In this latest edition of the 3D Printing Industry news digest Sliced, 3D printing is providing care to the afflicted in Syria; the latest iteration of a premier motorsport racing car is realized with additive manufacturing; and further strides are made towards developing standards in the aerospace industry.

Read on for updates from the likes of Siemens, Farsoon, HP, WASP, Wipro 3D, BCN3D Technologies, BIOLIFE4D and more.

Award-winning additive manufacturing materials

In the recent batch of material news, Filkemp, a Porteguese-based filament manufacturer, has signed a distribution partnership with British 3D printing reseller GoPrint3D. GoPrint3D will market, stock, and distribute filaments for Filkemp to customers in the UK. The filaments on offer include PLA-N, Nylon and PET-G. The addition of Filkemo’s filaments to GoPrint3D’s portfolio follows recent news that the company had added HP’s MJF 3D printers to offering of 3D printers as well.

Netherlands-based 3D printing material manufacturer Liqcreate has released a new resin aimed towards the manufacturing of dental and aligner models. Called the Liqcreate Premium Model, it is an accurate, low shrinkage resin with a matte, opaque skin/peach color. The material is compatible for use with LCD and DLP 3D printers.

French metal processing specialist Aubert & Duval and UK-based alloy development company OxMet Technologies have entered into a partnership agreement for the production and distribution of one of Oxmet’s materials for additive manufacturing. The material in question is the compay’s ABD-XAM range of high-strength and high-temperature printable nickel-base powders, designed specifically for 3D printing. In early 2019, Aubert & Duval had also signed an additive manufacturing powder production deal with Canadian plasma specialist PyroGenesis.

Olivier Dubois, VP Business Line Powders for Additive at Aubert & Duval, commented: “Additive manufacturing is a unique and innovative process, and to unlock its true potential, new materials are required. With this partnership, Aubert & Duval brings to its customers two new high-performance alloys designed for additive manufacturing. We are excited to see what they will create.”

colorFabb, the Netherlands-based 3D printing materials company is now offering selected iglide filaments from igus, an international advanced polymer supplier, through its webstore.

Swedish materials manufacturer VBN Components has revealed that its cemented carbide Vibenite 480 material for 3D printing has won the MM Maschinenmarkt’s innovation award in the category of Additive Manufacturing. The awards were presented during EMO Hannover, with categories surrounding machine tools, additive manufacturing, precision tools, software, production and process automation, measurement technology and quality assurance.

DfAM for Aerospace

In aerospace, Airbus Helicopters in Bavaria has adopted the use of an automatic KASTOwin amc bandsaw from German sawing machine manufacturer KASTO to help separate additive manufactured titanium parts from their base plate. The Donauwörth factory additive manufactures titanium shafts for locking aircraft doors. When printing of the components is finished, they must be separated from the 400 mm x 400 mm titanium baseplate, a function that the KASTOwin amc has been specifically designed to perform with speed, efficiency and without damage.

The National Design and Research Forum in Bengaluru, India, has signed a Memorandum of Understanding (MoU) with metal 3D printing service provider and consultancy firm Wipro 3D. Together, the partners have committed to work on aspects of design for additive manufacturing (DfAM) and develop standards for the aerospace industry. The MoU states that the companies would also offer competency building and advisory programmes relating to additive manufacturing. NDRF Chairman, Dr M Annadurai stated:

“NDRF and Wipro 3D are joining together to create industry standards and generate design for additive manufacturing pedigree for aerospace systems.”

3D printing powers Toyota’s new race engine

A powerful new racing car has been developed using 3D printing for the 2020 season of the Castrol Toyota Racing Series (TRS), a premier open-wheel motorsport category held in New Zealand. Developed by Toyota GAZOO Racing New Zealand, the Toyota FT-60 engine features carbon-reinforced 3D printed components supplied by composite engineering solutions provider Scheurer Swiss. “It was possible only thanks to 3D printing to deliver the tailor-made Toyota FT-60 components of the test series in such a short time,” says Dominik Scheurer, CEO of Scheurer Swiss.

The Motor Trade Association of South Australia (MTA), in partnership with Sydney-based industrial automation firm Tradiebot Industries, has announced the launch of an Automotive Innovation Hub. Based at the MTA’s Training and Employment Centre at Royal Park, the hub will focus on providing industry 4.0 automotive skills through a selection of training programs. The hub also aims to allow the automotive industry to showcase R&D innovation in the service and repair sector. Tradiebot, which is helping to build an automated, 3D printed repair service for cars, was able to display its newly released 3D printed parts used for car repairs at the hub.

Mario Dimovski, CEO of Tradiebot Industries commented, “This is a perfect partnership and location to launch such a venture and kick start the local automotive service, repair and digital manufacturing industry in SA.”

Another new 3D printing facility has been established by the State University of New York (SUNY) at New Paltz, Urbahn Architects, and PC Construction, who have completed the building of a new $13.5 million, two-story 19,500-square foot Engineering Innovation Hub. The facility will house state-of-the-art 3D print prototyping labs to support the College’s new bachelor’s degree program in mechanical engineering. SUNY New Paltz was awarded $10 million through the NYSUNY2020 Challenge Grant to support academic programs that translate directly into economic development in New York State.

Farsoon implements Siemens software for open platform additive manufacturing

The latest round of business updates sees Farsoon Technologies, a Chinese manufacturer of SLM and SLS 3D printers, and Siemens China enter into a strategic partnership aiming to create a framework for integrated industrial additive manufacturing solutions. In recognition of the collaboration, Farsoon will implement Siemens’ end-to-end software and “Digital Twin” solutions into its open platform industrial additive manufacturing systems.

Weerg, an online 3D printing and CNC service provider, has acquired 6 3D printers from the HP Jet Fusion 5210 series, in what has been confirmed by Davide Ferrulli, Country Lead 3D Printing HP Italia as “the largest single order ever placed at EMEA level.” Previously, Weerg already had an installation of HP Multi Jet Fusion 4210 3D printers in order to fulfil its customer orders.

Rolf Lenk, a German manufacturer of industrial tools and machinery, has ordered a second arc 3D metal printing (3DMP) system from GEFERTEC at the EMO 2019 show in Hanover. Last year the company had acquired the GEFERTEC arc605 system to expand its services within metal additive manufacturing. Now, it has purchased the arc405 3D printer after the success it generated with the first machine. “We are delighted that our early investment into 3DMP as the new industry standard bears fruit so quickly,” states Rolf Lenk CEO Gregor Sodeikat.

“The workload for our first arc605 proved to be so tremendous right from the start that we are happy to invest into a second machine – an arc405 this time – by now already.”

3DGence, a Polish 3D printer manufacturer, has revealed that is has permanently reduced the prices of two of its machines; the 3DGence DOUBLE P255 and 3DGence ONE 3D printers, by €861 ($947). Furthermore, 3DGence has also opened a new e-shop for customers in the European Union, through which the reduced 3D printers are available to purchase.

BCN3D Technologies, a Spanish 3D printer manufacturer, is now including the Magigoo glue from chemical and materials R&D startup Thought3D as the standard adhesive in the boxes of BCN3D printers, with the intention of improving end-user experience. The glue went through a six-month testing period where it was chosen ahead of other adhesives against criteria such as user safety, improved user experience (easy application and no-mess cleaning) and no restrictions for logistics.

“We initially released Magigoo in 2015 at the TCT Show in Birmingham. Based on customer feedback from a broad spectrum of users, we have iterated the product to what it is now. From the first formulation the users have been at the center of our efforts,” explained Dr. Keith M. Azzopardi, Co-Founder of Thought3D.

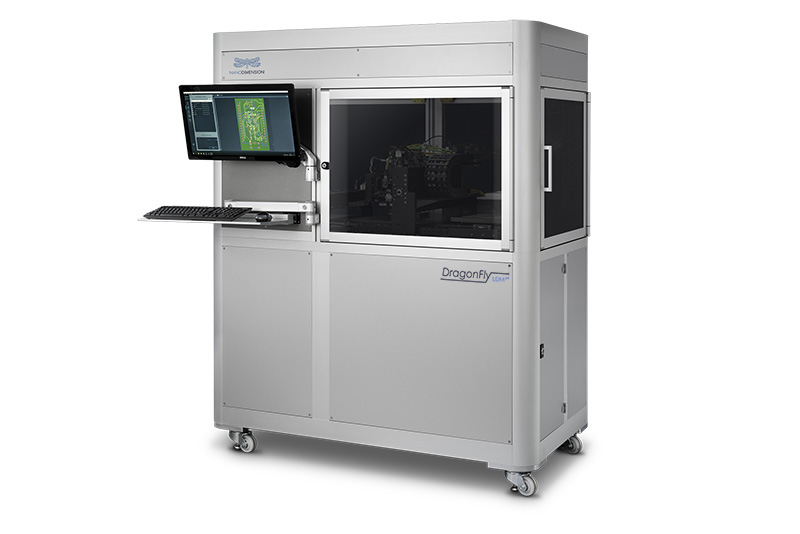

Israeli 3D printed electronics company Nano Dimension has announced the sale of an additional DragonFly 3D printer to a branch of the United States Armed Forces. This brings the total additive manufacturing systems sold to U.S. defense customers in recent weeks by Nano Dimension to four.

3D printed mini-heart

In medical, BIOLIFE4D, a biotechnology company from Chicago, has successfully 3D bioprinted a mini-heart. The achievement is a significant milestone for the company as it aims to produce a full-sized human heart viable for transplant. BIOLIFE4D bioprinted the miniaturized organ using a unique bioprinting algorithm and its proprietary bioink. The mini-heart is reportedly able to replicate some of the functions of a human heart. Previously, BIOLIFE4D was reported as the first company to have 3D printed human heart tissue.

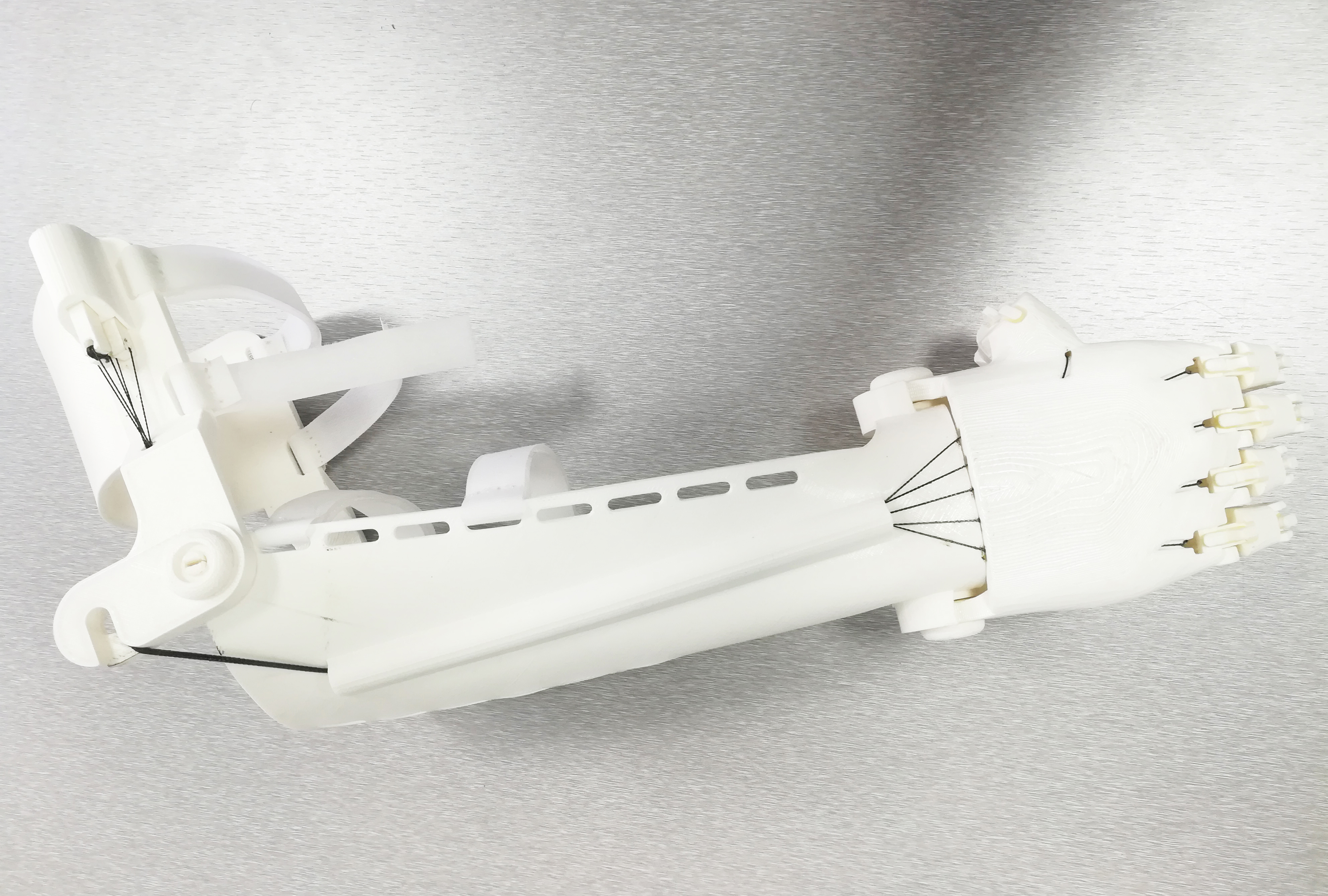

Italian 3D printer manufacturer WASP has revealed that its 3D printed orthopedic laboratory is now up and running at the University of Damascus in Syria. Last year the company had launched its Digital Orthopedic Laboratory giving patients access to custom 3D printed medical support devices. Jean Bassmaji, a Syrian cardiologist contacted WASP seeking to install the company’s Digital Orthopedic Laboratory in Syria to help care for the injured. Now, the Delta WASP 4070 Industrial and Delta WASP 2040 PRO 3D printers have been installed at a lab at the University of Damascus alongside a 3D scanner, a PC and some materials. “Finally, our dream has become reality,” comments Jean Bassmaji.

“The Orthopedic laboratory for Syrian mutilated people has been installed at the Faculty of Mechanical and Electrical Engineering in Damascus. Here about ten students (mostly women) are working and four teachers every day.”

Batch.works opens its doors to the public

Laticrete, a manufacturer of flooring and facade materials, has made an investment in 3D printing mortar technology. It is sponsoring Ball State University Design Innovation Fellow and assistant teaching professor Christopher Battaglia to create a 3D printed concrete shell of 110 unique panels. It will be assembled upon a pavilion constructed using a 3D printable mortar prototype that Laticrete has developed and plans to launch in 2020. The project is among 18 other temporary installations at Exhibit Columbus, a design exhibition in Columbus, Indiana that kicked off on August 23, and will run until December 1 2019.

Elsewhere in design, Batch.Works, a London-based 3D printing service bureau, invited the public inside its East London headquarters from 14 – 22 September as part of the London Design Festival. Visitors will be able to observe the company’s production process as it 3D prints its selection of stationery and homeware. Batch.works is opening its micro-factory to the public to raise awareness of 3D printing’s potential to save space and energy, and its role as a more sustainable choice for brands and designers wanting to create products.

“Our mission is to show that local manufacturing is possible, even in a major city like London,” comments Batch.works founder Julien Vaissieres. “We want to open the eyes of the public, as well as local design studios, to the opportunities that 3D-printing offers, particularly in terms of the limited space it requires, and the reduced amount of waste it creates.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Sliced logo edited on image of Toyota FT60. Original Image via Scheurer Swiss/Toyota.