In this week’s first edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions across our industry.

Additionally, you’ll find out what the MACH 2020 show has to offer in 3D printing, investment in additive manufacturing in Scotland, and a 24k gold-plated titanium bike. Read on for the latest updates from the likes of VELO3D, Renishaw, Mogassam, EOS, Victrex, and Titomic.

Acquisitions and partnerships in the 3D printing industry

U.S.-based 3D printer reseller DELRAY Systems has signed an agreement with 3D Herndon, a Master USA Distributor for Sinterit, the Polish manufacturer of SLS 3D printers. As part of the agreement, DELRAY will now be able to sell and service the full line of Sinterit SLS 3D printers and accessories.

3D Herndon became a certified distributor for Sinterit in October 2019. As well as providing Sinterit’s Lisa series of 3D printers, the company also offers training, service, and support to customers in the U.S..

“The level of strength, and detail the Sinterit system is able to produce is astonishing,” comments Joe Rocca, President of DELRAY Systems. “We are very fortunate to team up with 3D Herndon and offer this best in class technology to the industry and educators.”

Swedish 3D printing service provider Prototal AB has acquired Danish 3D printing prototyping firm Damvig A/S. With the acquisition, Prototal AB aims to strengthen its market position within Northern Europe, particularly within the Scandanavian region, and encourage the adoption of 3D printing within the region as well. Recently, Prototal joined the HP Digital Manufacturing Network to help provide HP’s polymer and metal 3D printing technology.

3D printers from VELO3D and Renishaw

Knust-Godwin, a Texas-based precision-tool and component manufacturer, has purchased a Sapphire metal 3D printer from VELO3D, a Californian metal 3D printer manufacturer. The new system will join Knust-Godwin’s existing fleet of seven metal 3D printers. Delivery of the Sapphire 3D printer is due in the first quarter of 2020. The company has already secured orders to 3D print end-use parts using the system for the oil service industry.

Michael Corliss, VP of Technology for Knust–Godwin states, “We see so many parts that have been manufactured with traditional methods that could take advantage of the benefits from AM. Our new Sapphire system provides the accuracy and low-print-angle capabilities that enable recreation of those parts via AM without having to go through a complicated redesign process.”

“We can finally print parts as-is, offering valuable cost-savings to our customers and improved turnaround time for delivery.”

VELO3D has announced a number of sales of its Sapphire 3D printer recently, including a seventh system to its largest production customer, which had already ordered 12 systems from VELO3D in the past year.

H.C. Starck Solutions, a global manufacturer of metal powders, has expanded its 3D printing capabilities with the addition of a laser powder-bed fusion printing system from British engineering firm and metal 3D printer manufacturer Renishaw. The company plans to use the new 3D printer to optimize the processing of its refractory alloys, and to produce complex metal parts in support of its customers in the aerospace, defense, medical, and industrial markets. H.C. Starck Solutions plans to install the Renishaw system at its manufacturing facility in Coldwater, Michigan.

“Renishaw’s powder-bed fusion system offers the best combination of high precision and geometric flexibility of any current AM technique,” states Andreas Mader, Chief Executive Officer of H.C. Starck Solutions. “Combining our knowledge of AM technologies with our expertise in refractory metals will provide our customers with superior solutions to their business needs. The addition of the powder-bed fusion technology from Renishaw is only one of many steps H.C. Starck Solutions is taking to expand its AM portfolio in support of this growing sector.”

End-to-end solution for dental 3D printing

Mogassam, a Delaware-based 3D printer manufacturer, has announced that its DentCase dental 3D printer and DentPrint automated dental CAM software has been validated for use with scanning technology from Medit, a provider of 3D measurement and CAD/CAM solutions for dental clinics. Specifically, users are now able to pair Mogassam’s product with the Medit i500 intraoral scanner. Therefore, as well as 3D printing dental aligners, Mogassam is providing its customers the tools to scan and gather the data for producing said molds.

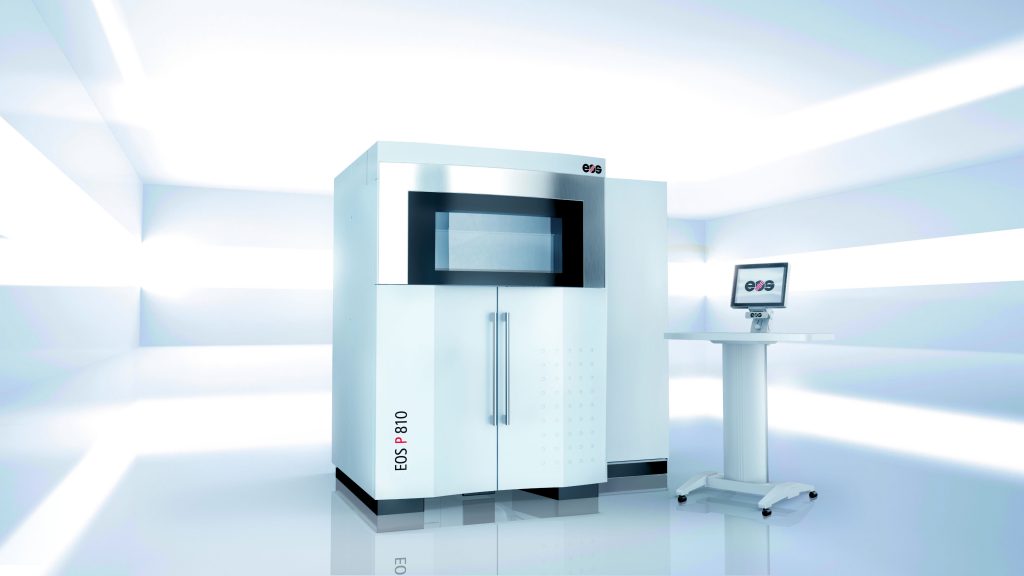

The University of Exeter and UK-headquartered performance plastics developer Victrex have successfully commissioned the EOS P 810 3D printer for use with Victrex’s high-temperature polymers. Specifically, the partners have optimized the Victrex PAEK polymers and composites for use on EOS’ SLS 3D printing platform. The new EOS P 810 is capable of printing with materials that have melting temperatures around 300°C (572°F), suitable for the low-melting-point of Victrex’s PAEK polymers. The machine was commissioned by the Centre for Additive Layer Manufacturing (CALM) at Exeter.

“We can now further our research by utilizing the next generation of high-temperature systems, the EOS P 810,” explains Professor Oana Ghita, the lead of CALM at the University of Exeter. “The new equipment allows us to link the fundamental research with the commercial manufacturing process, to optimize the materials and their application, while accounting for the new thermal, optical, and mechanical upgrades and providing us with accurate insights into the detailed dynamics of laser sintering.”

Raising money for Australia

At the 2020 MACH trade fair, a UK show dedicated to manufacturing, German machining solutions specialist MAPAL will be introducing its 3D printed bell cutting tools. Using metal 3D printing, MAPAL has been able to optimize the weight of its bell tools without sacrificing the strength and integrity of the components. Leveraging an SLM 3D printer, MAPAL was able to modify the internal design of the bell tool and reduce its weight by 30 percent. Additionally, the company optimized the cooling channels of the bell tool to increase the efficiency of its cutting fluid delivery. Taking place from 20 to 24 April, MAPAL will be exhibiting at MACH 2020 in Hall 18, Stand 330, where visitors can see the 3D printed bell cutting tools.

Scottish 3D printing service provider Angus 3D Solutions has received a £39,000 Regional Selective Assistance (RSA) grant from Scottish Enterprise, a non-departmental public body of the Scottish Government encouraging economic development and investment in business. Utilizing the funding, Angus 3D plans to act out a three-year growth plan focused on expanding its manufacturing capabilities. The company’s 3D printing arsenal includes the Metal X system from Markforged, having received a £175,000 grant from Zero Waste Scotland.

Titomic, an Australian metal 3D printer manufacturer, alongside its bicycle brand, Vaaru Cycles UK, have announced they are raising money for the Victorian bushfire appeal. The companies are auctioning a luxury, 24k gold-plated titanium bike, currently on show at the Dubai International Bicycle Exhibition with a reserve price of US $25,000. Taking over 100 hours to be built, it features components from biking companies Sram, Enve, Lightweight, Brooks, and Vittoria. The auction of the Vaaru Octane 6-4 Disc 24-gold karat and pearl white road cycle will conclude at the end of the three-day event (11 January). The proceeds of the highest bid to be donated to the Australian Red Cross.

Finally, Oklahoma additive manufacturing service provider Rapid Application Group (RAG) has held the grand opening ceremony of its new state-of-the-art 15,000 sq. ft. additive manufacturing facility. Attending the ribbon-cutting event were founders Terry Hill and Jason Dickman, the entire team from Rapid Application Group, the team from the Chamber of Business of Broken Arrow, and Jonesy the Dog (see photo below).

The new building will help to expand the company’s production capacity for serving its customers, carried out through a wide array of 3D printing and traditional manufacturing technologies. Primarily, RAG is focused on delivering 3D printed parts to the aerospace and defense sector. Recently, the company received AS9100 Rev. D quality certification, a standard benefiting aviation, space and defense industries as it assures production meets quality requirements of the Department of Defense (DOD), NASA and the FAA.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows SLICED logo on a photo of Vaaru Octane 6-4 Disc 24-gold karat and pearl white road cycle. Original Photo via Vaaru Cycles.