During March 2019, developments in aerospace and construction continued. Moreover, the Wohlers report was published as well as responses on the U.S. Bureau of Industry and Security proposal to extend control on exports emerging technologies provided further insights on additive manufacturing.

Emerging technologies and export control

Following last year’s quest to extend its export controls across a class of deemed “emerging technologies,” the U.S. Bureau of Industry and Security (BIS) received over 200 documents outlining stakeholder views on the changes.

The main responses from the 3D printing industry, including Airbus, Boeing, Stratasys, and Carbon, express concern towards the BIS’ proposal and expressing a clearer definition of the supposed “emerging technologies.”

Wohlers Associates, Inc. published the Wohlers Report 2019 on the state of 3D printing and additive manufacturing.

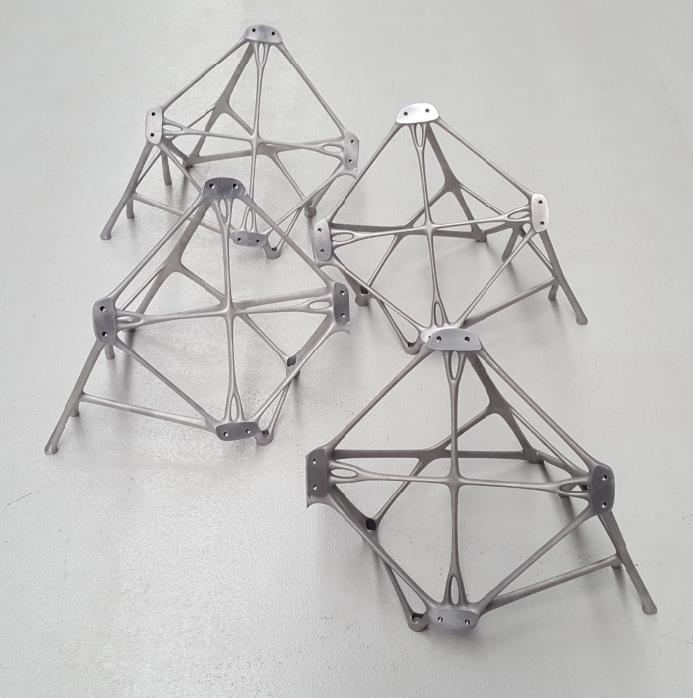

3D printed satellites, frames, and pressure vessels

In aerospace, Franco-Italian aerospace manufacturer Thales Alenia Space began using 3D printing in a series production of its satellites, otherwise known as the Spacebus NEO platform. The first run of these additively manufactured components has been integrated into a commercial satellite project for Eutelsat Communications.

The Spacebus NEO platform is a line of all-electric geostationary telecommunications satellites that are being developed with the support of the European Space Agency (ESA) and CNES, France’s National Centre for Space Studies.

Cranfield University and spinout company WAAM3D also unveiled two of the most high profile parts they have ever developed using wire arc additive manufacturing (WAAM) technology.

The first, the rear frame for a Eurofighter Typhoon aircraft, produced for British defense company BAE Systems and the second, a prototype pressure vessel developed in collaboration with a Franco-Italian aerospace manufacturer Thales Alenia Space and Glenalmond Technologies.

Lights and construction

The Lighting Research Center (LRC) of Rensselaer Polytechnic Institute, New York, formed a consortium to explore the potential of 3D printing for solid-state lighting, building, and construction industries.

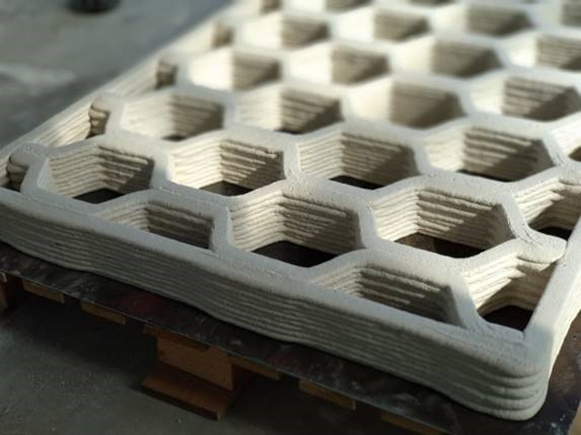

Furthermore, the 3DCONS, a Spanish construction consortium, completed a collaborative 3D printing R&D project “for the rehabilitation of claddings by direct printing and manufacture of prefabricated elements “à la carte” (without molds or formwork).”

Also within the construction sector, Al Kathiri Holding, a middle eastern building materials company, also received approval from the Saudi Arabia Ministry of Housing to develop and utilize 3D printed concrete for government-based projects.

Elsewhere, Carbon and adidas expanded its collaboration for the line of shoes utilizing Futurecraft 4D technology, with the addition of British fashion designer Stella McCartney, thus, creating the Stella McCartney x adidas AlphaEdge 4D shoe.

WACKER, the Munich-based chemical group behind the ACEO silicone rubber 3D printing brand, opened its first ACEO Open Print Lab in Ann Arbor, Michigan.

Finally, in education, Boston-based 3D printer manufacturer Markforged launched its Additive Manufacturing University program – a new scheme of workshops, learning exercises, on-site training, and resources.

For more of the latest 3D printing news subscribe to the 3D Printing Industry Newsletter, follow us on Twitter and like us on Facebook.

Also, visit 3D Printing Jobs for new opportunities in your area.

Featured image shows a prefabricated construction element 3D printed without molds or formwork. Image via Atanga, a consortium member of 3DCONS.