Researchers from the Bristol Robotics Lab (BRL), the University of York, Edinburgh Napier University and the Free University of Amsterdam are developing a 3D printing system that can create autonomous robots for extreme nuclear environments.

Project Autonomous Robot Evolution

Earlier this year, the consortium of researchers commenced the Autonomous Robot Evolution (ARE) four-year project, to explore new design approaches for robotics operating in foreign and extreme environments.

“In a radical new approach we will co-evolve robot bodies and brains in real-time and real-space,” stated Alan Winfield, Professor of Robot Ethics at the University of the West of England which hosts BRL.

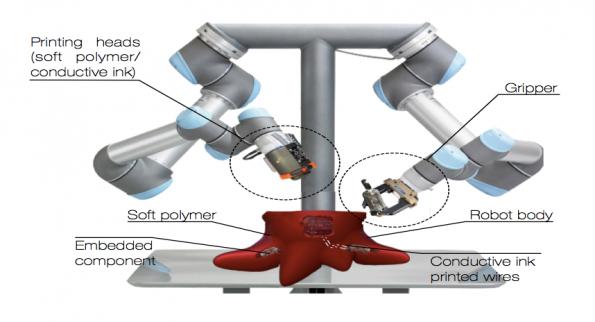

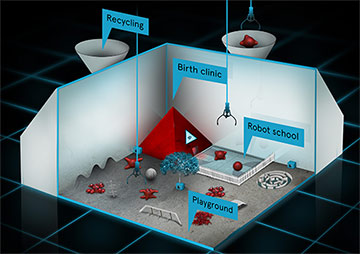

After five years of searching for finances, the ARE project received over £1 million in funding from the Engineering and Physical Sciences Research Council (EPSRC). With this, the BRL has started the development of a purpose-designed 3D printing system, dubbed the ‘birth clinic’, to print small mobile robots.

This process will begin with pre-designed and fabricated electronics, sensing and actuation modules, which are all responsible for robot motor functions. This hardware will be integrated into the 3D printing process to produce a novel hybridized architecture for the robots physical form.

Following this process, the robots will be trained in a ‘nursery’ then fitness tested in specific habitats, that is, a mock nuclear plant, to evaluate behaviours and functionality. Information garnered from this process will then be automatically harnessed to create, or “evolve”, smarter robot designs.

“Evolving real robots is slow and resource hungry,” added Winfield.

“The genomes of the fittest robots will be combined to create the next generation of ‘child’ robots, so that – over successive generations – we will breed new robot designs in a process that mirrors the way farmers have artificially selected new varieties of plants and animals for thousands of years.”

According to Winfield, the ARE researchers are unaware if what the robots they create will look like as the evolutionary process has the potential to form any body shape and structure.

Autonomous technology & 3D printers

Robotic 3D printing technology has streamlined manufacturing in a variety of industries. With little need for human oversight, the University of Nantes (IUT) used its patented cement 3D printing technology to build a house in 54 hours.

Furthermore, Made in Space (MIS), revealed further details on a similar project, entitled “Archinaut“. This project has created a system of technologies that enable orbital fabrication on satellite surfaces using additive manufacturing.

The long-term vision of the ARE project is to also create its own technology enabling automated 3D printed robotics. The researchers believe that this will help in the production of evolutionary autonomous robotic ecosystems able to operate for long periods in challenging and dynamic environments.

The ARE project also includes R&D lab EPFL in Zurich and NASA’s Jet propulsion Lab. Edinburgh Napier University is currently developing software for a hybrid real-virtual process that will allow a testing platform for real and virtual robots.

Catch up with more of the latest 3D printing research projects by subscribing to the 3D Printing Industry newsletter. Also, follow us on Twitter, and like us on Facebook.

Looking for a change of pace? Seeking new talent for your business? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Featured image shows an electrical circuit board. Photo via Global Electrical Services.