this partner ecosystem while consistently proving the value.”

Stratasys can be found at formnext 2018, 3.1-G40.

Stay updated with the latest 3D printing news from Formnext by subscribing to our 3D printing newsletter. You can also follow us on Twitter and Facebook.

Visit our 3D Printing Jobs to start a new career in 3D printing.

Featured image shows the Exhibition floor on day one of Formnext 2018.