In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions in the additive manufacturing sector.

Today’s edition features the latest on this year’s Formnext, a fully-3D printed rocket debut, ancillary and machine launches, several 3D printed homes and more on the future of the technology in the cutting-edge world of Formula 1.

Read on for the most recent updates from Relativity Space, SPEE3D, ASTM International, COBOD, Meltio, MakerBot, CORE Industrial Partners, Tekna, BOFA Americas and more.

Formnext Start-up Challenge extended

Beginning this week’s update with the 3D printing industry’s leading European trade show, Formnext has announced that the deadline for applications to the 2022 Start-up Challenge and AM Ventures Impact Award has now been extended.

Whereas submissions for the two awards were set for 1 July, 2022, they’re now due by 8 July, 2022, giving applicants another week to prepare their entries. While the former contest continues to attract applications from start-ups honing innovative technologies with significant commercial potential, the latter is focused largely on recognizing those using 3D printing to address sustainability issues.

“The potential offered by additive manufacturing for addressing the major global sustainability challenges is significant,” says Arno Held, Managing Partner at AM Ventures. “The technology can be used to make drives more efficient, minimize material consumption, accelerate repairing cycles and extend battery ranges. In all areas, AM can improve the world if we use the technology correctly.”

Y Soft, ASTM make certification advances

Next up, in the world of 3D printing certifications, standards developer ASTM International has launched a program that’s designed to make it easier to bring new technologies to market. Known as ‘ASTM Xcellerate,’ the initiative is set to make sure that those developing novel processes, embed standards at the very start of R&D, in a way that minimizes their costs and any chance of research duplication.

“The standards value chain starts way before a standard is published. Before, we thought of standards as coming at the end of the technology-development process,” said Brian Meincke, ASTM’s VP for Global Business Development & Innovation Strategy. “Through Xcellerate, we’re seeing R&D and standards communities becoming more aligned, and standards starting to be developed in parallel with R&D.”

At Y Soft, meanwhile, the enterprise office solutions provider has achieved ISO 27001:2013 certification. For those unfamiliar, the standard covers the establishment, development and maintenance of a data security management system. The firm says becoming certified shows that it takes clients’ information security seriously, and it’s “committed to meeting their expectations to keep them safe.”

Relativity Space nears take-off debut

Moving onto aerospace news now, Relativity Space’s 3D printed Terran-1 rocket is rapidly approaching its first attempted orbital launch. Although the firm’s CEO Tim Ellis has said himself that its test is around two years behind schedule, the launch vehicle is now said to have been delivered to its ‘LC-16’ Cape Canaveral launch pad.

As of last week, Relativity Space was said to still be planning to conduct final booster qualification testing, including its first all-engine, full-power static fires. That said, the rocket passed upper-stage testing with no reported faults, and if its booster-stage qualification goes as well as this, it could be flight-ready as early as this summer, in Q3 2022.

Advances in construction 3D printing

Over in the emerging construction 3D printing sector, COBOD has announced a distribution partnership with nidus3D. Having recently deployed the BOD2 to build four 560 square foot housing units in Canada, nidu3D is now set to act as a COBOD distributor in the country, in a move that could strengthen adoption of the technology in North America.

“The BOD2 is an industry-leading construction printer that outstrips competitors in its versatility, scope and durability,” said Ian Arthur, President of nidus3D. “nidus3D is actively deploying 3D construction printing technology (3DCP) to lower building costs and expand access to resilient, efficient and sustainable housing while complying with Canadian building standards.”

“The opportunity to work with COBOD, world leader in 3DCP is incredible.”

In Angola, meanwhile, Power2Build has utilized its own BOD2 to build its second 3D printed home in the country, complete with suite, bedrooms, bathrooms, dining room and a living room. Using the system, as well as a D.fab concrete developed by COBOD and CEMEX, the firm is said to have been able to reduce its spending on materials by up to 90%, and showcase the process’ affordable housing potential.

“We are very proud of our progress. People were questioning if we could print bigger. We have now printed a 2.6 times bigger house and in about two-thirds of the time compared to the first house,” said Power2Build CEO Ricardo Almeida. “We improved the speed of execution remarkably, but still believe there is room for improvement. In future, we will only become better at mastering this technology.”

Lastly in the concrete additive manufacturing industry, Virginia Housing has announced the sale of the state’s first 3D printed home. Featuring 1,550 square feet of living space, the build has been bought by Richmond resident Tiffany Terrell, for herself and her 14-year-old daughter to live in. With a final selling price of $235,000, it’s thought that the low-cost home could now be the first of many sold in Virginia.

“I didn’t know anything about 3D printing. I came to see it when it was bare-bones. It looked like a brand-new house,” Terrell told the Richmond Times Dispatch. “I did my research after that and thought, ‘this is pretty cool.’ When you find what you want and it’s got everything you wanted, it’s great.”

Sauber to continue 3D printing F1 parts

Sauber Technologies and Alfa Romeo F1 Team ORLEN have announced a three-year extension to their partnership with Additive Industries. Over the last five years, Sauber Technologies has used its partner’s MetalFAB system to reduce the time it takes to produce parts for wind tunnel models and F1 cars, as well as its third-party business. Working together, the firms say they “aim to keep pushing boundaries in metal AM to manufacture lightweight crucial components.”

“Over the course of our successful partnership, Additive Industries have become an essential ingredient in the offering of Sauber Technologies,” explains Christoph Hansen, COO of Sauber Technologies. “Additive Industries continues to provide us with the best way to manufacture the most advanced parts for our motorsport operations, as well as our growing cohort of customers, reducing lead times, costs and waste while pushing forward the boundaries of technology.”

“Ever since we introduced the MetalFAB systems to our processes, our in-house capabilities have increased in a significant way.”

CORE Industrial Partners’ expansion ramps up

Private equity firm CORE Industrial Partners has acquired prototyping service provider GoProto, just five months after buying service bureau RE3DTECH. Having wrapped up the deal, the firm says it intends to combine its subsidiaries, to form an “AM platform focused on production parts utilizing Industry 4.0 capabilities.”

According to Matthew Puglisi, a Partner at CORE Industrial Partners, the move also provides it with a “large base of industry-leading customers, deep manufacturing expertise and a talented leadership team.” In particular, Puglisi believes that GoProto’s extensive in-house multi-jet fusion offering is “uniquely suited to serve the expanding market for higher-volume additive production.” As such, he said that his firm is now looking forward to using its experience to “expand the platform.”

BCN3D, Meltio build out reseller networks

Spanish 3D printer manufacturer BCN3D has expanded its reseller network in India via a new partnership with Shree Rapid Technologies (SRT). BCN3D says the move will help provide manufacturers in the country with access to a technology that “drives innovation, doubles productivity, cuts costs and streamlines their workflows.”

“SRT decided to partner with BCN3D for several reasons,” explained Shree Rapid Technologies Partner Nitin Chaudhari. “As a leading 3D printing solution provider in the Indian market, BCN3D was our obvious choice. With BCN3D being the pioneer of the IDEX technology in desktop 3D printing, we are sure that we’ve partnered with one of the top leaders in the desktop 3D printing market.”

“With BCN3D being a trusted brand globally in the engineering, automobile and consumer goods industries, as well as the service bureau market, we can now offer industrial professional desktop 3D printing in India.”

Likewise, metal 3D printing technology developer Meltio has built its distribution network out into Australia for the first time, by naming Metal Tech as an Official Sales Partner. In its new role, Metal Tech will focus on building a supportive ecosystem for Meltio’s technology in the country, by seeking out opportunities in technology centers, tooling firms, robotic integrators, academia and industry.

Stratasys technologies drive new use-cases

In the first of two Stratasys-enabled innovations in this week’s application update, luxury pen manufacturer Il Pennaio has used one of its J Series Polyjet systems to relaunch the historic Duchessa 1935 brand. Using the technology alongside fashion brand Florenradica, the firm has managed to develop pens with a new range of designs, featuring previously-impossible color combinations and intricate patterns.

Already, just weeks after the brand relaunched, it’s said to have ‘delivered an influx of new customers’ to Il Pennaio, boosting its sales, while thanks to the quality of the products’ end-designs, the collection has also seen the firm selected to become a partner of La Couronne du Comte, one of the largest pen manufacturers in Europe.

“Stratasys’ resins are completely different and novel for this market, opening up new possibilities and changing the way in which we approach design,” said Fabio Moricci, Co-owner of Il Pennaio. “By fully-exploring the color and material combinations made possible with Stratasys’ technology, we have been able to deliver something fresh, exciting and truly innovative, revitalizing a market which has previously felt stagnant.”

Stratasys subsidiary MakerBot, meanwhile, has announced the donation of more SKETCH, METHOD X and Replicator+ 3D printers (as well as the materials needed to run them), to low-income US communities. By providing access to the technologies to students who otherwise wouldn’t have the funding to do so, the firm aims to help underrepresented groups become more active in STEM subjects.

“The impact of 3D printing really dwells in the power and capability it has to spark the imagination and creativity of our students,” said Kristen Goodwin, a 3rd Grade Teacher at Kihei Elementary School, one of the recipients of MakerBot systems. “This is where the magic of art, science, and design meet to develop solutions for everyday problems. The use of SKETCH 3D printing can usher in technology integration into virtually any lesson inside our classroom.”

Tekna, 3D Systems push material boundaries

When it comes to 3D printing materials, Tekna has taken a significant business step this week, after agreeing to supply Uniformity Labs with titanium powders. As part of the deal, Tekna is set to provide Uniformity Labs with Ti64 5/25 and Ti64 45/105, which in turn, will use these to produce materials for Powder Bed Fusion clients.

Moving forwards, the companies also intend to work together as a means of increasing Tekna’s output capacity and efficiency, in a way that helps “make available a critical North American supply source” of titanium powders.

US 3D printer manufacturer 3D Systems has made similar advances with its material portfolio as well, having entered into a strategic partnership with EMS-GRILTECH. The companies’ collaboration has already yielded a novel Selective Laser Sintering (SLS) 3D printing nylon copolymer known as DuraForm PAx Natural, which is said to feature similar properties to injection molded plastics.

With a low processing temperature of 120°C, the material is designed to be much quicker to print and post-process than other nylons, and allow service bureaus to reduce their related lead times. DuraForm PAx Natural is also being marketed as having impressive long-term stability, in both mechanical properties and color, potentially lending it outdoor use cases such as ducting or liquid reservoirs.

“We’re very excited to be able to collaborate with EMS-GRILTECH in a way that allows us to not only advance our innovation roadmap but also advance materials performance for the industry,” claims Dr. Edwin Hortelano, Senior VP of Materials Engineering & Development at 3D Systems. “With DuraForm PAx Natural, we’re not only bringing a superior product with leading mechanical properties, we’re also delivering a new material for use with any SLS printing technology, which we intend to expand to other powder-bed fusion platforms.”

SPEE3D, BCN3D, Würth issue hardware updates

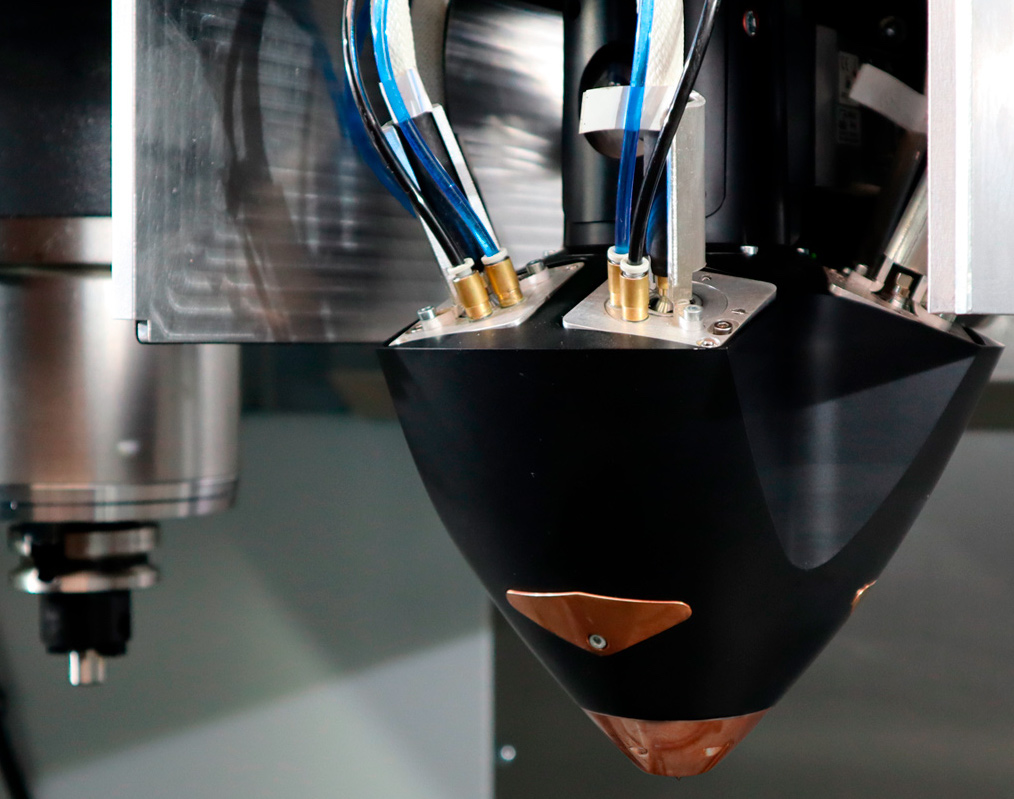

Finishing this week’s digest with a spate of hardware upgrades, metal 3D printer manufacturer SPEE3D has launched a new, ultra-high-energy nozzle for its systems. Using compressed air or nitrogen, the printhead is able to deposit material four times faster than the speed of sound, in a way that enables greater particle deformation during deposition, and makes it compatible with harder metals.

Similarly, the Würth Additive Group has also unveiled a partnership with BOFA Americas, a subsidiary of the fume extraction and filter technology developer BOFA International. The deal will see the Würth division integrate BOFA filtration units into the 3D printers it supplies, thus enabling its clients to engage in ‘workplace atmosphere management.’

“BOFA is able to help support our customers’ strategy to promote safety and a more pleasant working environment around a variety of our equipment,” explained AJ Strandquist, CEO of the Würth Additive Group. “Our partnership will make it easier for customers to find everything they need in one place. Now the air you breathe isn’t an afterthought; it’s a part of the discussion from the start.”

In another BCN3D announcement, meanwhile, the Barcelona-based firm has revealed that it’s set to ship twenty Viscous Lithography Manufacturing (VLM) systems in Spring 2023. While the company began rolling out local operations in North America in late 2021, its first commercial units will be delivered to members of its Technology Adoption Program, an initiative set up to identify VLM applications.

“The overwhelming initial reception for our most recent innovation has surpassed our expectations,” said Xavier M. Faneca, CEO of BCN3D. “We’ve been able to hone in on what really matters to each individual company by gathering real, tangible information from experienced engineers. We’re aware of special interest regarding multi-material, and thus multi-property and water-soluble applications.”

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Formnext 2021 trade show venue with the Sliced logo. Photo by Michael Petch.