In this edition of our 3D printing news digest – Sliced, we feature updates from the European Defence Agency, 3D Systems, Boeing, Carbon, Sculpteo, HP, Mazak, Canada Makes, MakePrintable, EnvisionTEC and Enterprise in Space.

Successful in-flight 3D printing test by European Defence Agency

As 3D Printing Industry previously reported, the European Defence Agency (EDA) is currently assessing the feasibility of 3D printing mid-flight. Now, as part of the European Advanced Airlift Tactics Training Course in Zaragoza, the EDA reports the completion of a successful 30 minute flight with the 3D printing lab. Once landed, the lab was assessed and found to have encountered no issues from the flight.

In the future, the EDA will further demonstrate the potential of 3D printing to support defense capabilities with a dedicated event in Gijón on 12th September.

Former Boeing CTO joins 3D Systems’ Board of Directors

3D Systems continues to expand their expertise in aerospace industry with a further addition to board of directors. The South Carolina company has announced the addition of John J. Tracy, former CTO at aerospace company Boeing.

CEO of 3D Systems, Vyomesh Joshi (VJ) explains the company’s current focus in an interview with 3D Printing Industry earlier this year. Speaking about this announcement, President and CEO, Joshi says,

We are a technology company focused on key verticals and the addition of Dr Tracy to our Board reinforces our commitment to enhance management and the Board in line with our customer centric strategy to drive profitable growth through focused execution. We expect that his invaluable experience and deep knowledge of technology and aerospace will be a valuable addition to our Board.

Carbon receives flammability certification

Californian 3D printing company Carbon has announced it has received UL 94 HB flammability classification for their Rigid Polyurethane 70 (RPU 70) resin. According to Carbon, as a result the resin “is the first UV printable material for additive manufacturing to receive the UL 94 HB flammability classification.”

With this certification, Carbon expects its users to be able to extend the use of RPU 70 to create parts that require flammability resistance. The certification was carried out by UL Performance Materials. UL VP & GM Mette Pederson said,

With this certification, Carbon can now offer their tested and certified material to manufacturers who are focusing on 3D printed components and parts for their production applications.

Sculpteo announces offering of HP Multi Jet Fusion 3D printer services

French 3D printing bureau, Sculpteo has announced it will begin offering services using the HP Multi Jet Fusion 3D printer later this month. Sculpteo is now part of a select group of companies and bureau with access to HP’s technology.

Clément Moreau, co-founder of Sculpteo explains the significance since, “in digital manufacturing, speed is of the essence. With HP, Sculpteo continues to innovate to offer a factory increasingly affordable, fast and precise.”

3D Printing Industry recently visited HP’s Corvallis site in Oregon as the company announced the launch of a material development kit to encourage expansion of the range of 3D printable materials available to the Multi Jet Fusion 3D printer.

Mazak joins Canada Makes

Mazak, who produce additive, subtractive and hybrid manufacturing machines has become the latest partner of Canada Makes. The Canadian initiative is intended to accelerate industry adoption of additive manufacturing technology.

Ray Buxton, General Manager of Mazak Corporation Canada spoke about the partnership, “as a leader in Additive / Subtractive Direct Energy Deposition technology, we strive to be at the forefront of this manufacturing evolution.” Previously, Canada Makes has supported the industry with investment into micro metal additive manufacturing.

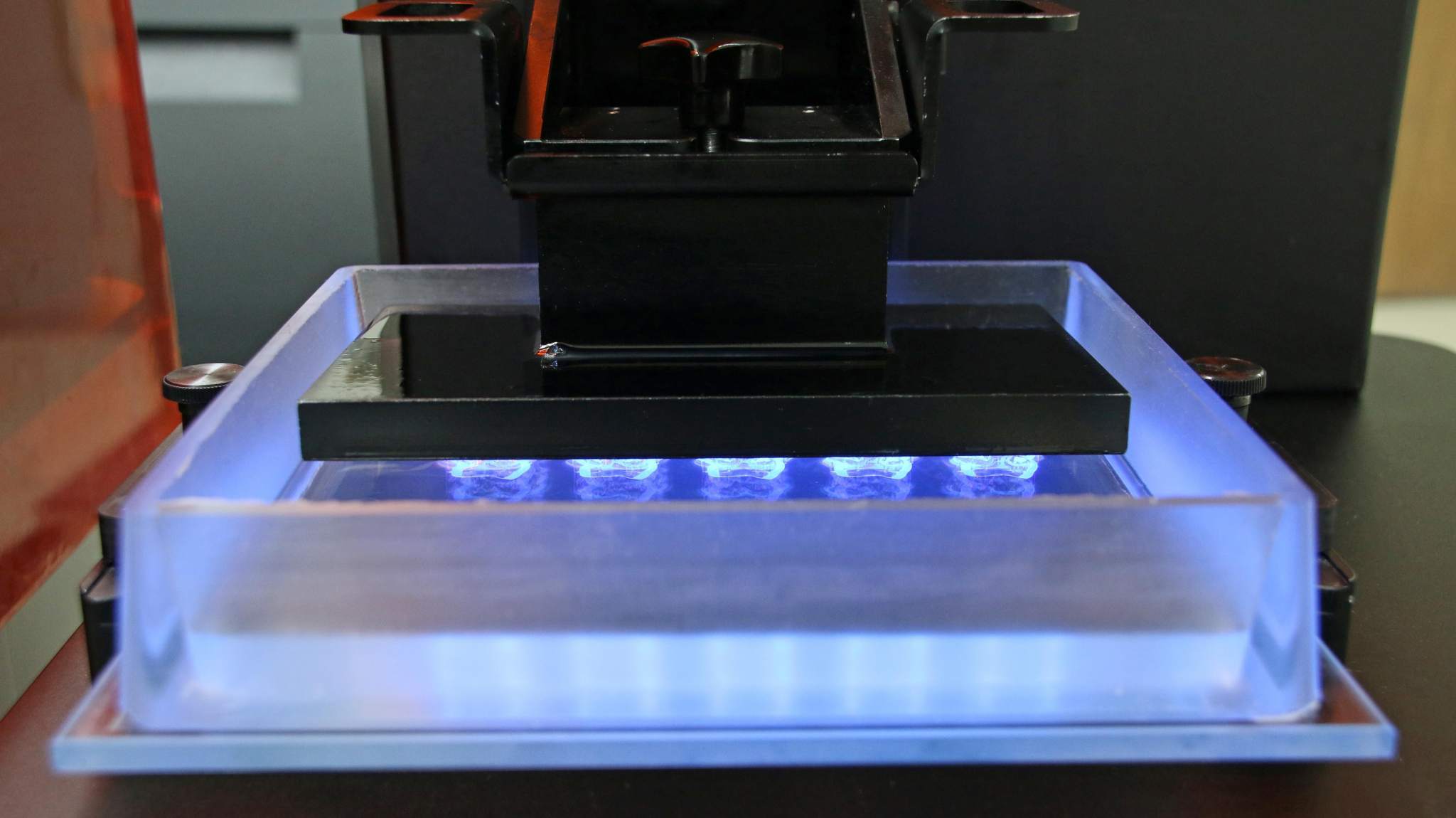

EnvisionTEC launches new disposable material tray

Michigan-based EnvisionTEC has announced the launch of a cost-saving disposable material tray for its line of resin-based 3D printers. According to CEO Al Siblani, “this new material tray system makes using EnvisionTEC desktop 3D printers even easier and more affordable.” The tray is expected to last 3-4 months with regular use and is intended for the Micro and Vida lines of 3D printers.

MakePrintable update

Cloud based software producer MakePrintable has announced that repairs are now free and unlimited. The software analyzes and fixes 3D printed models. MakePrintable now base subscriptions on the amount of downloads rather than number of repairs.

Also, MakePrintable has announced MakePrintable’s Labs which allows users to try beta tests of new repair algorithms and other “cool stuff.” Lastly, MakePrintable has introduced a new mesh repair mode called Mammoth GPU which it is currently encouraging users to test. 3D Printing Industry took a closer look at the San Francisco company’s software recently.

Print the Future winner announced

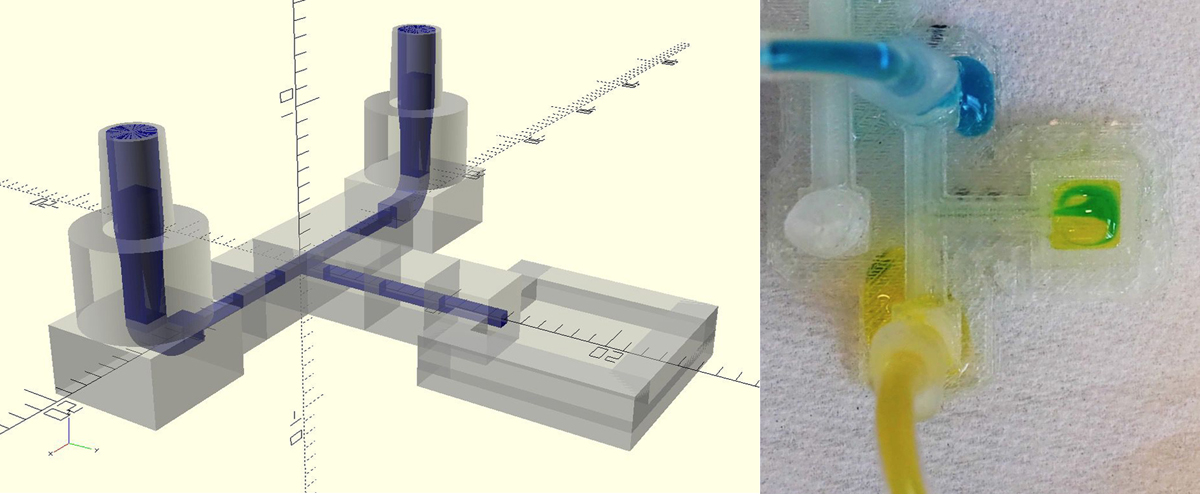

The winner of the Enterprise in Space (EIS), Print the Future competition has been announced. University of Pennsylvania undergraduate students Adam Zachar, Laura Gao and Jaimie Carlson, won the competition for their microfluidic modules. Known as Team ProtoFluidics, the group created 3D printable modules which could be fabricated on the ISS’s Made in Space 3D printer and enable microfluidic experimentation.

For all the latest 3D printing news, subscribe to the most widely read newsletter in the 3D printing industry, follow us on twitter and like us on Facebook.

Featured image shows Sliced logo over image of microfluidic designs from Team ProtoFluidics.