In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions in the additive manufacturing sector.

Today’s edition features the latest 3D printer upgrades, advances in surgical implants, performance enhancing NASCAR parts, additive fighter jet parts and a fully-3D printed golf club.

Read on for the most recent updates from nScrypt, Evolve Additive, DP Technology, DiManEx, Liqcreate and more.

Machine updates from ExOne, nScrypt, and Evolve Additive

Starting this week with the latest system upgrades, binder jetting 3D printer manufacturer ExOne has launched a new desanding station. Designed for use with its S-Max and S-Max Pro systems, the firm’s latest machine features two vacuum-powered wings that help users to remove excess sand.

ExOne claims that its accessory is capable of improving throughput for its clients by up to 50 percent while reducing the costs associated with removing sand molds and cores from the job box. The Swiss-based Eisengiesserei Mezger AG iron foundry recently adopted the desanding device, and claimed that it helped to automate its overall production process.

“Our new desanding station is another step forward as we work to deliver smart, complete and sustainable 3D printing solutions for our customers,” said John Hartner, ExOne’s CEO. “We have an exciting new portfolio of automation solutions in development and on the way for our industrial sand and metal 3D printers.”

Microdispensing specialist nScrypt has released a new IDS aerosol jet printhead as an optional accessory for its Factory in a Tool (FiT) 3D printer. The nano jet tool head is capable of printing features between 10 µm and 200 µm wide, making it especially useful for fabricating electronics such as conductors or resistors.

Integrating aerosol jetting into their FiT systems also provides adopters with access to a dispensing range that can be used further from the printing surface. This trait allows for the creation of thick films where the width and depth of lines are important. Overall, the company believes that its accessory provides enhanced flexibility, particularly in R&D applications.

“Next generation circuits will feature fine lines, both thick and thin, and substrates that are smooth and rough,” said Dr. Ken Church, CEO of nScrypt. “Our FiT now combines microdispensing for wide material choice and higher viscosity with aerosol jetting for fine features that benefit from thin, highly conductive lines.”

Evolve Additive, the former subsidiary of Stratasys, has announced that it has sold its first machine to feature its proprietary STEP 3D printing technology. Although the firm wouldn’t name the buyer for confidentiality reasons, it did reveal that the client acquired a factory-optimized SVP system, which will be delivered in Q1 2021.

“Not only did our first customer purchase the SVP platform but the sale also included software and materials,” said Steve Chillscyzn, CEO and Founder of Evolve. “We are very excited to work with this organization and start to see how the use of our technology will streamline their efficiencies, increase profits, and provide them with visibility.”

GE Additive and Stratasys make medical advances

Medical device manufacturer Tsunami Medical has announced that it has installed two more GE Additive Concept Laser Mlab systems to accelerate the production of its spinal implant products. By working with orthopedic medical staff, the company has managed to deploy the systems to develop customizable PEEK one-piece implants.

GE’s DMLM technology has also enabled the medical firm to optimize parts such as its latest product: the Giglio Interspinal Fusion System. The device, which features a small interspinal spacer, was made possible thanks to Tsunami’s new 3D printer, which allowed it to create the product’s precise geometries in intricate detail.

“DMLM helps us achieve the accuracy, complexity and functional integration we are striving for,” said Stefano Caselli, Tsunami Medical’s Founder and GM. “It also delivers a great surface quality that reduces or sometimes eliminates the need for typical post-processing, which in turn drives productivity gains.”

3D printer manufacturer Stratasys has revealed that it has now installed its J750 Digital Anatomy systems in the US, China, Australia, and various European markets. Seattle Children’s Hospital purchased one of the systems earlier this year to create soft models in-house that duplicate body parts such as airways, livers, and hearts.

Similarly, Nicklaus Children’s Hospital upgraded from its existing Eden 260 to the J750 as part of its Cardiovascular Surgery Program. According to Dr. Redmond Burke, Chief of Cardiovascular Surgery at the hospital, personalized medicine has now become a critical part of the surgical planning process.

“It’s very valuable to be able to actually cut open a model to get a very clear vision of what we’ll see in the operating room,” explained Burke. “We believe this is a significant advance that will allow us to reduce the trauma of patients undergoing complex heart surgery.”

Liqcreate launches its first-ever castable resin

Netherlands-based 3D printing material manufacturer Liqcreate has released its first-ever castable resin called ‘Wax Castable.’ The blue photopolymer has been specifically designed for use within laser-based systems including those featuring liquid crystal mask technology (MSLA) or Digital Light Processing (DLP) engines.

Liqcreate says that its material provides good processability and accuracy while being able to capture “intricate” features and “crisp” details. As the polymer is based on wax, it’s also conducive to producing smooth surfaces, which potentially makes the plastic suited to printing jewelry as well as dental or industrial parts.

The resin is now available for purchase, and the company’s engineers are seeking to work with industrial partners to increase the number of 3D printers it’s compatible with.

Fraunhofer and UK university invests in AM’s future

The UK-based Manchester Metropolitan University has teamed up with prototyping firm Fabricon Design to run a specialized Fast Track Additive Manufacturing program. Held as part of the wider ‘Made Smarter’ project, the 12-day course will provide local businesses with an understanding of 3D printing technologies including hardware, software, and materials.

Running from now until February 2021, the modular program has been designed to fit around trainees’ work schedules and features a blend of online and in-person classes. Many of the companies taking part have either installed a 3D printer or are weighing up their options, making the course an informal way for them to learn of the technology’s benefits.

“This pioneering program is designed to advise businesses on how they design products for AM and operate the machines, and what benefits they can expect,” said Ruth Hailwood, Made Smarter’s Workforce Development Advisor. “Businesses will provide real world examples as training material so that the course will address their specific skills gaps.”

Six of Fraunhofer’s institutes (known as the Fraunhofer-Gesellschaft), have announced the conclusion and results of their futureAM Project. Over the last three years, the researchers have made significant advances in 3D printing with regards to systems engineering, materials and process control as well as reducing costs and end-to-end digitalization.

Fraunhofer IAPT, for instance, has developed a suite of user-friendly web-based simulation tools for metal 3D printing, while the ILT institute has produced an “XXL” 1000 mm x 800 mm x 400 mm PBF system. Elsewhere, Fraunhofer IWU has even developed a code based on 3D scans, that allows users to trace a part through the entire post-processing workflow.

For Christian Tenbrock, futureAM’s Project Manager, the research project’s collaborative approach has resulted in a “new generation” of 3D printing technologies. “We are now on the threshold of industrial implementation,” said Tenbrock. “The expertise we have gained together is now to be transferred to industrial application.”

Business news from Dimension Inx, BCN3D, and more

Biofabrication company Dimension Inx has announced the closure of a $3.175M Series Seed financing round. The investment, provided by KdT Ventures, Better Ventures, and Revolution’s Rise of the Rest Seed Fund, will be used to fund the development and FDA approval of the company’s first therapeutic facial implants.

Dimension’s patented facial reconstruction technology is being developed to help patients following trauma, as well as those with dental malformations due to congenital defects or aging. The firm expects to complete preclinical studies surrounding its manufacturing platform for FDA 510(k) submission by next summer.

“We are incredibly fortunate to partner with investors who support our big vision and appreciate our pragmatic approach to the market,” said Dr. Caralynn Nowinski Collens, CEO of Dimension Inx. “We’re looking forward to advancing the science and expanding our strategic partnerships to address a much broader set of surgical applications.”

CAM 3D printing software developer DP Technology, meanwhile, has been acquired by the Hexagon AB technology consortium. The deal will see DP Technology’s ESPRIT CAM system included in Hexagon’s Manufacturing Intelligence division, effectively providing a global platform that could boost its presence in the marketplace.

“As we are integrated into Hexagon, we will see a magnification of the qualities that make ESPRIT an industry leader,” said Chuck Mathews, Executive VP of DP Technology. “Leveraging the strengths of a multinational company, we will achieve greater velocity in the expansion of our products and services on the global CAM marketplace.”

In a funding round led by Investo Capital, and supported by Vaekstfonden’s investor arm VF Venture, the Danish R&D company Create it REAL has raised €3.1 million. The firm currently provides control systems and electronics, as well as 3D printing and slicing technologies to clients, and the new funds will allow it to reach a broader European market.

”We already knew that 3D printing has great potential, but Create it REAL is now proving that this technology can be applied to a wide range of vertical markets, digitalizing the production process,” said Jesper Jespersen, a Partner at Investo Capital. “Within the healthcare sector, with this additional funding, the company can accelerate market penetration.”

Spanish 3D printer manufacturer BCN3D has signed an agreement with service provider 3DGBIRE that will see it become the exclusive distributor of its machines in Britain and Ireland. In its new role as a “Premium Supplier,” 3DGBIRE is set to assist BCN3D’s clients in integrating additive manufacturing into their business as efficiently as possible.

As part of the deal, the firm will also provide tailor-made support and training programs for first-time adopters of 3D printing technologies, as part of its “360 degree” service. In addition, following BCN3D’s recent machine launches, 3DGBIRE will now supply the latest “cutting edge” Epsilon and Sigma systems to customers around the UK.

“We are delighted to partner with BCN3D, who shares our core values of reliable hardware, open materials, and industry-ready software,” said Paul Croft, CEO of 3DGBIRE. “This ideal partnership allows us to bring these exciting ground-breaking technologies to market with the training and service levels required by industries who are looking to maximise output from day one”.

The U.S. Air Force picks Essentium for MRO project

3D printer producer Essentium has been awarded a U.S. Air Force (USAF) contract to develop additive solutions for creating aircraft parts, as well as Maintenance Repair and Overhaul (MRO) applications. The multi-year agreement is part of a broader $550 million Strategic Financing initiative, which seeks to fund technologies that ensure the dominance of the USAF.

Within the collaborative project, Essentium will deploy its HSE 3D printing technology to accelerate aircraft repairs, and quickly get aircraft back in the air. Given the current challenges to the global supply chain, and that parts for some of the aging aircraft are now scarce, the firm also aims to reduce the overall costs and lead times of sourcing spares.

“The sky’s the limit for the potential benefits of additive manufacturing for the U.S. Air Force,” said Elisa Teipel, CDO and Co-founder of Essentium. “We are beyond thrilled to be awarded this contract and work with our government customers, to help drive significant advancement in military parts manufacturing, and advance the U.S. Air Force’s military leadership.”

Software updates from DiManEx, VoxelPrint, and BCN3D

3D printing supply chain software provider DiManEx has worked with Finland’s VTT Technical Research Centre and Aalto University to develop a new system of producing “smart” spare parts. In the joint project, the researchers studied identification methods as well as the performance, workflow, and quality assurance implications of creating a digital inventory.

Using DiManEx’s Supply Chain Inspector engine, the team was able to examine a data set of 104 original parts from 3 different companies, including vital metrics such as material, dimensions, and weight. Results showed that 33 percent of the parts studied would benefit from being 3D printed, reflecting the potential of the technology in this area.

“One of the bottlenecks for the digitalization of spare parts is finding 3D printable parts from large warehouses that can carry hundreds of thousands of items,” said Sini Metsä-Kortelainen, a Senior Scientist at VTT. “Tools like the ones DiManEx has developed enable a wider implementation of digital spare parts, and this leads to better availability.”

Concre3DLab, a research institute at Ghent University, has released a new Grasshopper plug-in for the voxel-based simulation of concrete 3D printing called VoxelPrint. The software upgrade allows users to voxelize any 3D shape into a set of identical finite elements, that can be turned into input files, and used for simulation purposes on the ABAQUS program.

Designed to be as user-friendly as possible, the software features a familiar parametric toolbox so that non-experts such as architects and designers can quickly get to grips with it. For its more experienced users, the program has still retained advanced settings though, allowing clients to optimize their 3D models where possible.

NASCAR team adopts MakerBot 3D printers

NASCAR’s Leavine Family Racing team has announced that it has adopted MakerBot’s METHOD X 3D printers to rapidly-produce prototype and end-use parts for use on its race cars. Leavine reportedly chose to use Makerbot’s machine due to its wide portfolio of compatible materials, as well as its ability to print at extremely high temperatures.

The race team needed to use materials with a high level of strength and heat-resistance to produce performance-intensive parts, and its two track-side machines enable it to do so on-demand. Using its METHOD printers, Leavine has so far produced camera pods and an air intake duct, and mounted them to the tail of the car and inside its cockpit respectively.

“We selected the MakerBot METHOD X for its advanced capabilities, which enabled us to produce better, lighter parts very quickly,” said Michael Leavine, VP of Leavine Family Racing. “METHOD is one of the most sophisticated units on the market, from the ease of connectivity, to the advanced materials we were able to use.”

New additive applications from Nanofabrica and HP

Nanofabrica, the Israeli developer of precision 3D printing technologies, has deployed its Tera 250 system to produce a series of enhanced miniaturized industrial components. Using its proprietary 3D printer, the company created an industrial impeller measuring just 5.66 mm x 5.66 mm x 2.87 mm, without the need to use complex and difficult to amend micro tooling.

In the same print run, Nanofabrica produced a fiber optic adapter which featured internal cavities for feeding 250-micron fibers through, in a more cost-effective way than manual tooling would allow. In order to accommodate the fibers, the part also needed exact dimensions of 9.0 mm x 6.0 mm x 6.0 mm, and the firm’s technology made this possible.

“We are delighted to be able to release details of some of the successes we have had using our 3D printing technology,” said Avi Cohen, EVP of Global Sales at Nanofabrica. “The Tera 250 is now proven to be a game-changer when it comes to opening up the advantages of 3D printing to the micro-manufacturing world for the very first time.”

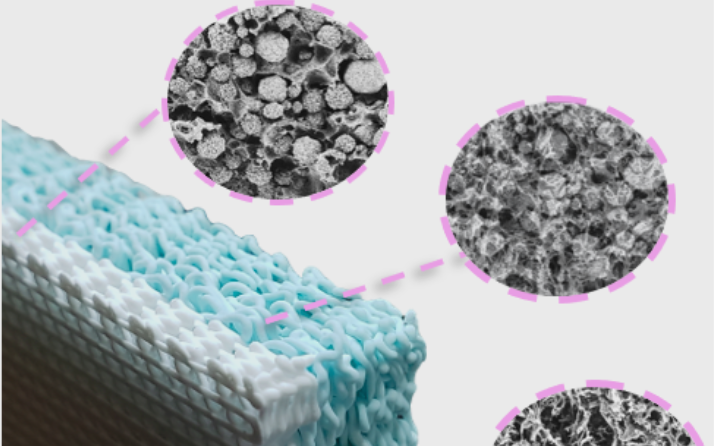

Elsewhere, golf club manufacturer Cobra Golf has partnered with HP and Parmatech to develop its 3D printed KING Supersport-35 putter. The club features a fully-printed metal body with an intricate lattice structure, that optimizes its weight distribution, and provides users with the highest level of Moment of Inertia (MOI) that’s possible with a blade shape.

HP’s MJF 3D printers were chosen to produce the iron due to their rapid processing times and design adaptability, which allowed Cobra to prototype 35 designs in just eight months. In addition to their additive putter, the companies have also agreed on a strategic, multi-year product roadmap that will see two further golf-related products launched in 2021.

“The power of personalization enabled by 3D printing delivers completely reimagined consumer products,” said Uday Yadati, Global Head of HP Metal Jet at HP Inc. “Cobra’s commitment to innovation and competitive excellence, combined with the technical expertise and leadership from Parmatech, has led to a breakthrough design win for golf fans around the world.”

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Sliced logo on top of an image of fighter jets from the Hill Air Force Base. Photo via the Hill Air Force Base.