Avon Engineering Services Ltd is now the UK distributor/supplier for Fiberlogy, an FFF/FDM 3D printer material manufacturer headquartered in Poland.

Recently, the engineering team at 3D Printing Industry were given the opportunity by Avon Engineering to sample Fiberlogy’s material range.

Fiberlogy PET-G, Easy PLA and Fiberflex 40D were tested using 3D printable models from the MyMiniFactory community, with each model adding a different level of complexity to the task.

The engineering team performed the tests below on two low-cost desktop machines, the Anycubic i3 Mega 3D printer and a Dremel 3D20. The print profiles are recorded at the end of the article.

Fiberology Easy PLA, PET-G and Fiberflex 40D

Easy PLA is Fiberlogy’s standard filament and intended for use in any basic 3D prints, the material is specially adapted to to make objects like household items, accessories, toys and ornaments.

With a higher rigidity than ABS, and chemical resistance, PET-G is a material for functional prototyping and end-use parts.

And Fiberflex 40D is a rubber like filament with high impact resistance, suited to amateur and professional applications.

Feature test with supports

The Venus Callipyge is part of the Louvre sculpture collection in Paris. Captured and modeled by Scan the World, this miniature replica of the Venus serves a test for a material’s ability to create defining features of a design. It is also a test of the material 3D printed as supports.

3D printing at 200°C, the lower end of the material’s recommended temperature range, the Easy PLA Venus yielded positive results on the first try.

3D printing the Venus in PET-G, this time at 240°C, the team reported very good result.

The sculptures’ features, e.g. eyes, nose, hair, clothing, are accurately picked out in both models, though appear more striking in the white Easy PLA due to the color of the filament.

Support-free benchmarking test

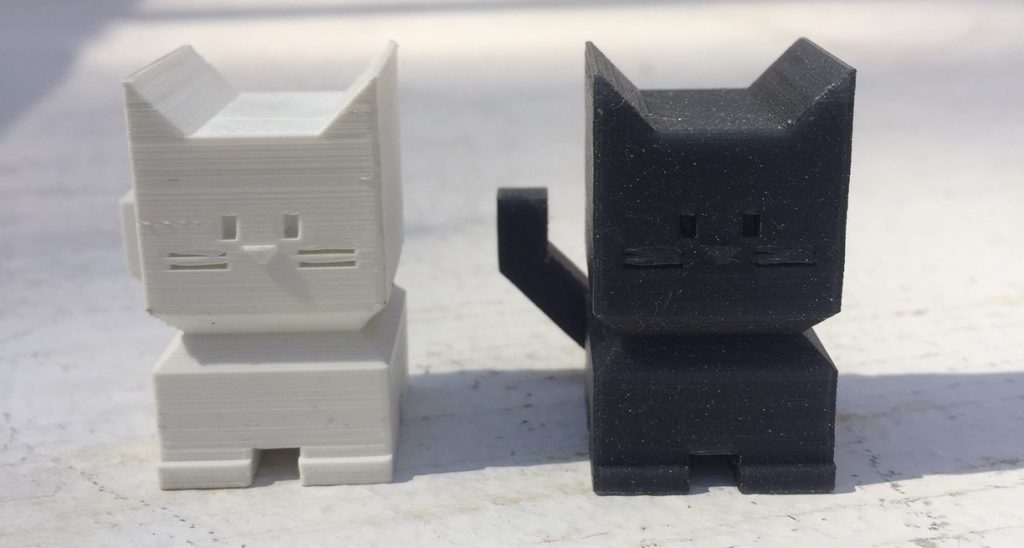

In a second test, the team used the Calibration Cat (Cali Cat) by Dezign. Like the famous 3D Benchy, the Cali Cat is a simple test used as a benchmarking print for new materials/3D printers. It is designed with features angled at 45° so it can be 3D printed entirely without supports.

3D printing the Cali Cat in Easy PLA, the temperature had to be raised to 210°C to achieve the right quality.

In Fiberflex 40D the team achieved great results 3D printing the Cali Cat at 220°C (with an ambient print bed) on a Dremel 3D20 3D printer.

A PET-G Cali Cat, on the other hand, provided a “perfect” print on the first try.

There are more visible lines on the white Easy PLA Cali Cat, but the light “sparkle” effect of the gray PET-G gives an aesthetically pleasing finish.

Functional spare part

Third, a battery cover for the back of computer mouse was tried to prove the functionality of the materials.

This part effectively 3D printed across the board, though Easy PLA and PET-G were more fit for purpose due to rigidity.

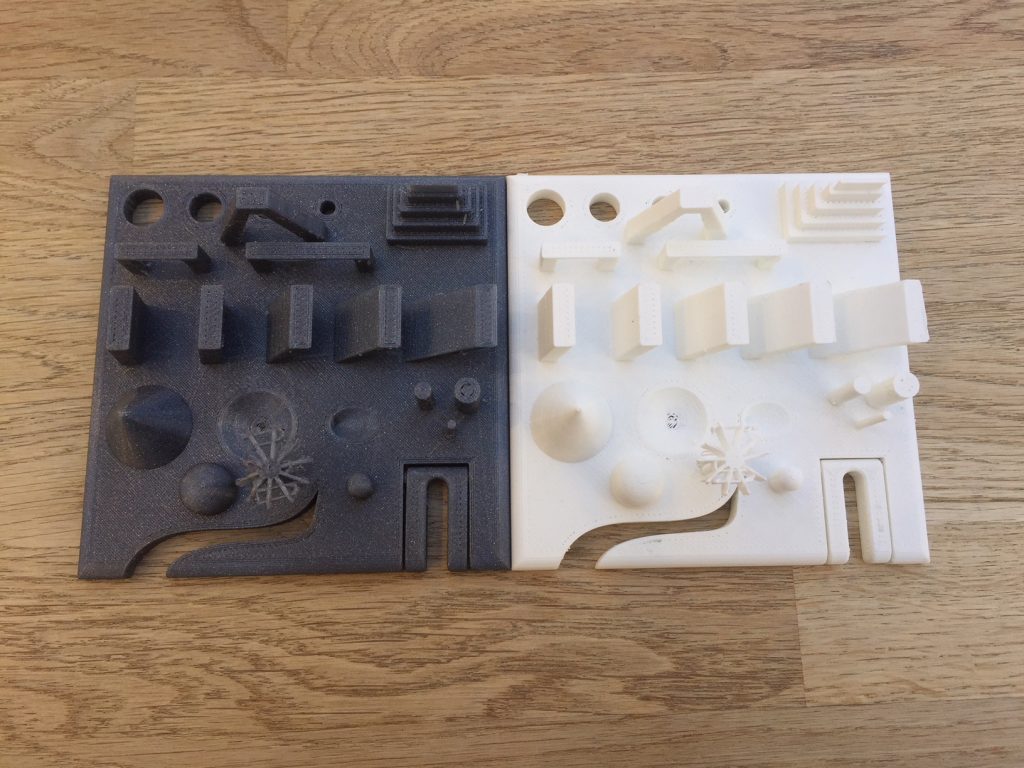

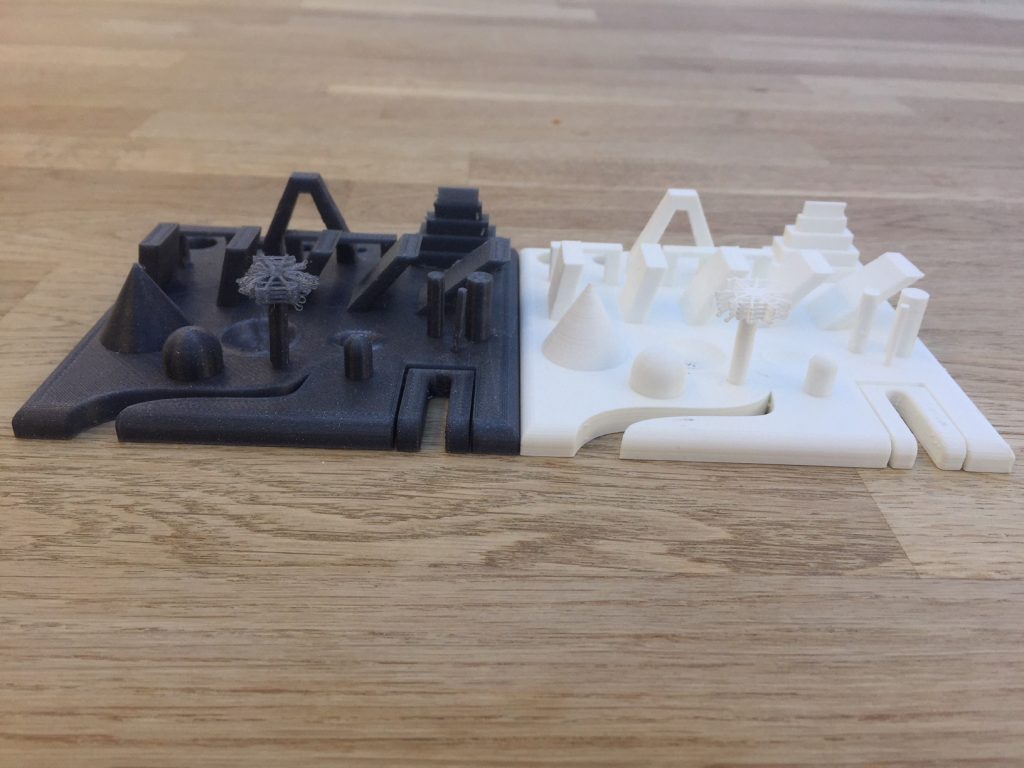

Torture test

Finally to fully test overhangs, bridges, hinges and the floating strings required to make designs like the Hairy Lion by Primoz, our engineers selected Ian Robinson’s Torture Test as a sample model.

In Easy PLA, the Torture Test achieved “good” results – no stringing between bridges or overhangs, and an easy moving hinge.

The Torture Test in PET-G was even better quality than Easy PLA, 3D printing with clean lines and creating a good “hairy” effect on the tree of the tile (pictured below, left of center on grey tile).

Anycubic i3 Mega settings

For reference, all objects apart from the Cali Cat made from Fiberflex 40D were 3D printed on an Anycubic i3 Mega 3D printer using the following settings. In the Cali Cat Fiberflex 40D test we switched to a 3D printer without a bowden setup.

Slicer: Simplify3D, using a manually created profile

Primary layer height: 0,1200 mm

Infill: 20%

Support: 20%

PLA print temperature: 210°C & 200°C

PLA bed temperature: 60°C

PET-G print temperature: 240°C

PET-G bed temperature: 30°C

Print speed: 2200 mm/min to achieve high quality prints.

Dremel 3D20 settings

Setting for the Dremel 3D20 used to 3D print the Cali Cat. (Retraction, support, brim, no draft)

Primary layer height : 0,200 mm

Infill: 20%

Support: 30%

Fiberflex 40D print temperature: 220°C

Fiberflex 40D bed temperature: ambient

Print speed : 2400mm/min

Fancy trying out Fiberlogy filaments yourself? The full range of materials, PET-G, Easy PLA, Fiberflex 40D and more are available to buy online from Avon Engineering Services.

Featured image shows test 3D prints in Fiberlogy PET-G, Easy PLA and Fiberflex 40D.