In this edition of CrAMmed Iranian researchers present a new 3D printing technique named Selective Laser Baking; new types of 3D printed bone formation patterns are explored by Sichuan University; and the capabilities of additive manufacturing for apparel is explored by Manchester Metropolitan University.

Knit one, 3D print two

“3D printing is an emergent technology which when combined with established textile processes offers the opportunity for a new method of textile production,” says Mark Beecroft, Senior Lecturer of Textiles in Practice at Manchester Metropolitan University (MMU).

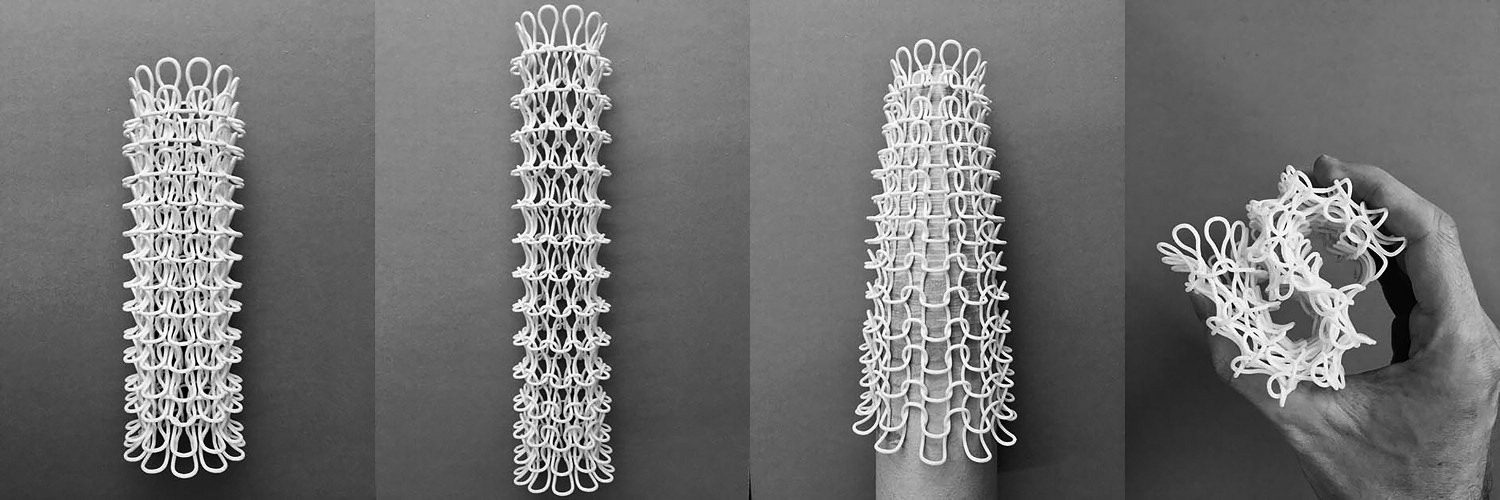

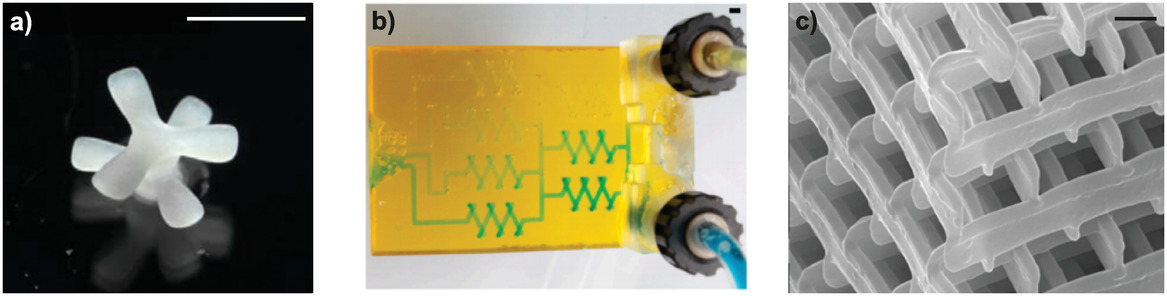

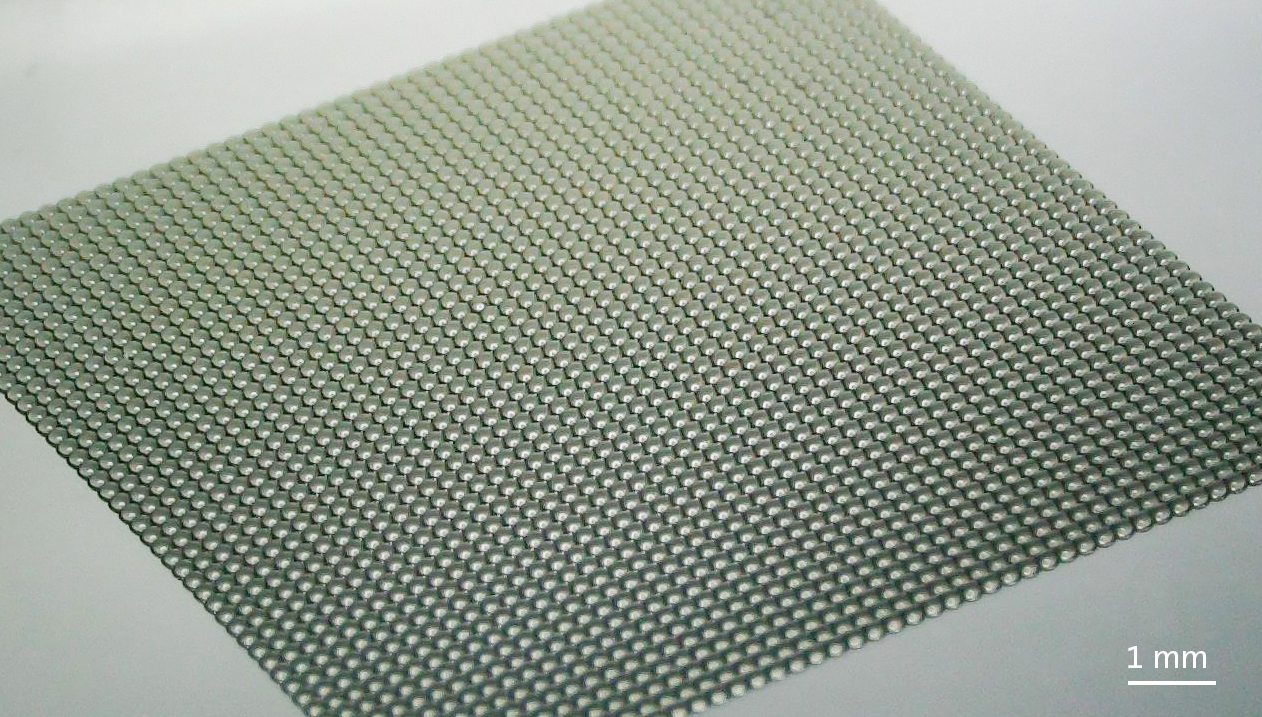

In the paper “Digital interlooping: 3D printing of weft-knitted textile-based tubular structures using selective laser sintering of nylon powder” published in Taylor & Francis Online, Beecroft demonstrates the potential of 3D printed tubular textile-based structures. Said structures, manufactured on the EOS Formiga P110 SLS 3D printer, can compress and extend, which can be developed for various technical textiles sectors such as sportswear and healthcare.

Shaking up FFF 3D printing

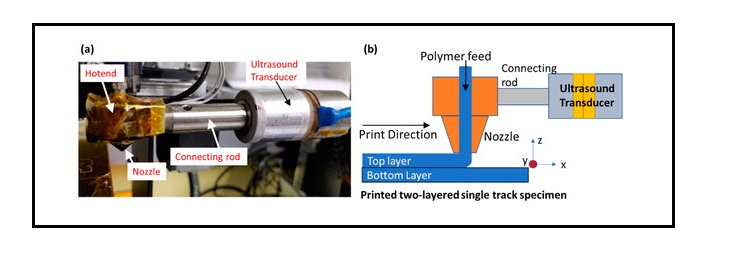

The University of Louisville has literally shaken up FDM/FFF 3D printing. Professor Keng Hsu and others from the University’s Department of Mechanical Engineering have explored the impact of ultrasonic vibrations on material extrusion in a study entitled “Effect of Ultrasonic Vibration on Interlayer Adhesion in Fused Filament Fabrication 3D Printed ABS” published in MDPI.

In doing this, the researchers sought to improve FDM/FFF 3D printing past rapid prototyping. The research states, “For the FFF process to advance into a manufacturing tool, its process and material characteristics, such as tolerance and accuracy, surface finish, as well as material property uniformity, need to reach a high level of maturity.”

As a result of 34.4 kHz ultrasonic vibrations during 3D printing, the team recognized a 10% increase in ABS layer adhesion compared to standard FFF 3D printing. This is attributed to polymer reptation – the thermal movement of entangled polymer chains – from the induced vibrations.

Also demonstrating the applicability of additive manufacturing, Tomasz Lusiak, Lublin University of Technology, and Robert Babel of the Polish Air Force Academy, used FDM/FFF 3D printing to create a model aircraft and analyzing its aerodynamic characteristics. The research, “The initial analysis of the aerodynamic characteristics of a 3D printed model of an aircraft” is published in the Journal of KONES.

Medical research and 3D printing

Published in The Royal Society of Chemistry, the study“Modification of 3D printed PCL scaffolds by PVAc and HA to enhance cytocompatibility and osteogenesis,” from Sichuan University researchers have discovered two new types of bone formation patterns.

The team, which includes research associate Ma Jianyi from the Institute of Atomic and Molecular Physics, discovered these formations by using 3D printed scaffolds from personalized CT data exhibiting bone defects. The research states:

“With the help of 3D printing technology, clinicians can fabricate scaffolds of different size, specific shape and porosity.”

In medical imaging, Kamarul Amin Abdullah from the University of Sydney, a researcher in the Discipline of Medical Radiation Sciences submitted a thesis called “Optimisation of CT protocols for cardiac imaging using three-dimensional printing technology”.

Materials and micro-3D printing

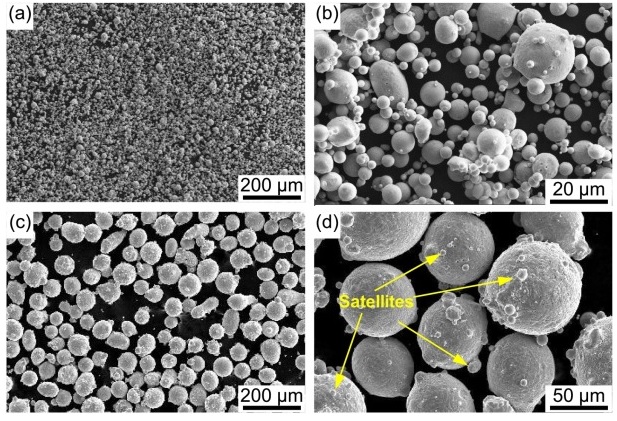

As metal additive manufacturing progresses, so must its materials. In the first detailed report on Electron Beam Melting (EBM)-built single-phase high entropy alloy (HEA) parts, researchers from the Singapore Institute of Manufacturing Technology (SIMTech) and Nanyang Technological University (NTU) have experimented with the mechanical properties of such metal powders.

The first author of the paper entitled “Additively manufactured CoCrFeNiMn high-entropy alloy via pre-alloyed powder” published in ScienceDirect, is Pan Wang, a researcher in Materials Science and Processing at SIMTech.

Also in materials development, Frederik Kotz of the Institute of Microstructure Technology (IMT) of the Karlsruhe Institute of Technology (KIT) and a team of German researchers have experimented with the chemical and thermal stability of 3D printing resins.

In the study,“High‐Performance Materials for 3D Printing in Chemical Synthesis Applications” published in Advanced Materials, transparent silicate glasses, ceramics, and fluorinated polymers are used to produce highly stable 3D‐printed chips, further enabling technology for miniaturization.

Furthermore, accepted for publishing in Rapid Prototyping Journal, the article “Fabrication of 3D microfluidic structure with direct Selective Laser Baking of PDMS” from the K.N. Toosi University of Technology, Iran, presents a new 3D printing technique called Selective Laser Baking (SLB). SLB processes Poly Dimethyl Siloxane (PDMS), biocompatible material for 3D printing structures of microfluidic devices.

Similarly, Nanoscribe, a German pioneer in high-precision additive systems, has presented its entire process chain, including the new Photonic Professional GT2 3D printer at the SPIE Photonics West trade fair in optics and photonics, in February.

Are any of the teams mentioned above your Research Team of the Year? It’s your last chance to make your nominations for the 2019 3D Printing Industry Awards.

For more of the latest 3D printing research follow us on Twitter, like us on Facebook and subscribe to our newsletter. Join 3D Printing Jobs now for opportunities in academia.

Featured image shows the Crammed logo over compressed, extended, stretched and folded 3D printed knit structures. Image via Beecroft.