In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions in the additive manufacturing sector.

Today’s edition features a plethora of new 3D printing partnerships, additive manufacturing records, digital inventory offerings, and how 2020 has been summarised in the form of a 3D printed flaming dumpster.

Read on for the most recent updates from Fusor Tech, Makino, Filamentive, Alloyed, Selfi3D, Weerg, Crypto, Essentium, and others.

New 3D printing partnerships for ExOne, Additive Industries, Filamentive, and Würth

Kicking off this week’s round up of 3D printing partnerships is the news that ExOne has joined a consortium led by DNV GL, the world’s leading risk management and quality assurance society for the oil & gas and maritime industries.

ExOne will be participating alongside the likes of Siemens, Equinor, BMT Aerospace, XDM3D, and others, as the consortium embarks on expanding its integration of more additive manufacturing technologies, such as binder jetting.

“As manufacturers around the world move to new additive manufacturing technologies, it’s important that they have standards to ensure the quality of their AM parts and products,” said John Hartner, ExOne CEO. “Binder jetting technology already delivers many benefits to the oil & gas and maritime industries, and we’re eager to expand that reach with new quality standards. Our binder jetting technology can help manufacturers 3D print large or small parts in high volumes that bring them broad benefits.”

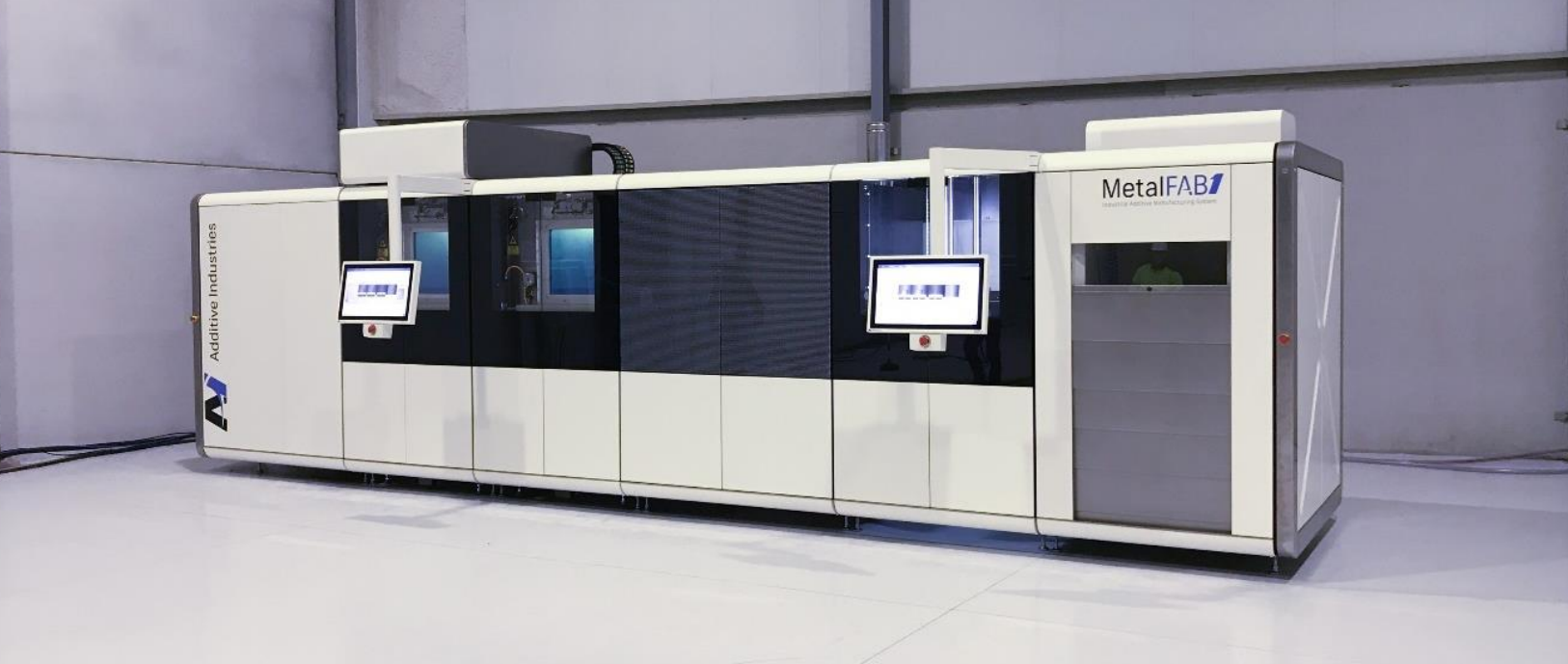

Meanwhile, Netherlands-based 3D printing firm Additive Industries has announced two new partnerships with additive manufacturing tech company Fusor Tech and milling and EDM machine tool specialist Makino.

Starting with the former, Fusor Tech has purchased Additive Industries’ MetalFAB1 system as part of the firms’ partnership to develop the Digital Spares market within the oil, gas, and petrochemical sectors. The MetalFAB1 3D printer will facilitate the manufacture of various metallic components for these sectors, chosen for its build size, modularity, speed, automation, and flexibility.

For its second partnership announcement, Additive Industries signed a letter of intent with Makino to embark upon a joint project to develop hybrid process chains integrating manufacturing and post-processing.

“Our engineering teams have established capabilities in complex 5-axis machining,” said Neo Eng Chong, CEO and president of Makino Asia. “We are very pleased to be working with an industry leader such as Additive Industries to accelerate the industrialization of 3D metal printing. The MetalFAB1 is a product designed for scaling and it’s a privilege to work with Additive Industries for the future of industrial metal additive manufacturing.”

Meanwhile, Würth Industry North America (WINA) – a subsidiary of the Würth Group, a German distributor of fasteners, MRO and safety equipment – has announced a partnership with oil giant Baker Hughes. Through the partnership, Baker Hughes will gain access to Würth’s 80,000-strong customer base and additive manufacturing services, and in return will deploy its digital inventory to enable customers to transition to cloud storage of digital designs, driven by machine learning algorithms.

“The collaboration with Baker Hughes broadens our offering in 3D printing and beyond,” said Dan Hill, CEO of WINA. “Our existing inventory programs gain a level of automation with no infrastructure change, and we can take our customers’ ideas fro prototype to small batch production to mass production at accelerated rates.”

Elsewhere, UK-based producer of sustainable 3D printing filaments Filamentive has teamed up with fellow eco-friendly filament firm 3D Printlife to enable its U.S. customers to purchase its materials with same day domestic shipping.

Filamentive will launch an initial five materials through 3D Printlife, including rPLA, PLA Matte, rPETG, rASA, and Carbon Fibre. The materials are compatible with 3D printing brands such as Ultimaker, Raise3D, Creality, XYZPrinting, and Flashforge.

“3D Printlife is proud to introduce Filamentive’s innovative line of sustainable materials to the US market,” said Buzz Baldwin, co-founder of 3D Printlife. “Their continued commitment to sustainability and quality in 3D printing is exemplary, and we’re excited to offer their filaments at a price that is still in line with European levels.”

Business updates from Alloyed and Selfi3D

Metal alloy specialist Alloyed has formalized its legal name after concluding a merger between Betatype and OxMet Technologies. The company aims to optimize advanced digital metal manufacturing applications through developing customized alloys, process controls, and 3D printing capabilities.

“We are really pleased to be making this final transition with the naming of the new company,” said Michael Holmes, Alloyed’s CEO. “It’s been pretty seamless in terms of the merger, because the technologies that we are bringing together complement each other so well and our customers can see the clear advantages.

“We know we have a unique stack of technologies for the manufacture of advanced metal components both by additive and traditional means.”

In the realm of personalized figurines, Spanish photo-sculpture producer Selfi3D has bought Stratasys‘ new J55 3D printer in order to improve the model realism and material stability of its products. The J55 will play a pivotal role in Selfi3D’s photo-sculpture offering, BeHero, a proprietary software enabling the creation of a 3D head from a single photograph.

“Having tested the J55, it was a clear upgrade in terms of the level of detail, color and material realism,” said Jorge Martín García, Selfi3D director. “The 3D printer also gives us a level of reliability and repeatability throughout the printing process, with color and detail as accurate and consistent as the original 3D CAD model.”

3D printer news

At last week’s Formnext Connect, 3D printer manufacturer and service provider Prodways announced the roll out of its ProMaker P1000X 3D printer to all industry players, after launching the machine in 2019. The machine is based on powder laser sintering technology and is compatible with more than seven materials in Prodways’ range, including flexible TPU, PA12, natural and glass-reinforced versions of PA11, and its new PolyPropylene PP1200.

Prodways also revealed it has won two new international clients as a result of the P1000X’s technical capabilities, which provides production speeds of up to two liters per hour and a printing volume of 32 liters.

“It is a major innovation for Prodways, which consistentlently develops its machines with a view to offering cutting-edge technologies to our clients,” said Alban d’Halluin, CEO of Prodways. “The two new contracts we have just signed in new markets are promising and confirm the development of 3D printing for industrial applications.”

Elsewhere, Italian 3D printing and CNC service provider, Weerg, has doubled its production capacity within a single operation by purchasing six additional HP Jet Fusion 5210 3D printers, and is on its way to reaching the European record for the number of systems installed.

In 2019, Weerg was confirmed to have undertaken the “largest single order ever placed at EMEA level”, and is one of the first companies to integrate HP’s automatic unpacking system, developed with German surface finishing solutions firm, the Rösler Group.

“In the last year we have seen an exponential growth in the demand for 3D printing, especially for large print volumes, to the point that it now represents around 70% of our production capacity,” said Matteo Rigamonti, founder of Weerg. “At a slightly higher price, 3D printing makes it possible to obtain large quantities of parts extremely quickly, avoiding the design limitations that characterize traditional processes such as injection printing.”

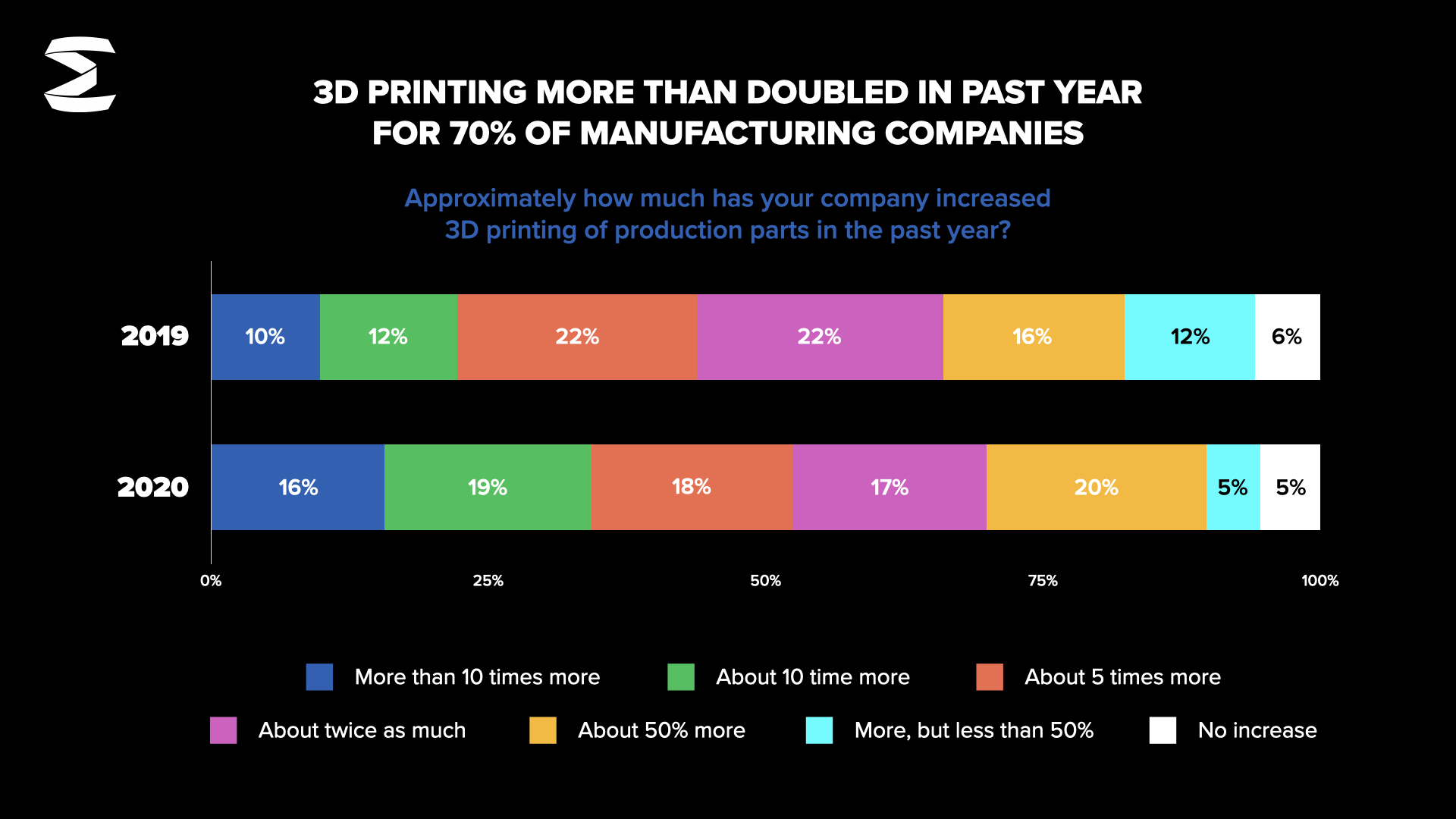

Essentium research reveals use of large-scale AM has doubled in past year

3D printing materials supplier Essentium has carried out independent research on the global current and future use of industrial 3D printing, revealing the use of large-scale additive manufacturing has more than doubled for 70 percent of manufacturers over the past year.

The research also concluded the number of firms shifting to using 3D printing for full-scale production had doubled to 14 percent in 2020, indicating how additive manufacturing is evolving from its prototyping phase. Out of the 169 survey participants, 90 percent believe the manufacturing sector could save billions of dollars in production costs once 3D printing technology matures further.

“The results of this survey show we’re at the beginning of radical change,” stated Essentium CEO and co-founder, Blake Teipel. “Additive is ready for prime time, and manufacturers are already moving into actual manufacturing to save manufacturing costs while building stronger supply chains that can withstand the worst type of unforeseen events – such as the pandemic.”

3D printing applications: weather balloons and recycled monuments

Open-source weather technology firm Telokanda has utilized the Telos blockchain platform alongside 3D printing to collect and transmit data on atmospheric pressure, temperature, humidity, and wind speeds from weather balloons in West Africa.

Each balloon is fitted with a small sensor, called a radiosonde, which is placed in a 3D printed box to enable it to be safely deployed with hydrogen. The radiosonde then transmits weather data to the Telos blockchain in real-time where it is stored as RAM, and this data is then sent to first responders to alert them to severe weather up to 12 hours in advance.

“The Telokanda weather balloon project is the new face for how emerging technologies can create a better and more equitable world,” said Douglas Horn, chief architect of the Telos blockchain. “There hasn’t been a push to launch radiosondes in West Africa for 15 years now, but with the development of 3D printing, cheap microcontrollers and the Telos blockchain, it’s becoming a reality.

“This project can quickly grow into one that will save lives and help prevent billions of dollars in weather damage.”

Meanwhile in Eindhoven, a 3D printed light monument honoring the region’s Second World War resistance heroes has been produced by Belgian machine development firm Colossus Printers and engineering and design agency OMD3D.

Claimed to be one of the largest 3D printed works of art in Europe, the monument has a diameter of 3.5 meters and a height of nearly six meters, and is produced from recycled plastics. More than 20,000 individually controllable LEDs were attached to a 1,500 kg steel frame and gray 3D printed columns. Grids of recycled PP were applied to the LEDs in order to give the lights a more diffused appearance, while the assembly materials were also printed from recycled plastics. Colossus was selected for the task of printing the monument after developing one of the largest transportable plastic 3D printers currently available around the globe.

The ‘Loom Light’ monument was designed by visual artist Titia Ex, who made the decision to employ 3D printing techniques in the production of the sculpture. The statue is located at the intersection of the former NRE energy park Eindhoven.

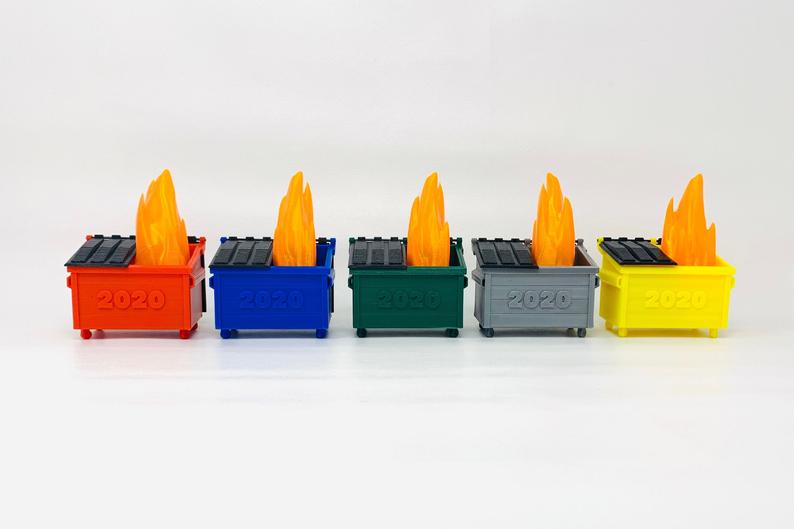

3D printed dumpster fire ornament sums up 2020

Finally, and offering some light relief, is Los-Angeles-based 3D printing shop RexRoi 3D printing, which is offering small 3D printed dumpster fire toys with ‘2020’ emblazoned on it and flames coming out of the top.

Available for purchase on online marketplace Etsy, each dumpster toy comes with a note that says “I thought this would be the best way to commemorate 2020. Hopefully it will bring you happiness and laughter.”

Equipped with an LED light, the toys can be purchased for upwards of $18.95 and are available in five colors. Not a bad ode to a very turbulent year…

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Be sure to subscribe to the Another Dimension podcast on your chosen podcast player to make sure you never miss an episode.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows RexRoi3D’s 3D printed dumpster fire toys with Sliced logo.