In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions in the 3D printing sector.

Today’s edition includes several 3D printing partnerships, a new biocompatible photopolymer resin, a set of 3D printing competitions and awards, and new university-level 3D printing courses.

Read on for the most recent updates from SLM Solutions, SMARTTECH3D, Evatronix, Index Group, MacLean-Fogg, 3D Hubs, ABCorp and more.

New partnerships in 3D printing

We kick things off with a new partnership between 3D scanner manufacturer SMARTTECH3D and metrology software developer Verisurf. The deal will see Verisurf’s 3D measurement software integrated into SMARTTECH3D’s scanning devices, enabling users to better gather precise 3D part data for quality control and reverse engineering projects. The new collaborative software suite will include three modules: CAD, ANALYSIS, and REVERSE.

Anna Gebarska, Managing Director of SMARTTECH3D, said, “Our high-resolution structural light scanners are focused on collecting precise geometry and color data. When it comes to processing and analyzing that data, we feel Verisurf provides the most comprehensive set of applications, all of which are based on a powerful CAD platform. This is both unique and extremely customer-focused.”

Elsewhere, Polish 3D scanner OEM Evatronix recently signed a distribution agreement with 3D printing service provider Canadian Additive Manufacturing. The agreement is set to expand Evatronix’s reach to Canada, where the company’s eviXscan 3D scanner range will now be made widely available.

“We are very excited to incorporate a top of the line structured light scanner for metrology applications into our portfolio,” says Jason Podger, Managing Director of Canadian Additive Manufacturing. “Evatronix’s products are high-end equipment at a competitive price. After receiving the eviXscan 3D Heavy Duty Quadro scanner, we were very impressed with the quality of data we can get from it and how well built the product is.”

Binder jet 3D printer OEM ExOne recently announced a partnership with Aurora Group and two of its subsidiaries to expand the reach of the company’s 3D printing technology in Asia. The deal will see General Integration Technology (GIT) in Taiwan and Aurora 3D in China become ExOne’s latest authorized channel partners. With these additions, ExOne has doubled its representation in Greater China in the past year alone, increasing the company’s APAC sales partner total to 12.

“GIT and Aurora 3D have deep experience with 3D printing software and hardware as well as a sales network to successfully identify companies that can benefit from binder jet technology,” explains Ben Leung, ExOne Vice President, Asia. “We are excited to work together to further promote the adoption of additive manufacturing through our portfolio of machine solutions.”

Acquisitions in additive manufacturing

MacLean-Fogg Component Solutions, a developer of fasteners, has announced the acquisition of 3D printing materials developer Formetrix. The new business entity will go forward under the name of MacLean Formetrix, with MacLean Fogg now able to use Formetrix’s metal powder intellectual property to service OEMs and tool and die makers in the automotive, agriculture, and heavy industry sectors.

Duncan MacLean, MacLean-Fogg’s President & CEO, adds, “As a previous customer of Formetrix, we were able to implement technical cost break-throughs with their material and process innovations that others in the additive manufacturing business claimed were impossible. We couldn’t be more excited to continue to make their innovations available for our internal users, as well as serve other innovative manufacturers and tool makers.”

Finally, manufacturing system provider Index Group has acquired a majority interest in TRUMPF’s One Click Metal, a developer of industrial 3D printers. Having founded One Click Metal in April 2019, TRUMPF will remain an active and strategic partner, supporting the development of the company alongside Index. More importantly, the deal will provide One Click Metal with additional capital to continue its growth as a metal 3D printer OEM.

Business developments from 3D Hubs, ABCorp, and Oerlikon

On-demand manufacturing firm 3D Hubs has rebranded itself to Hubs. According to the company, the new name is designed to better reflect the wide range of manufacturing services it now offers, marking its position as a leader in custom part production. As well as 3D printing, the Hubs offering includes CNC machining, sheet metal fabrication, and injection molding.

Bram de Zwart, CEO and co-founder of Hubs, adds, “COVID-19 and the resulting supply chain disruptions have accelerated the manufacturing market’s need to embrace supply chain resilience and efficiency. Hubs has been at the forefront of this movement from the beginning, by creating pricing transparency, a globally distributed manufacturing partner network and smart routing of customer orders within this network.”

The American Banknote Corporation (ABCorp), a manufacturing service provider specializing in payment devices, recently expanded its 3D scanning and post-processing capabilities. Specifically, the company’s Boston-based Additive Manufacturing Center (AMC) now houses a SolutionIX C500 structured light scanner, along with a Girbau DY130 part dying system compatible with HP MJF 3D printed parts.

Neil Glazebrook, VP of 3D Solutions at ABCorp, explains, “Similar to qualifying an injection mold, we can dial in the MJF 5210 process to a customer’s needs through printing, inspecting, and modifying the model and deliver unparalleled part quality in a highly secure environment. And dyeing is an industry staple for MJF parts, but can be messy and inconsistent. The Girbau DY130 allows us to offer an automated dying system with superior and consistent quality at a competitive price.”

Elsewhere, in Switzerland, additive manufacturing technology provider Oerlikon recently placed three series of senior unsecured bonds totalling 575 million Swiss Franc ($633,114,000). 125 million Swiss Franc (CHF) are due in November 2022, 250 million CHF are due in November 2025, and 200 million CHF are due in November 2028 – the offering has reportedly attracted broad investor demand.

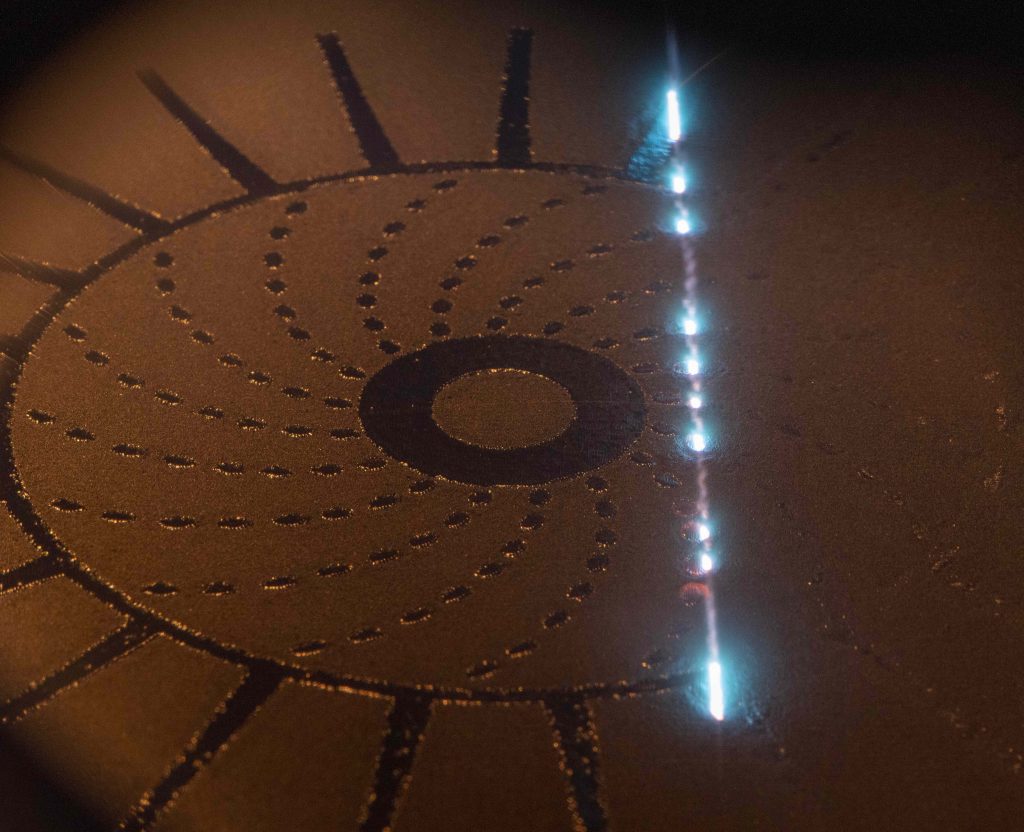

Wayland sells its first Calibur3 3D printer

UK-based metal 3D printer OEM Wayland Additive has announced the first sale of its new Calibur3 3D printer to engineering consultancy Exergy Solutions. The system operates on Wayland’s NeuBeam process, the company’s take on electron beam powder bed fusion. NeuBeam is capable of neutralizing the charge accumulation that tends to occur with other electron beam technologies such as electron beam melting (EBM), resulting in a wider range of viable print parameters and increased material flexibility.

Peter Hansford, Director of Business Development at Wayland Additive, states, “We are extremely pleased with the response to the launch of our Calibur3 machine, and to be able to announce our first sale to Exergy is very exciting. We are in advanced discussions with a number of companies interested in our ground-breaking metal AM process, all of which recognise that NeuBeam affords them access to numerous production alternatives.”

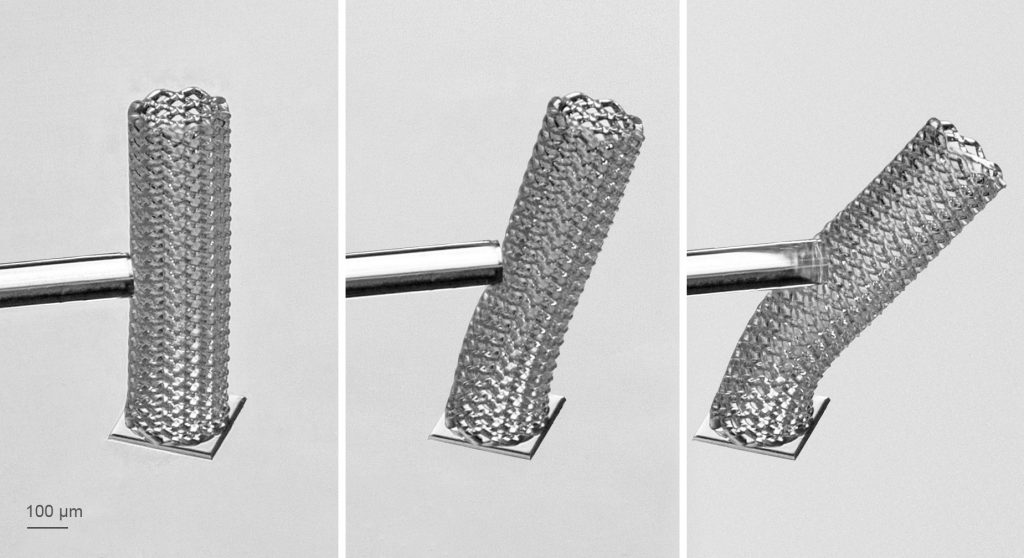

Nanoscribe launches new elastomeric 3D printing resin

Nanoscribe, a provider of microscale 3D printing technology, has launched its new IP-PDMS photoresin. The silicone-based material is biocompatible, and features a combination of flexibility, softness, and elasticity. With potential applications in life sciences, microfluidics, and microelectromechanical systems (MEMS), the new material offers a Young’s modulus of 15.3MPa and can be stretched by up to 240%.

“In our initial tests for 3D printing soft polymeric structures, IP-PDMS turned out to be a promising material,” says Ada-Ioana Bunea, Assistant Professor at the Nanolab of the Technical University of Denmark. “Personally, I am excited to exploit the new resin for microrobotic components and biomimetic scaffolds.”

3D printing education with Karlsruhe University and ASME

The Karlsruhe University of Applied Sciences (HsKA), located in Baden-Württemberg, Germany, has begun delivering advanced engineering training using 3D printing technology developed by MakerBot. The university’s Additive Design and Manufacturing Lab has just been equipped with a METHOD X 3D printer, which will be used to teach students the foundations of generative design and additive manufacturing. Through several courses, engineering students will learn how to conceptualize, design, and transform their ideas into functional parts.

Dr. Florian Finsterwalder, a Professor at HsKA, states, “I believe that 3D printing is a valuable problem-solving tool and key competency for the future workforce. It was important to integrate this technology into our courses to give students a chance to use equipment that is currently being used within design and manufacturing companies today.”

Elsewhere, standards organization ASME has announced a new virtual AM Tech Forum featuring a ‘crash course’ in the latest additive manufacturing technologies. Set to take place on June 17, the event will include up to 30 new product demonstrations, as well as an AM Innovation Awards ceremony to help 3D printing professionals keep up to date with the latest developments in the industry.

“It’s difficult to keep up to date in this field with the number of mergers and acquisitions, the speed of new technology development, and new product launches,” says Debbie Holton, ASME’s managing director of industry events. “Engineers and manufacturers in a variety of industries need to know what’s available, what their options are, and they want to see the equipment.”

Competitions and awards in additive manufacturing

FFF 3D printer manufacturer BCN3D has won one of this year’s iF Product Design Awards for its large-format Epsilon 3D printer. Submitted among almost 10,000 entries from 52 countries, the Epsilon was selected by a judging panel of 98 members, all of which are design experts from around the world. The system features a build volume measuring 420 x 300 x 220mm and BCN3D’s signature IDEX FFF setup.

Fermin Monreal, a product designer at BCN3D, states, “My design process is based on a very famous methodology called design thinking. It’s quite a common theory but, for me, the true skill lies in knowing how to adapt that methodology to each particular project. For example, the needs of a hardware product, such as a printer, are very different from a software product, such as an operating system interface.”

Elsewhere, at a 3D Printing Housing Hackathon organized by construction firm LafargeHolcim, a Danish architectural team won with a concrete design printed on a COBOD BOD2 3D printer. The 6-month competition included 66 participants, with the first prize going to Nexus Void from the Royal Danish Academy from Architecture (KDK) and the Technical University of Denmark. The printed wall structure featured thermal insulation, ventilation, and a place for load-bearing columns to be integrated.

Helene Lombois-Burger, Digital fabrication R&D Project Manager at the LafargeHolcim Innovation Center, adds, “The jury was impressed by the quality of the projects, with amazing concepts in terms of innovation, strongly documented and prototyped.”

Finally, industrial 3D printer provider SLM Solutions recently launched its new ’Print the Future’ competition. The design contest is an open call to artists, designers, and engineers to design parts for metal 3D printing. Entries can be anything from functional prototypes to artistic pieces, but it has to be original and it has to be 3D printable. The competition closes on 21 May and the winner will be selected by the end of the month, after which the winning part will be 3D printed by SLM Solutions.

“The point of the competition is to open up metal-based additive manufacturing to those not normally able to take advantage of it,” says Sam O’Leary, SLM Solutions’ CEO. “To many, additive manufacturing is seen as something unreal. However, it’s a future that has already arrived at the doorstep of many sectors and is disrupting traditional manufacturing as we speak. We are now setting a new paradigm.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Sliced logo on an image of the Calibur3’s powder bed. Photo via Wayland Additive.