In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions in the additive manufacturing sector.

Today’s edition features a COVID-19 event update, an international additive manufacturing contest, brand new biomaterials, a 3D printed antenna array and another small step towards STEM gender equality.

Read on for the most recent updates from Photocentric, Ultimaker, L’Oreal, PrintParts, ALM, innovatiQ, CoreTechnologie and more.

Humabiologics and ALM’s bio-material update

Kicking-off this week with material news, EOS subsidiary and polymer developer Advanced Laser Materials (ALM) has gained certification for the biocompatibility of its PA 650 material. Used widely by industrial Fortune 500 firms, the nylon-based feedstock now has ISO 10993 accreditation, meaning that it can safely be used within skin-contact applications such as surgical guides, splints and orthotics.

“This biocompatibility certification opens up an abundance of new and innovative 3D printing applications,” said Darin Chartier, VP of ALM. “We see the medical vertical becoming the biggest consumer of this material, but other industries have expressed similar interest, and we think this certification can be a difference maker getting ideas off the white board and into production.”

Regenerative medicine start-up Humabiologics, meanwhile, has launched what it describes as the “world’s first native human collagen and gelatin bio-inks.” Designed to provide an affordable means of advancing research into clinically-relevant bioprinted tissues, the company’s broadened offering now includes native human collagen and bone gelatin, as well as extracellular matrix product lines.

“We bridge the gap between donated human tissues and medical research by providing native human-derived biomaterials that are more clinically & physiologically relevant to develop new therapies,” Dr. Mohammad Albanna, CEO and Founder of Humabiologics told 3dpbm. “We provide products that have long been needed but unfortunately were not accessible to researchers.”

nScrypt and GE’s aerospace advances

Microdispensing specialist nScrypt has revealed that its Sciperio research arm has 3D printed a curved phased antenna array for the US Air Force Research Lab (AFRL). Built using nScrypt’s Factory in a Tool 3D printer back in 2016, the radar system is capable of ‘aiming’ signals rather than radiating them in all directions, providing the AFRL with a vital means of precision long-range communication.

Through the project, the AFRL has worked with nScrypt and Sciperio to develop more complex multi-layer RF electrical structures for printing on doubly-curved surfaces, as well as extending and debugging its modelling and simulation tasks, addressing interconnects and combining its digital workflow and manufacturing processes.

“Printing complex electronics is always challenging. Doing so on a curved surface extends that challenge,” said Ken Church, CEO of nScrypt and Sciperio. “The nScrypt and Sciperio teams have been printing electronics for more than 20 years, and their recent prints of complex electrically functional curved structures demonstrate the power of 3D manufacturing for 3D printed electronics.

“High value functional electronics demand precision, material performance and multiple material options, and multiple manufacturing processes, all performing in three dimensions, which is our sweet spot.”

In similar news, General Electric’s (GE’s) aviation division has announced that an F110 engine sump cover, that it 3D printed as part of its Pacer Edge pathfinder program, has gained U.S. Air Force (USAF) certification. The USAF Engineering Change Proposal (ECP) approval, which is the first of its kind to be issued, concludes the project’s first stage, but the organizations are already planning their next print: a TF34 housing.

“The Pacer Edge program is an important initiative for reducing risk and showcasing the application of additive manufacturing in aerospace,” said Nathan Parker, Deputy Program Executive Officer for the USAF RSO. “The ability to additively manufacture an aircraft engine part and gain military airworthiness is a significant step forward in growing the adoption of additive manufacturing in the Air Force.”

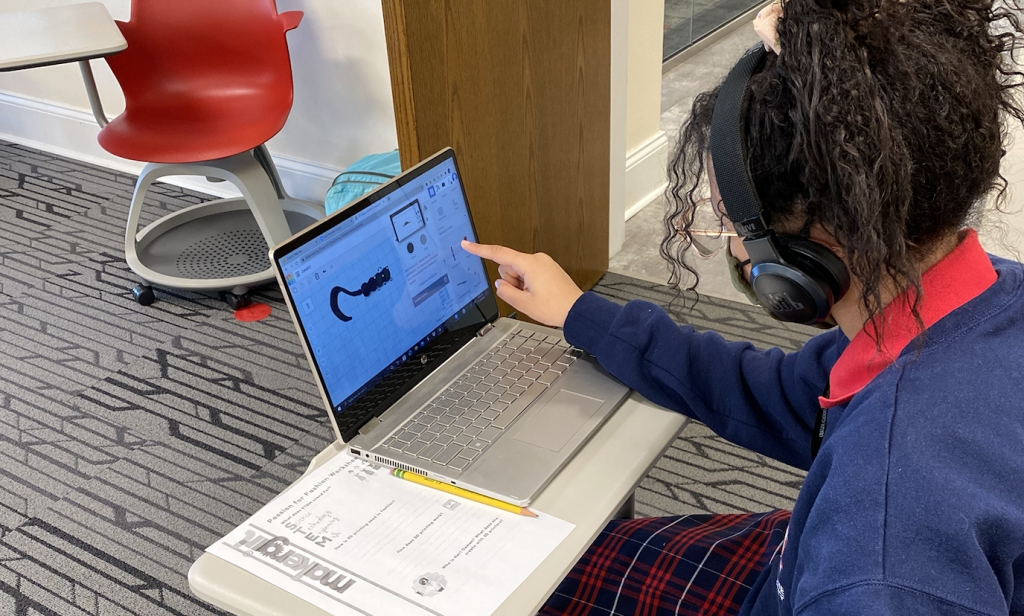

PrintParts backs MakerGirl initiative

3D printing service provider PrintParts says that it has become a “proud sponsor” of the non-profit MakerGirl organization. Set up to bridge the gender gap in STEM (science, technology, engineering, and math) by introducing young girls to 3D printing at an early age, MakerGirl has had to go digital since the pandemic’s outbreak, which has prevented in-person teaching across the U.S.

Despite this, the group still managed to deliver a total of 93 virtual sessions to 566 young girls across 28 different states and 3 additional countries during 2020, and looking ahead to the rest of 2021, it now aims to double its impact by providing education to 1,000 students completely free of charge, thanks to the backing of firms such as PrintParts.

“Throughout this unprecedented time, MakerGirl has been able to create virtual educational experiences that have allowed girls to continue their STEM education,” said Mary Hadley, CEO of MakerGirl. “During this transition to the new normal, MakerGirl will continue to grow, reach rural areas, and educate girls of all backgrounds. We are so grateful for PrintParts support to make this possible.”

Mixed news on 3D printing trade shows

The organizers of the 3D Print Congress and Exhibition have announced that they’re adding a second location to their Lyon event from October 20-21 2021 due to popular demand. Held annually as a means of showcasing the potential of 3D printing to industry, the trade show is designed to provide attendees with the opportunity to network, innovate and consolidate projects.

Due to take place in Paris, the second free-to-enter conference is set to feature AM award ceremonies, machine demos, training opportunities and case studies on developing best practice from industry leaders including EOS, HP, Multistation, BASF, Materialise, CadVision, Altair, Joke Technology, Erpro, Linde Gas, Rosler and more.

By contrast, the team behind the East Coast Rep Rap Festival or ‘ERRF’ have decided to cancel this year’s event. Citing a lack of interest from exhibitors, and travel complications caused by COVID-19 restrictions, ERRF’s organizers say that they’re not willing to hold a “half-empty” show or “convince people to participate in an in-person event” if they’re not comfortable, hence they’re now focused on 2021.

“While we know this is going to be disappointing to some, this is the right decision for where we are right now for ERRF,” commented the ERRF team. “When it comes to the safety of our community, and even ourselves, we believe it is better to err on the side of caution. Our next in person ERRF event will be ERRF 2022, and we will start planning that event early next year.”

Teton Simulation joins software program

3D printing software developer Teton Simulation has announced that it has agreed to join the GrabCAD Software Partner Program. The move will see the firm’s SmartSlice software become the first to utilize Stratasys’ new GrabCAD DFAM Software Development Kit (SDK), which allows users to iteratively improve upon the reliability of their 3D printed builds.

As part of the companies’ partnership, SmartSlice will effectively be released as a plug-in for the GrabCAD Print workflow software, streamlining the validation and optimization of FDM print parameters, while providing users with confidence that their parts will meet functional and performance requirements and yield minimal material waste.

“Being able to validate as-printed performance, and minimise print times and material use all within the user’s current workflow, is at the core of our strategy,” said Teton Simulation CEO Doug Kenik. “We are excited to announce that one of our next line of offerings outside of Ultimaker Cura will be with Stratasys, as their first ‘Design for Additive Manufacturing’ (DfAM) Software Partner.”

“As AM continues to push into production workflows through machine and material innovations, software will help to drastically reduce cycle times and instil confidence that the printed part will function as desired.”

Business news from SPEE3D, Sigma Labs and more

Starting this week’s business roundup with 3D printer manufacturer SPEE3D, the Australian firm has announced the sale of one of its LightSPEE3D Cold Spray machines to Penn State University. As a U.S. department of Defense (DoD)-designated research center, Penn State is now set to host research into the advancement of U.S. 3D printing equipment, led by Tim Eden, Ph.D, alongside NAVSEA’s Janice Bryant.

“Our collaboration with SPEE3D is an excellent addition to our current capabilities in Metal AM and Cold Spray,” explained Eden. “We are looking forward to developing and applying SPEE3D technology to meet the materials and manufacturing challenges of the U.S. Navy, DoD and the industrial base.”

Quality assurance software developer Sigma Labs, meanwhile, has been added to Russell Microcap Index as part of its annual reconstitution. Effective June 28 2021, the company joins an index which is often used by investors as a basis for future strategies, and $9 trillion in assets are currently benchmarked against it in the U.S.

“The inclusion of Sigma Labs to the Russell Microcap Index will enable greater access and visibility to institutional investors and investment managers,” said Mark K. Ruport, President and CEO of Sigma Labs. “We are moving forward on multiple fronts on our internal roadmap with a strengthened balance sheet, a growing customer base, and a robust outlook for the 3D metal printing market.”

“Our team’s hard work and dedication have brought us to this point, and I believe we are well-positioned to continue building momentum and drive value as the market accelerates.”

Over in France, 3D printing bureau Multistation has signed a deal with 3D printer manufacturer innovatiQ to become the country’s exclusive distributor of its silicone printing products. The agreement sees it ship InnovatiQ’s LiQ320 machine, which is capable of producing functional parts without post-processing, that have properties similar to those of silicones produced via injection molding.

Elsewhere, software specialist CoreTechnologie has partnered with UK 3D printer and materials manufacturer Photocentric to develop a program that’s specifically designed to optimize the performance of its machines. Using an API interface, Photocentric systems can now be connected directly to CoreTechnologie’s software, allowing for the seamless transfer of CAD and STL files.

The companies have also developed a new module that enables users to create support structures that are built exclusively for use with Photocentric machines, providing adopters with a high level of automation, while the platform’s catalogue of 5,000 textures allows them to get creative with more unique designs.

Third AM Cup competitors confirmed

Finishing with a competition update, the third edition of the international Additive Manufacturing (AM) Cup has been confirmed. Backed by Solvay, L’Oréal and Ultimaker, the contest is designed to give students, engineers and manufacturers the chance to show their aptitude for creating innovative 3D printed designs that address real-world applications.

Entrants must use one of Solvay’s materials to create their entry, and register their interest in participating by September 30 2021, with the competition set to run until November 1 2021. Due to be crowned in January 2022, the winner will receive €5,000 from Solvay for “academic, societal or entrepreneurial activities,” as well as an Ultimaker 2+ Connect 3D printer and a tour of L’Oréal’s production facilities.

“Solvay’s AM Cup was introduced to showcase Solvay’s array of AM-ready filaments and their potential for diverse complex industrial uses,” explained Brian Alexander, AM Global Product & Application Manager at Solvay. “We are pleased to collaborate with L’Oréal who offer a tangible and challenging industrial application, and partner with Ultimaker to 3D print our candidates’ designs for assessment.”

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper-dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, de-briefs and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Sliced logo on top of a robotic arm used within L’Oreal’s manufacturing process. Image via Solvay.