September 2017 saw 3D Printing Industry visit the TCT show in Birmingham, UK. This was an opportunity for hardware, materials and software manufacturers to make teaser releases ahead of formnext in November, and it did not disappoint.

In September 3D Printing Industry also visited Taiwan to get the first look at the T3D smartphone powered 3D printer and visit some of the countries leading additive manufacturing enterprises and research centers.

New releases from companies not traditionally associated with the 3D printing industry caught our eye, while our stories about medical applications caught the eye of our readers.

3D Printing Industry exclusives

In September we visited EOS for an exclusive preview of the EOS P 500 laser sintering system. 3D Printing Industry was given an insight into the technology at the company’s Customer and Technology Center in Krailling, Germany. The P 500 is capable of producing double the output of its P 396 predecessor, with a 30% reduction of cost per part.

According to EOS, the new system was developed with a reproducible part quality job-to-job and between machines, automation for Industry 4.0, and material versatility in mind. The P 500 saw its launch at formnext 2017.

3D printing industry also managed to get an early look at the Voxeljet’s High Speed Sintering (HSS) VX2000 system. The HSS technology uses an infrared reactive ink that is polymerized by a sweeping print-arm, and it was invented by Neil Hopkinson at the University of Loughborough in the early 2000s. The VX2000 notably features an open-materials platform.

TCT 2017 and beyond

After visiting XYZPrinting’s home country of Taiwan, TCT 2017 at the National Exhibition Centre (NEC) in Birmingham provided an opportunity to get a second look at the companies full-color da Vinci 3D printer.

The event also brought 3D printers and 3D printing systems, including the Liquid Crystal Maximus 3D printer. Also on display was the SHR3D IT recycling system from 3Devo, and samples (although no 3D printer) produced by the Formlabs Fuse SLS 3D printer.

The Formlabs Fuse marked another trend in the 3D printing industry, that of more affordable SLS 3D printers. Early movers in this space are Sinterit, who in September further dropped the price of their LISA 3D printer. In November, the Natural Robotics VIT desktop SLS 3D printer would complete a successful Kickstarter. The VIT caused much initial excitement, not least for the promise of 3D printing in white nylon. At 3D Printing Industry we are looking forward to seeing samples and of course having the opportunity to test the machine.

3D Printing Industry also visited the National Physical Laboratory (NPL) in London, for the institute’s first Advanced Materials Showcase since becoming a public corporation. Here we saw some of the additive manufacturing and destructive testing that the NPL was conducting, as part of its effort to boost advanced manufacturing in the UK.

Across the Atlantic from these events, the Maker Faire New York 2017 was held at the New York Hall of Science. The Faire featured 3D food printing projects such as 3DigitalCooks, fabrication products from Dremel, and multi-material filaments from FilamentOne.

Under the skin, the readers’ favourite stories

The medical applications of 3D printing made a significant impression with readers and gave us our most-read stories of the month. A 3D printed tibia saved the leg of Australian patient Reuben Lichter. The 3D printed tibia acted as a scaffold to merge existing cells from the body, and will eventually allow the patient to walk again.

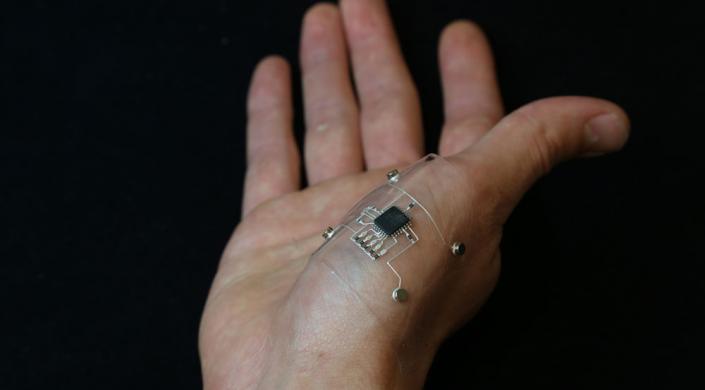

From bones to skin, Harvard researchers used a hybrid 3D printing method combining direct ink writing (DIW) with automated pick and place (P +P) of pre-fabricated components to produce a second electronic skin. Envisioned as having future use in wearables, the researchers 3D printed a flexible strain sensor for the elbow and a foot-sole pressure point reader as a proof-of-concept.

To provide general medical assistance in war, Gaza’s Glia Project continued its work 3D printing stethoscopes and began teaching doctors how to assemble and use 3D printers for essential medical supplies.

3D Printing Industry’s favourites

The city of Chongqing in China decided to check the prevalence of 3D printers within its boundaries by ordering the registration of all additive manufacturing industries. The authorities stated that this action would help keep dangerous and illegal products from the public.

The smartphone market took forays into 3D design and VR in September, with Sony introducing the the 3D Creator app on its Xperia XZ1 smartphone, and Apple’s release of the iPhone X, which features 3D scanning, facial recognition, and augmented reality (AR). While not yet a serious replacement for dedicated software, the progress of major enterprises is always on our radar.

From the palm of the hand to out of this world, 3D printing also continued produce permanent parts for the aeronautical industry. Airbus installed a 3D printed titanium bracket on to its in-service A350 XWB plane, and it will form part of the part of the aircraft pylon, the segment of a plane attaching jet engines to the wings.

Not be put out of orbit, NASA announced that they had successfully complete 30 firing tests on a bi-metallic 3D printed rocket igniter at the Marshall Space Flight Center in Huntsville, Alabama. Essential to the start sequence of a rocket engine, engineers considered it a technological achievement to 3D print and test rocket components made with two different alloys.

Nominations for the second annual 3D Printing Industry Awards are now open. Make your selections now.

For more annual round-ups, subscribe to our free 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Featured image shows the TCT 2017 Logo. Photo by Michael Petch.