3D Printing Industry is currently seeking feedback on material usage across the sector. Have your say in the Spotlight on Resin 3D Printing Survey now.

In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions in the additive manufacturing sector.

Today’s edition features a host of new reseller agreements, marine and veterinary applications and 3D printing defense certifications, as well as maker innovations ranging from an open-source conveyor mod to trendy Wordle wearables.

Read on for the most recent updates from Anisoprint, JawsTec, AddiTec, Filamentive, 3D Metalforge, Optomec, Additive-X and more.

Stratasys & Optomec gain new orders

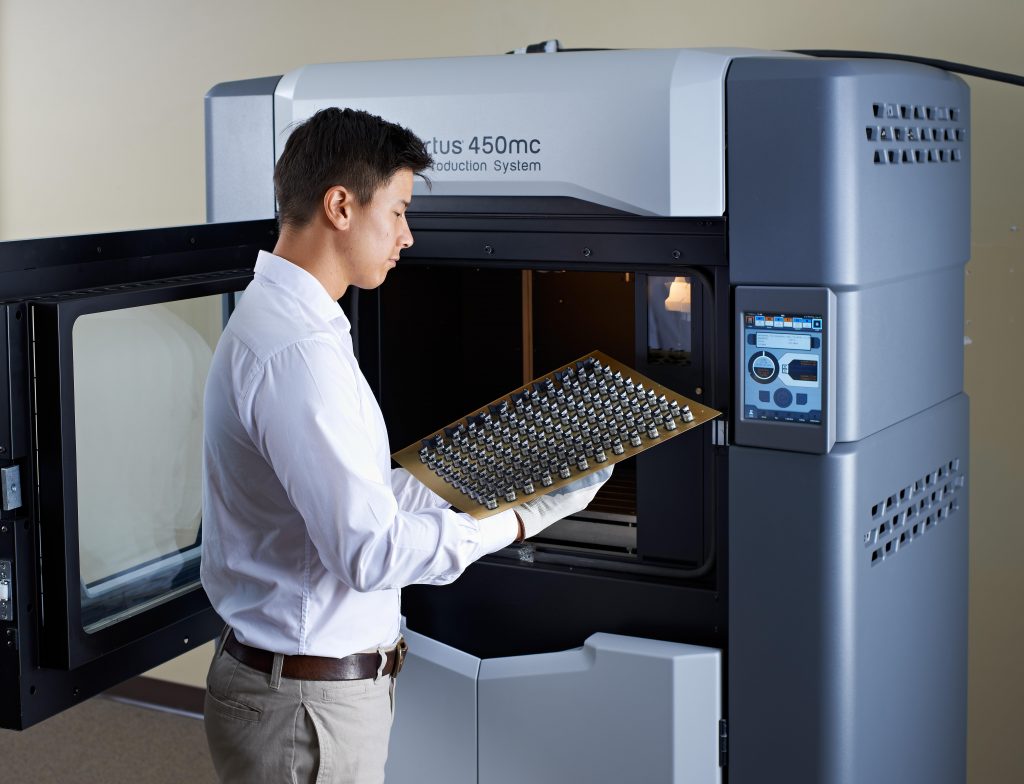

Beginning this week’s update with orders and installations, UK manufacturing service provider Brookhouse Aerospace has announced the acquisition of Stratasys’ Fortus 450mc system via reseller SYS-UK. By installing the Ultem 9085-compatible machine, the firm believes it will be able to better support its aerospace and defence clientele, particularly in the acceleration of their low-volume R&D.

“Our new Stratasys 3D printing machine provides versatility when working with customers on new projects,” Brookhouse Aerospace CEO Christopher Morris told Aerospace Manufacturing. “This capability is a real step forward in supporting our customers’ needs, and again demonstrates Brookhouse Aerospace’s commitment to supporting their current and future requirements.”

“We now have the ability to take a customer’s idea and place a real part in their hands in days rather than weeks.”

Over in the US, industrial 3D printer manufacturer Optomec also says that it has received a $1.25 million order for a “production metal additive manufacturing machine.” Although the firm hasn’t disclosed either the system purchased or the identity of its buyer, it has revealed them to be a Fortune 500 energy equipment supplier, intending to use the 3D printer to “maintain industrial gas turbine components.”

“We are pleased to see that, despite COVID and supply chain issues, our customers are making capital investments to increase their efficiencies.” said Mike Dean, VP of Marketing at Optomec. “We expect continued growth in adoption of our cost-saving solutions in the gas turbine industry, especially given that penetration rates are low while ROI’s are high and improving as we introduce more turnkey processes and integrated automation.”

Business moves made by Meltio, Anisoprint, Anduril and more

Moving onto business news, continuous fiber 3D printer manufacturer Anisoprint has announced that Sedaxis Advanced Materials has agreed to resell its machines in the Indian market. As part of an exclusive distribution partnership between the firms, Sedaxis is now set to offer Anisoprint’s technologies in the country, where it’s anticipated they will find a strong level of demand within academic research.

“Until recently, the Indian ecosystem has had to endure a lack of options in continuous composite 3D printing systems,” explains Vishwanath Godavarty, Business Head for 3D printing at Sedaxis. “The introduction of Anisoprint’s fully open systems in India in 2019 has had an overwhelming response from some of India’s leading research institutions and universities.”

Likewise, 3D printer OEM Meltio has made AddiTec an Official Sales Partner as part of its efforts to accelerate its expansion into the North American metal additive manufacturing market. In its new role as a distributor, AddiTec is set to focus on building a clientbase for Meltio’s technologies across the US and Canada, particularly among tooling machine firms, robotic integrators and academics.

On the military front, meanwhile, defense contractor Anduril Industries has announced the acquisition of 3D printed autonomous underwater vehicle (AUV) manufacturer Dive Technologies. Having been bought, the firm, which is known to additive manufacture elements of its customizable ‘DIVE-LD’ deep-sea surveillance system, believes it could now have the resources to expand its operations.

“We built Dive to make undersea exploration safer, smarter and cheaper, and to offer customers the highest level of customization,” said Dive Technologies CEO Bill Lebo. “With Anduril, we will rapidly scale our team, technology, and production to ensure our military partners have the best, most strategic advantage, and our commercial customers have the most reliable tech in the greatest depths of the world’s oceans.”

Lastly in this week’s business update, 3D printing bureau JawsTec has also attempted to expand the reach of its offering, by beginning to accept bitcoin as a method of payment for its services. According to the company, the digital currency enables much faster, cheaper and more secure transactions to take place, thus it’s “excited about the opportunities and possibilities,” opened via its adoption.

JawsTec adds that its motto is to make the ‘highest quality 3D printed parts as affordable and accessible to their customers as they can,’ and it anticipates that adding bitcoin as a payment method will help it “progress towards this goal.”

Filamentive unveils student discount scheme

Elsewhere, in the world of 3D printing materials, filament developer Filamentive has announced that it has become the first UK firm of its kind to begin offering a student discount. Although the company says that its primary source of business remains B2B transactions, it also claims to actively support many universities, both by supplying or engaging with groups of their pupils.

Not wanting to price these students out of engagement in 3D printing activities, the firm has therefore introduced a 20% discount. Available to any UK student, lecturer or academic staff member with an ‘.ac.uk’ TLD email address, the promotion is said to be applied automatically to the baskets of eligible customers upon checkout.

“Students are increasingly telling us they want to switch to a more sustainable filament for their 3D printing endeavors, but they cannot afford to do so,” explains Ravi Toor, Managing Director of Filamentive. “With our student discount scheme, we are overcoming that barrier to purchase.”

Novel marine, veterinary and industrial projects unveiled

Kicking off this week’s application update with 3D Metalforge, the 3D printing service provider has penned a new deal with the subsidiaries of oil and gas firm Par Pacific Holdings, in which it has agreed to supply various additive manufactured marine parts to Par Pacific’s US refineries, including impellers and sleeves amongst others.

Building on the successful field trials the companies carried out last year, their renewed partnership will see them work to identify opportunities in Par Pacific’s operations, where it could be advantageous to print spare parts instead. Although the deal could be worth up to A$400,000 per year, it’s said that the order has no minimum value, thus its outright cost will depend upon the Par Pacific’s needs.

“We are thrilled to have concluded a successful field trial and to be moving toward increased production with Par Pacific,” said 3D Metalforge CEO Matthew Waterhouse. “Once this phase of the work is complete, we will discuss the possibility of placing a production center at their refineries, to further reduce the delivery time of parts and improve supply chain sustainability.”

“We enjoy a good working relationship with Par Pacific, and look forward to continuing to support their spare part needs.”

In a similar, industrially-focused application, custom robotics specialist Labman Automation has also revealed how turning to Markforged 3D printing has allowed it to reduce its production costs by as much as 75%. At present, the firm produces lab automation gear that’s personalized to the needs of each client, thus to rapidly iterate upon these parts in low volumes, it previously installed an FDM system.

However, Labman Automation is said to have found the machine’s unreliability and cost-per-part to be too much to bear, thus it acquired a Markforged 3D printer via Additive-X as a replacement. According to the company, doing so has enabled it to begin prototyping and producing end-use parts on the same unit, while also allowing it to reduce the amount it outsources, and its associated costs.

The project’s leader Tom Gale has spoken highly of the finish Labman Automation has been able to achieve through its adoption of Markforged machines as well, observing that: “if you’ve spent a million pounds on a robot, and it looks like it was 3D printed with a £300 printer, you’re going to be a bit upset. So it’s nice for us that it has that extra aesthetic side.”

Lastly, 3D printer manufacturer Zortrax has revealed how its technology is being applied by veterinary student Maciej Szczepański to aid the walking wounded in the animal world. Working from a lab at the Wrocław University of Environmental and Life Sciences, Zortrax says that Szczepański has managed to use an Inventure unit to create prosthetics for ‘Sonia’ and ‘Leto,’ two dogs maimed in traffic accidents.

Made almost entirely using 3D printing, these protheses have now been tested by both canines successfully, with the labrador Leto said to be capable of moving “like a healthy dog” within 15 minutes of treatment. Moving forwards, having demonstrated the efficacy of his approach, Szczepański aims to set up his own start-up, which will work to help animals suffering from various orthopedic issues.

Protolabs gains ‘JOSCAR’ recognition

Digital manufacturing service provider Protolabs has been awarded Joint Supply Chain Accreditation Register or ‘JOSCAR’ certification. Manufacturers are only able to gain the invite-only accreditation by demonstrating the commitment, reliability, technical ability and capacity, to help customers meet regulatory requirements when it comes to managing third party risk in the supply chain.

Even though it has already supported the aerospace, security, space and defense industries for several years, Protolabs says that becoming recognized as JOSCAR-compliant means that it could now be a “credible supplier” of “major businesses within associated industries,” with the likes of BAE Systems, NATS, Rolls Royce, Airbus and the Ministry of Defence all known to value the industry standard highly.

“We take great pride in achieving excellence in this way,” said Bjoern Klaas, VP and MD of Protolabs Europe. “We are already a well-established service provider to the aerospace supply chain, but this accreditation, alongside our ISO 9001 quality award, will further cement our reputation in the wider security and defense industries.”

Maker 3D prints conveyor mod

The maker community is so-often a hotbed for 3D printing innovation, and this week proved to be no exception, with Youtuber Call Me Swal using his ingenuity to develop a mod for turning an FFF machine into an ‘infinite conveyor belt’ system.

To achieve this feat, the Youtuber turned the print bed of an Artillery Hornet 3D printer into a conveyor using a set of nearly entirely printed parts. Driven by the machine’s original stepper motor, the resulting setup is said to not only be capable of depositing material at a 45° angle, but producing ‘infinitely-long prints,’ as it can move in one direction without hitting the height limits of conventional systems.

In order to allow this modified printer to operate using its new hardware, the Youtuber also tweaked its firmware, to remove its end-stop value for the conveyor axis and enter a larger one for that of its max belt position. He also found that using a custom slicer was needed to make the G-code for print jobs, and provided links to all of the above on his channel, allowing makers everywhere to try the mod as well.

“By adding a conveyor belt, my 3D printer can now print infinitely-long print-outs,” Call Me Swal said in his video. “This mod has completely changed what I can make on my 3D printer and it’s surprisingly easy to do. You don’t need any expensive equipment, you don’t need any fancy machines, all you need is eight minutes (the length of the video).”

Although it should be noted that they may need some tweaking to work on non-Hornet systems, the parts needed to build the conveyor system can be found here.

The Wordle trend creeps into AM

Finishing this week’s round-up with a trend that goes well beyond the world of 3D printing, another maker known as kriswillcode, has developed a way of turning scores generated in the popular Worldle online game into an additive manufactured model.

Formed of front and back panels, as well as a set of 15 multicolored cubes, the device can be assembled and attached to a lanyard, in a way that allows wearers to brag about their scores to their heart’s content. As an alternative, software developer Vicky Somma has also put together a piece of code that allows scores to be outputted as an STL file, with users able to pause prints to change colors.

Although Somma hasn’t made her code public just yet, kriswillcode has theirs available to download here.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper-dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, de-briefs and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Sliced logo on Anduril Industries’ partially-3D printed DIVE-LD AUV. Photo via Anduril Technologies.