Welcome to CrAMmed, the first edition of our 3D printing digest based on the latest academic additive manufacturing research.

Today, CrAMmed details the latest applications for 3D printed molds from the Ming Chi University of Technology; 3D printed microfluidic circuitry for medical devices and pharmaceuticals from the University of Maryland; as well as 3D printed medicine for young adults from St. John’s University.

Investigations integrating additive manufacturing in various sectors can also be found from academic institutions such as the University of Grenoble, Delft University of Technology (TU Delft), and the Institute for Technology and Innovation Management (TIM) RWTH Aachen University.

Materials & 3D printed injection molds

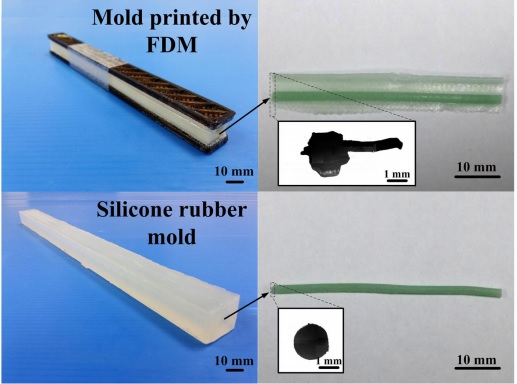

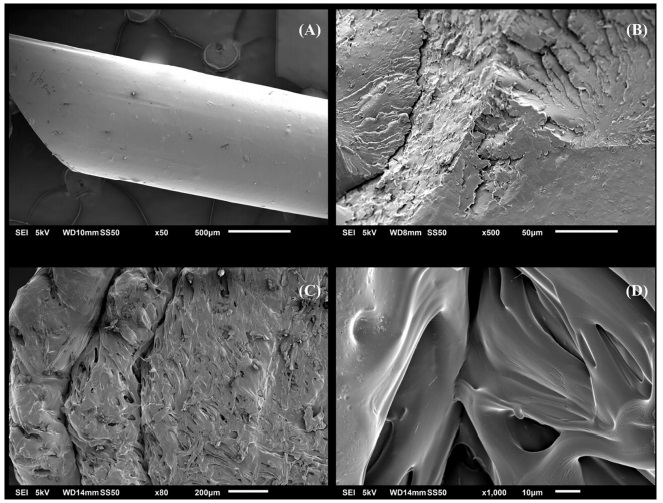

Researchers from the Department of Mechanical Engineering (ME) at Ming Chi University of Technology (MCUT) in Taiwan have created a wax filament with improved mechanical properties using 3D printed injection molds and dies.

According to the study, cooling time in an injection molding process consumes an estimated 60- 80% of the entire molding cycle. However, molds with conformal cooling channels can promote temperature uniformity in the plastic materials, improve part quality, and shorten cycle times.

Considering this, the MCUT team used a Stratasys uPrint 3D printer and ABS to create a mold with easy removal that would produce a low-cost and low-melting long wax filament. From this mold, a silicone injection mold was created to fabricate the filament.

The researchers found that from both 3D printed and conventional molds, wax filament fabricated from the silicon molds displayed improved surface-quality, high tensile strength, and high bending curvature. Nonetheless, the team states that 3D printed molds “are very practical and provides the greatest application potential in the precision rapid tooling industry.”

“Development and application of a conformal cooling channel with easy removal and smooth surfaces,” is published in Springer Link. The research paper is led by Professor Chil-Chyuan Kuo.

Engineers from Nazarbayev University in Kazakhstan have explored the ability to predict micromechanics in composite 3D printing materials. As defined by the researchers, “micromechanics studies the relationship between the macroscopic engineering parameters and the microscopic distribution of material constituent.”

Using the Monte Carlo Simulation (MCS) in the MATLAB program, the engineers created an algorithm that can analyze the properties of the composites. This investigation aimed to create a process where such materials can be analyzed for optimal use in 3D printing.

The researchers found that their algorithm was more effective than the alternative mathematical method, Finite Element Analysis (FEA).

“Composite Materials Property Determination by Rule of Mixture and Monte Carlo Simulation” is IEEE Xplore. The first author of this research paper is an assistant researcher, Gaziz Yerbolat.

Snehal Sharad Kamble, a technical officer at the Indian paint company, Kansai Nerolac Paints Ltd has discussed the potential for chitin, a natural amino polysaccharide (polymeric carbohydrate molecules) for 3D bioprinting and food preservation.

“Chitin and chitosan polymer: A review of recent advances and prospective applications” is published in Chemarc.

Furthermore, an international review paper published in Springer Link has assessed the use of fiber reinforced additive manufacturing (FRAM)-based components in a study entitled, “The trends and challenges of fiber reinforced additive manufacturing.”

The first named author of this paper is Ismail Fidan, Professor of Manufacturing Technology at Tennessee Tech University.

3D printing and nanoelectronics

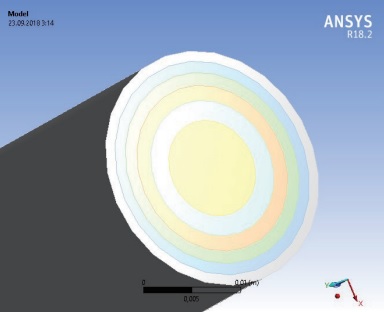

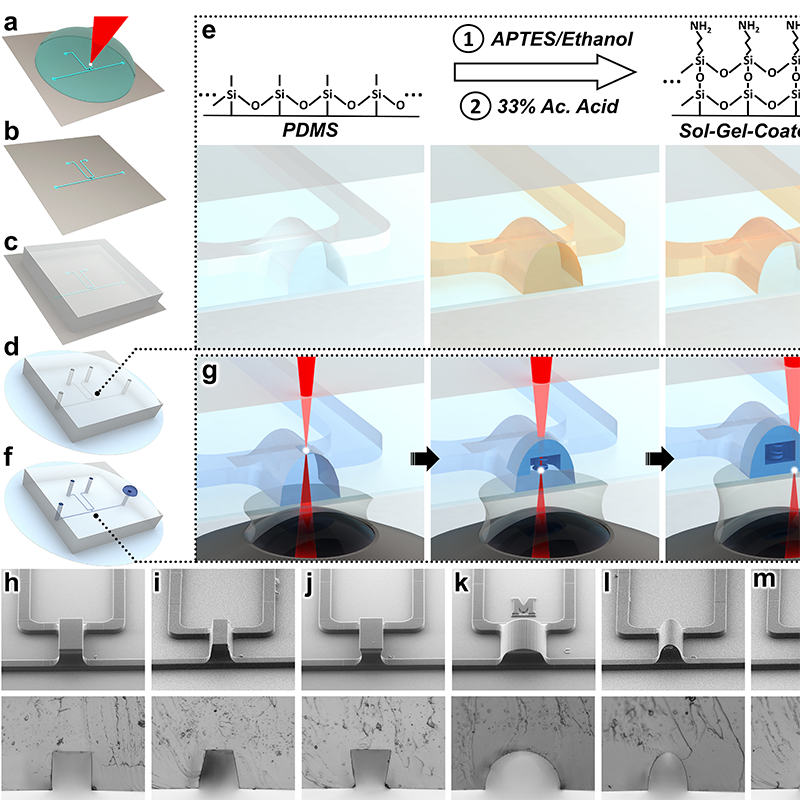

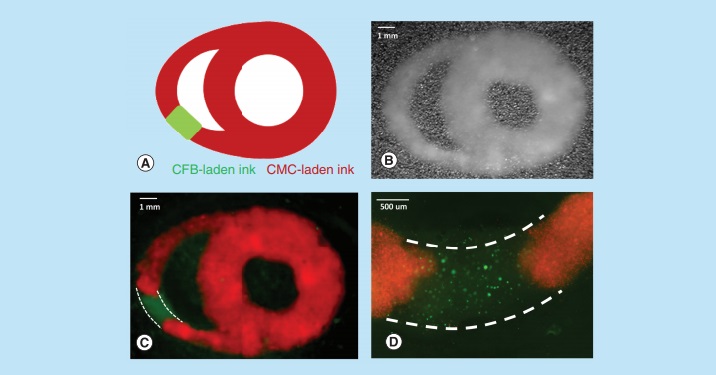

Researchers from the University of Maryland (UMD) have created what is said to be the first 3D printed fluid circuit element “so tiny that 10 could rest on the width of a human hair.” The diode enables fluids to move in a single direction, which is required for implantable devices that release therapies directly into the body.

“Just as shrinking electric circuits revolutionized the field of electronics, the ability to dramatically reduce the size of 3D printed microfluidic circuitry sets the stage for a new era in fields like pharmaceutical screening, medical diagnostics, and microrobotics,” said Ryan Sochol, an assistant professor in mechanical engineering and bioengineering at UMD’s A. James Clark School of Engineering.

Sochol, along with graduate students Andrew Lamont and Abdullah Alsharhan, outlined their strategy in the paper “New 3D nanoprinting strategy opens door to revolution in medicine, robotics” published in Nature.

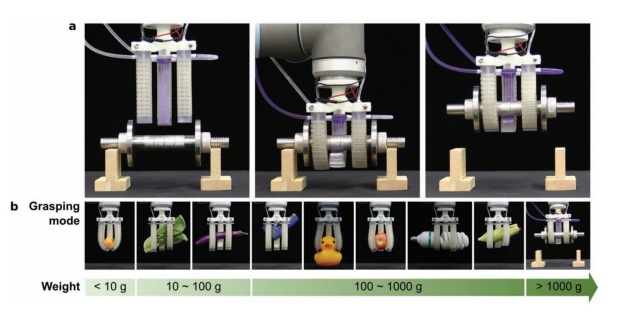

Engineers from the Singapore University of Technology and Design (SUTD) and Shanghai Jiao Tong University in China (SJTU) have 3D printed a fast-response, stiffness tunable (FRST) soft actuator which can complete a softening-stiffening cycle within 32 seconds.

“We combine a commercial inkjet multimaterial 3D printing technology with the direct-ink writing approach to fabricate our fully printed FRST actuator,” said Assistant Professor Qi (Kevin) Ge from SUTD’s Science and Math Cluster, who is one of the co-leaders of this project.

“The stiffness tunability is provided by an embedded SMP [shape memory polymer] layer, and the fast response is enabled by embedded heating and cooling elements.”

In its stiff state, the FRST actuator can perform load-carrying tasks. A robotic gripper was integrated with three FRST actuators. The gripper was able to lift weights spanning from less than 10g to up to 1.5 kg. The researchers are now exploring the mechanical and thermal-electrical behaviors of the FRST actuator for additional industrial applications.

“Multimaterial 3D printing used to develop fast response stiffness-tunable soft actuator” is published in Advanced Functional Materials.

Researchers from the University of Grenoble, France, have proposed a new thermal simulation method to determine energy input in beam trajectories in powder bed additive manufacturing. According to the study, “Controlling thermal history is a key factor for the success of an additive manufacturing operation.”

“Thermal history depends on manufacturing strategies i.e., beam path and energy input. Energy input and beam path, are determined by either very simple models at the machine site or complex and time-consuming finite element models.”

Using an abacus based simulation, the team found that the precision of the results regarding simulated temperature was 4.48% higher than by the finite element method.

“Rapid Thermal Simulation of Powder Bed Additive Manufacturing” is published in IEEE Xplore. Frédéric Vignat is the first author of this research paper.

Similarly, a team from Germany’s Institute for Technology and Innovation Management (TIM) RWTH Aachen University, have developed an integrative profitability model for a holistic assessment of Laser-Powder Bed Fusion.

The research, “Introducing a Holistic Profitability Model for Additive Manufacturing: An Analysis of Laser-powder Bed Fusion” is published IEEE Xplore and is led by Frank Piller a professor of technology and innovation management at RWTH Aachen University.

Exploring 3D printing in medicine

Researchers from the Cardiovascular Lab at the George Washington University (GWU) have investigated the effects of gelatin methacryloyl (GelMA) concentration on cardiac myocytes and fibroblasts, which are used to 3D print heart tissue.

The scientists found that cell survival within 3D printed cardiomyocyte-laden GelMA constructs were more sensitive to extruder pressure and GelMA concentrations than within 3D fibroblast-laden GelMA constructs.

“Use of GelMA for 3D printing of cardiac myocytes and fibroblasts” is published Future Medicine. The first author of this study is Priyanka Koti, a Graduate Student at Cornell University and researcher from the Cardiovascular Lab, GWU.

A team from the College of Pharmacy and Health Sciences, St. John’s University in New York, have explored the potential of 3D printing customized minicaplets of baclofen – a medication used to treat spasticity– for the pediatric population.

Using baclofen loaded filaments in FFF additive manufacturing, the researchers found that minicaplets printed in a diamond (fast) infill pattern with 100% infill showed high disintegration time of 38 minutes, compared to linear, sharkfill and hexagonal patterns. The team concluded that “low cost FDM 3D printing technique[s] can be a promising alternative for preparation of dose and release customized pediatric dosage forms.”

“Application of 3D printing technology and quality by design approach for development of age-appropriate pediatric formulation of baclofen” is published in ScienceDirect. Siddhant Palekar, a PhD Student at St. John’s University, led the research.

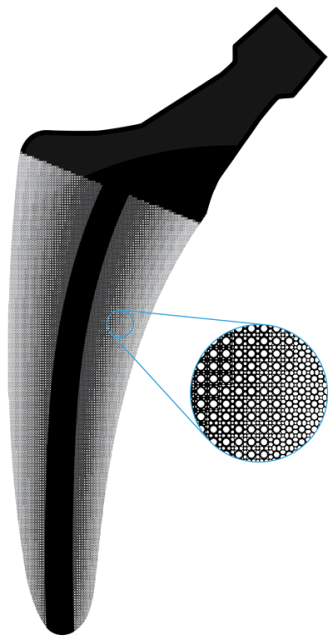

In the research paper “Compatibility in Microstructural Optimization for Additive Manufacturing”, a team from the Delft University of Technology (TU Delft), have sought to optimize the process of 3D printing graded microstructures.

“Microstructures with spatially-varying properties such as trabecular bone are widely seen in nature, the study explains.

“These functionally graded materials possess smoothly changing microstructural topologies that enable excellent micro and macroscale performance. A challenging aspect in the computational design of such materials is ensuring compatibility between adjacent microstructures.”

The research found that by optimizing the mechanical properties of compound cells and individual cells in a 2D design first, microstructures ensures material connectivity for subsequent 3D printing medical processes.

Eric Garner, a PhD researcher at TU Delft is the first author of this research paper.

Researchers from the University of Strathclyde, Glasgow, have combined 3D bioprinting and a robotic-assisted minimally invasive surgical technique to treat cartilage defects. Using a Remote Centre of Motion (RCM) and “viscous material extrusion 3D printing” the scientists believe that this method can be used for focal cartilage defects of the knee.

It was deduced that the RCM mechanism is “feasible with viscous material extrusion 3D printing processes, without a major trade-off in imprint quality.”

“Robotic-assisted 3D bio-printing for repairing bone and cartilage defects through a minimally invasive approach” is published in Strathprint.

Moreover, in the international research paper “Emergence of three dimensional printed cardiac tissue: Opportunities and challenges in cardiovascular diseases” published in Bentham Science, scientists have reviewed the current advancements and future prospects of 3D bioprinting.

The first author of the study is Nitin B. Charbe, a PhD researcher in the Department of Pharmacological Sciences, University of Milan.

3D printed mash potatoes

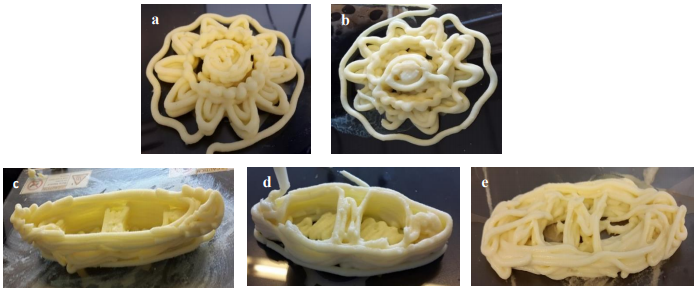

Iman Dankar, a PhD researcher of Agriculture Food technology and Engineering, Polytechnic University of Catalonia, has explored the capabilities of 3D printing mash potatoes with food additives.

“The main purpose of this thesis was to determine and optimize the ideal conditions for best extrusion 3D printing and best-printed end product, by characterizing the physical, chemical, microstructural and rheological properties of the material mixture.”

Dankar found that agar and alginate additives solidified the potato puree, however, glycerol and lecithin had the opposite effect. This research is believed to demonstrate the capabilities of using 3D printing to produce customized food with tailored texture and nutritional content, with minimal waste.

Dankar’s study is entitled, “Study and Characterization of Microstructural and Physio-chemical properties of potato products for 3D Food Printing.”

It’s not too late to nominate academic candidates for the upcoming 3D Printing Industry Awards 2019.

Want the latest 3D printing research? Subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Looking for a fresh start this year? Visit 3D Printing Jobs to commence your career in additive manufacturing.

Featured image shows the CrAMmed logo over packing created from Chitin and chitosan polymers. Photo via Chemarc.