In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions in the additive manufacturing sector.

Today’s edition includes multiple new 3D printing partnerships, AM software updates, an overview of proper handling procedures for powder waste, and America Makes’ Executive Director John Wilczynski responds to the latest supply chain legislation from the US Senate.

Read on for the most recent updates from Post Process, Raise3D, Primus Aerospace, 3DS Outscale, Immensa Additive Manufacturing, Trumpf, Lantek, and more.

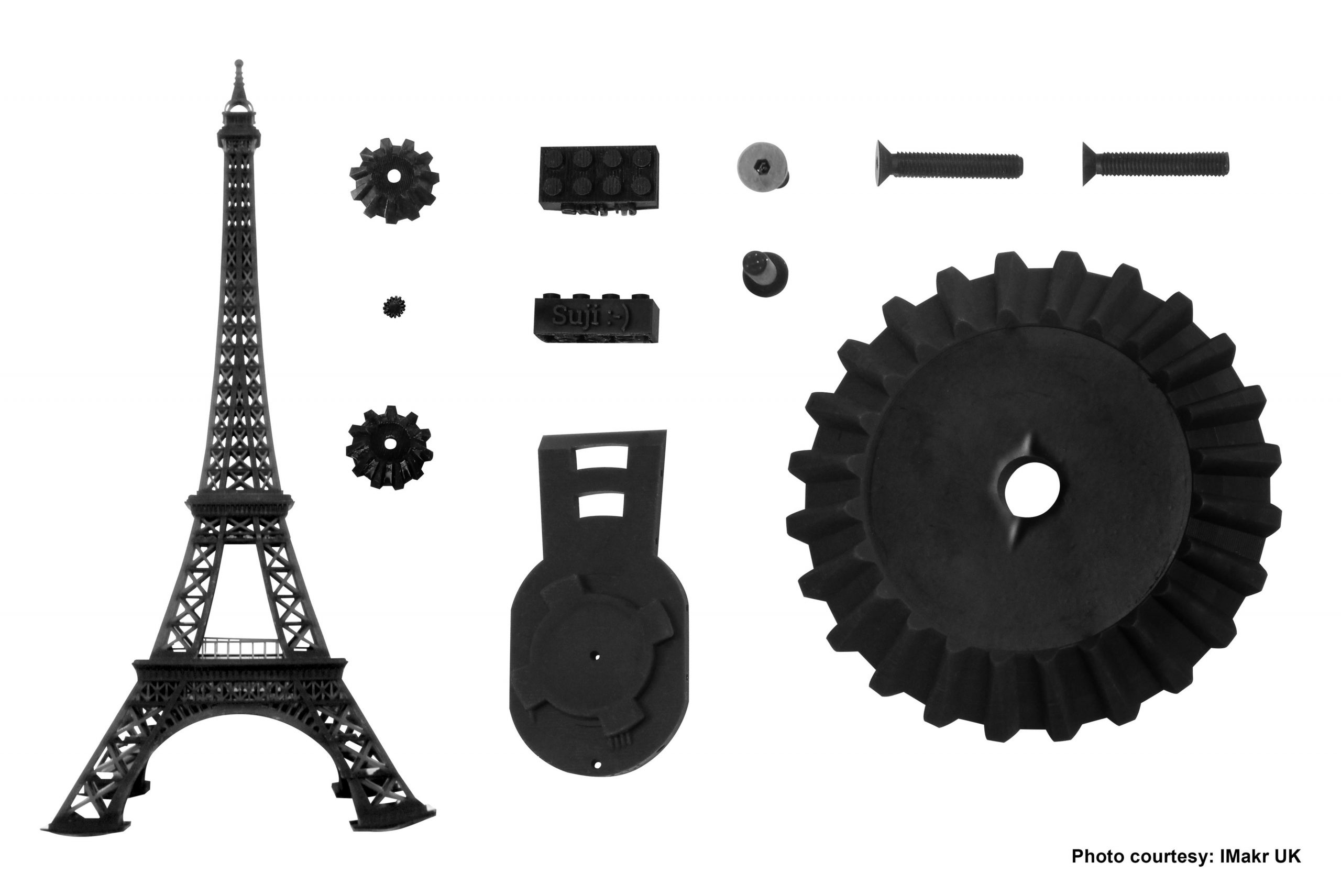

New 3D printing partnerships for PostProcess, iMakr, Sandvik, and Trumpf

Kicking off this week’s round-up is the news that automated post-processing system manufacturer PostProcess Technologies has partnered with global chemical firm Henkel to support companies in optimizing their resin 3D printing workflows through automated post-processing.

Henkel’s Loctite brand, which enables 3D printing applications in sectors spanning automotive, aerospace, engineering, and consumer goods, will now offer more validated cleaning solutions for its 3D printing resins, enabled by Loctite’s 3D Printing Workflow Tool which records print settings and post-printing cleaning and curing settings. The partnership will also see the two companies continue to develop further materials and technologies for photopolymer 3D printing.

“It’s exciting for us to cooperate with a renowned brand in the additive manufacturing space,” said Jeff Mize, CEO at PostProcess. “Much like Henkel, PostProcess keeps its eyes on not just one aspect of the additive process, but rather the entire end-to-end workstream. We’re looking forward to enabling Henkel’s future resin material developments with corresponding post-printing solutions that level up productivity and sustainability.”

Henkel has also joined forces with global 3D printer, scanner, and services reseller iMakr in a partnership that will see the latter supply Loctite 3D printing materials throughout the UK and Ireland, the US, Germany, Denmark, and France. As part of the agreement, iMakr will provide Loctite’s PRO410 professional-grade resin throughout its global network in addition to other ranges under the Loctite brand.

“We are pleased to be working with iMakr as they focus on education of the customer and matching the right solution based on the customer needs and objectives,” said Sam Bail, Director of Partnerships at Henkel. “At Henkel, we want to ensure customers realize the full potential of our materials.

“With their focus on customer support and product to application matching, iMakr is an ideal partner for us.”

In other partnership-related news, United Arab Emirates (UAE)-based 3D printing bureau Immensa Technology Labs has teamed up with global engineering group Sandvik and Italian additive manufacturing service bureau BEAMIT in a bid to advance additive manufacturing across the Middle East and North Africa (MENA) region. The partnership will leverage Immensa’s technical capabilities and position in the MENA region, and Sandvik’s materials technology, 3D printing processes, and metal powders, to increase the adoption of 3D printing throughout the area.

“We realize the big potential for additive technology in the MENA region,” said Kristian Egeberg, President of Sandvik Additive Manufacturing. “Through Sandvik’s 158 years of materials knowledge, and our strong expertise across the additive value chain – from metal powder to finished components – we look forward to help drive the implementation of additive manufacturing across a number of industries in the area.”

Elsewhere, German machine tool manufacturer TRUMPF has acquired Spanish sheet metal software developer Lantek in order to expand its sheet metal treatment and process chain capabilities. In addition to the acquisition, TRUMPF has also launched a new series of its TruPrint 3000 3D printing system which uses powder bed laser melting to produce parts up to 300 (d) x 400 (h) mm in size.

The machine is capable of handling weldable materials including steel, nickel-based alloys, titanium, and aluminum, and can be equipped with a second laser that almost doubles its productivity. The way inert gas travels through the machine has also been altered to boost the quality of printed parts and enable the removal of powder from a part while it is still inside the machine.

“We’ve improved key aspects of the TruPrint 3000 to tailor it even more closely to the quality requirements, certifications, and production processes of various industries,” said Klaus Parey, Managing Director of Trumpf Additive Manufacturing.

3D printer manufacturer SPEE3D rounds off this week’s partnerships update, having announced plans to install one of its WarpSPEE3D printers at the facility of El Salvador-based additive manufacturing service bureau, 3D in Metal. This marks Latin America as the latest region SPEE3D has entered with its WarpSPEE3D 3D printing systems, which utilize the company’s patented Cold Spray Technology.

Installing the WarpSPEE3D machine will enable 3D in Metal to meet demand for metal spare parts in the region, which often outstrips local capability.

“In developing regions spare parts can sometimes be difficult to source,” said Byron Kennedy, CEO of SPEE3D. “Though, with the WarpSPEE3D metal printer now at 3D in Metal for example, this can help leapfrog these regions to maintain their future supply and demand of metal parts much more easily.

“The installation in El Salvador just highlights the unique capabilities our easily deployable technology can bring to the region.”

3D printing software developments from Raise3D and 3DS Outscale

Moving onto the latest software news, 3D printer manufacturer and software developer Raise3D has launched the latest version of its slicing software, ideaMaker 4.1.0. New improvements to the software include a texture generation feature, which adds texture to a model’s surface based on a greyscale 2D image. The feature allows users to easily create different iterations of the same STL model by applying different patterns on its surface.

Further updates to the software include a new Texture Library offering users multiple textures from which to choose from, and a Belt Printer feature that gives the Y-axis an unlimited length to enable users to make longer objects or uninterrupted duplicates of a 3D model. Added support is also included for converting an imported image into a 3D model, alongside support for infills generated from the image, and nozzle modifiers.

Meanwhile, 3DS OUTSCALE, a Cloud subsidiary of 3D CAD software provider Dassault Systèmes, has established operations in Japan with the opening of a cloud region made up of two availability zones spread across three data centers around Tokyo.

The move will see 3DS OUTSCALE provide its main Cloud computing services and its catalog of on-demand services to the Japanese market, including customized virtual machines, storage services, virtual private cloud, and DirectLink services. The firm has established a local company, OUTSCALE KK, to ensure sovereignty and security according to local regulations.

“The adoption of Cloud computing and the strong growth potential of the Japanese market make it a very attractive hub for our customers in Asia,” said David Chassan, Chief Strategy Officer at 3DS OUTSCALE.

“3DS OUTSCALE is becoming a reference for European companies wishing to establish themselves in Japan and we are proud to act as a reference of the trusted Cloud in the land of innovation.”

Velo3D metal AM system purchased solely for aerospace and defense applications

Aerospace and defense contract manufacturing partner Primus Aerospace has purchased a titanium-dedicated metal additive manufacturing system from 3D printer manufacturer VELO3D, which it will use in the production of cube satellites, hypersonics, and turbo engines.

The Ti6Al4V Sapphire 3D printing system will be fully dedicated to fulfilling applications in the aerospace and defense sectors in order to achieve design and manufacturing capabilities for novel aerospace applications. Primus’ customers include the likes of Lockheed Martin, Boeing, Northrop Grumman, General Dynamics, and Raytheon, to name a few.

“Primus Aerospace is an excellent partner for us with their customer focus, commitment to innovation, and adoption of leading-edge technology,” said Benny Buller, Founder and CEO of VELO3D. “Our capabilities will help them deliver to engineers and supply chain managers the part designs they want, not the limited part geometries that other commodity-AM suppliers say they can have.

“The synergies between our two companies will support developers of new products to optimize their designs without compromise or restraint.”

Sintavia publishes disposable procedures for powder waste

Florida-based metal 3D printing service Sintavia has published an overview of proper handling procedures for powder condensate waste generated as part of the powder bed fusion (PBF) 3D printing process. Powder condensate refers to solidified particles resulting from the evaporation of metal alloys during PBF which are typically deposited into a collection chamber within the 3D printer or wet-vacuumed out of the build chamber.

As metal 3D printing enters maturity, powder condensate as a waste stream requires manufacturers to allocate proper resources for its safe disposal in line with environmental and safety regulations, according to Sintavia.

Ashley Wallace, Sintavia’s Quality and EHS Engineer, has written a paper in partnership with the Additive Manufacturer Green Trade Association (AMGTA) and Triumvirate Environmental titled, “Overview of Disposal Procedures for Powder Condensate Within Metal Powder Bed Fusion”, which lays outs procedures used in the US for analyzing and disposing of condensate from the PBF process, and real-world examples of how this can be done.

America Makes Executive Director applauds major supply chain legislation

Rounding off this week’s news is the introduction of new bipartisan supply chain legislation by US Senators to establish an office of Supply Chain Preparedness, offering a major shift in the approach to how the US manufacturing industry can respond to future crises.

Executive Director of the US 3D printing national accelerator America Makes, John Wilczynski, has applauded the legislation in a statement, underlining the need for a “comprehensive, national approach” to supply chain readiness, having praised US President Joe Biden’s executive order for mandating a review into the country’s supply chain dependency last month.

“With the White House’s renewed focus on manufacturing policy, this bipartisan supply chain legislation comes at the appropriate time to continue the conversation and establish an office of Supply Chain Prepareness to ensure our country is ready to respond appropriately to future scenarios and codify a lasting regulatory framework,” he said.

“Since the beginning of the Covid pandemic, America Makes and the additive manufacturing community have seen firsthand how critical regulatory clarification, capabilities mapping, and needs assessments are for a swift and effective response. Through this experience, our industry has been on the front lines, hard at work to develop a lasting road map for advanced manufacturing supply chains that can be used in times of crisis.

“This legislation is a welcome step in helping to set standards for supply chain readiness for the future of America.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a titanium fuel tank printed on a VELO3D additive manufacturing system with the Sliced logo.