The month of October saw a number of AM developments within the aerospace sector including the fundraising for the Terran 1 rocket as well as partnerships accelerating the production of various 3D printed space components. Moreover, major business movements occurred from Lulzbot, EOS, Stratasys, and others.

Aerospace developments

Relativity Space, a Californian 3D printed rocket manufacturer, announced the successful raising of $140 million in funding to develop the company’s Terran 1 rocket, currently scheduled for a test launch by the end of 2020. The company has plans to enter this rocket into commercial service in 2021 with a contract from Canadian communication satellite provider Telesat.

In Australia, Melbourne-based Titomic, the provider of Titomic Kinetic Fusion (TKF) metal 3D printing, partnered with fellow Australian space company Gilmour Space Technologies to produce ‘high-performance’ 3D printed rocket and space components.

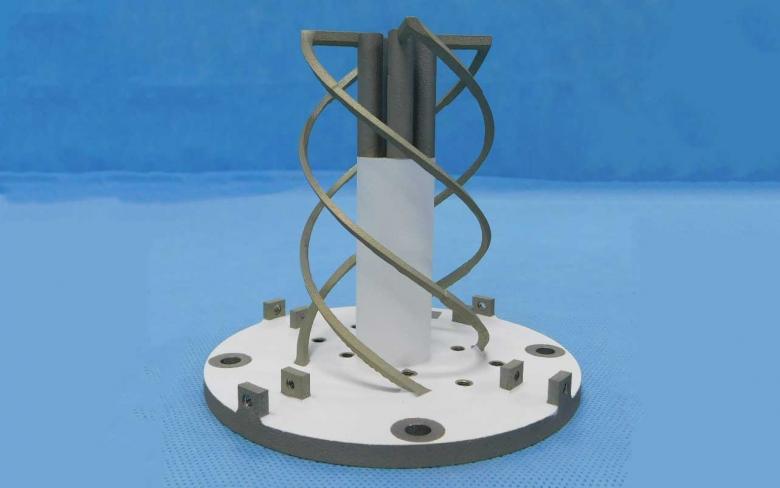

SENER Aeroespacial, the aerospace arm of Spanish engineering and technology group SENER, and the Centre for Advanced Aerospace Technologies also collaborated to develop a 3D printed metal antenna for the European Space Agency’s PROBA-3.

Business movements, new 3D printing systems, Hubs and the MTC3

Leading German 3D printer manufacturer EOS appointed Marie Langer, the daughter of company founder Dr. Hans Langer, as its new CEO, while outgoing CEO Dr. Adrian Keppler takes on a role as managing director.

Across the open-source 3D printing community, desktop 3D printer manufacturer Lulzbot also began battling rumors of its closure after the Colorado-based company made the majority of its staff redundant.

Stratasys launched a new PolyJet system: the J850. Replacing the company’s award-winning J750 3D printer, launched 2016, the machine is reportedly capable at 3D printing at twice the speed and at a “significantly lower cost.”

Elsewhere, the Manufacturing Technology Centre (MTC) in Coventry, UK, opened a new innovation hub for metal additive manufacturing. This facility, which further enables a new stage for the award-winning DRAMA project, acts as a physical testbed for the integration of full, digitally-linked, 3D printing process chains in the aerospace sector.

Not to be confused with the MTC, 3D Printing Industry attended the Third Munich Technology Conference (MTC3) at the Technical University of Munich (TUM) which sought to evaluate the status of additive manufacturing industrialization.

Behind the headlines of the Halle Terror attack

Furthermore, 3D Printing Industry delved deeper into the claims that a 3D printed gun was used in the terrorist attack on a synagogue in Halle, Germany. Such claims were debunked upon speaking with researchers at the International Centre for the Study of Radicalisation (ICSR) at King’s College London.

For the latest 3D Printing Industry news you can trust, subscribe to our 3D Printing Industry Newsletter, follow us on Twitter and like us on Facebook.

Looking for a fresh start in the new year? Visit 3D Printing Jobs to get a head start.

Featured image shows Rendering of Relativity Space’s Terran rocket launching from Cape Canaveral’s LC-16 launchpad. Image via Relativity Space.